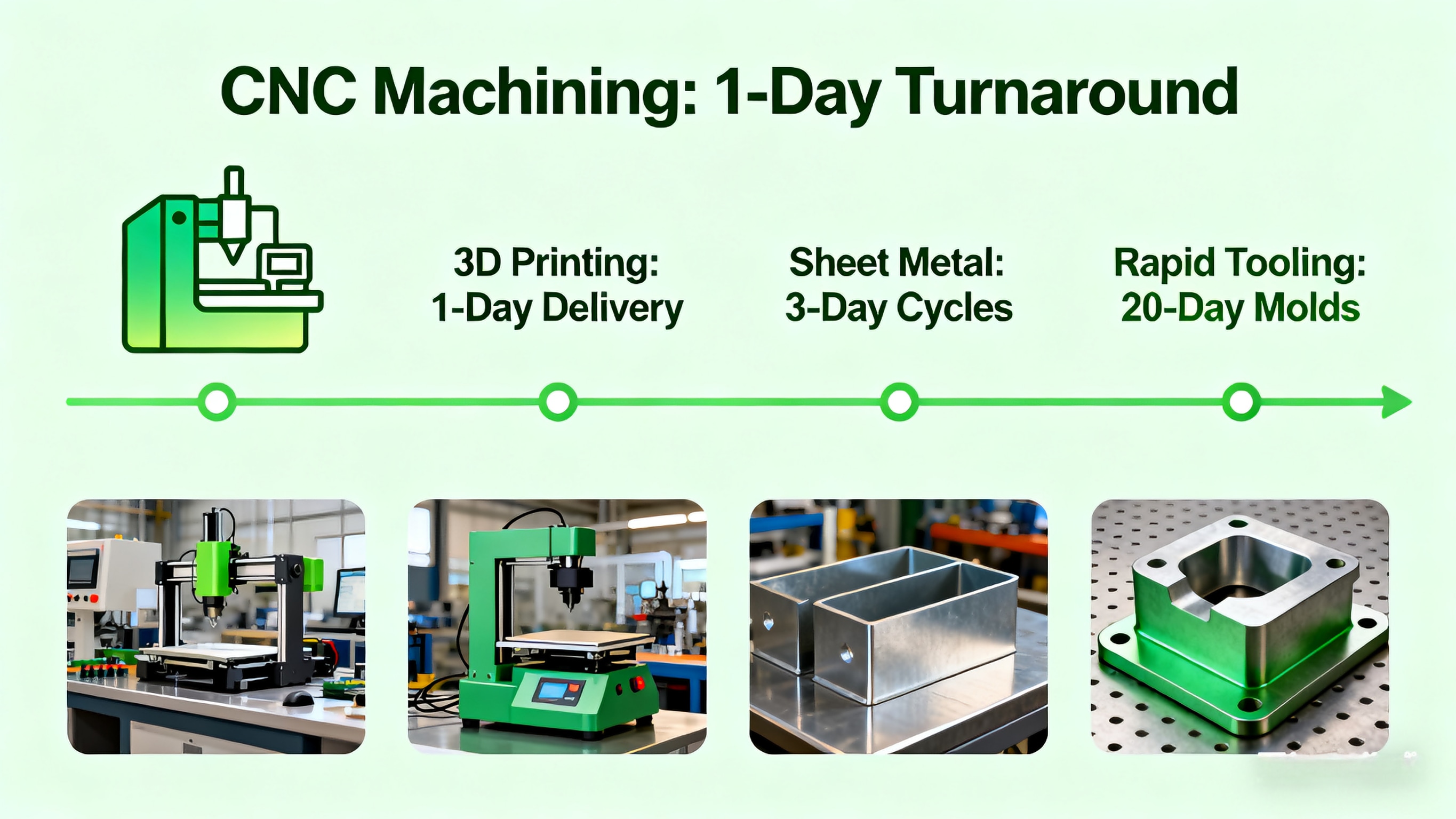

In a globalized world where time-to-market is the ultimate competitive advantage, one city has rewritten the rules of manufacturing velocity. While most manufacturing hubs measure production cycles in weeks or months, Shenzhen operates on a different timeline. Here, "one-week prototyping, two-week mass production" isn't a slogan—it's the operational standard that has created what industry insiders call Shenzhen's "speed hegemony." The Cluster Effect: Density as Strategy Shenzhen's electronics ecosystem represents the most concentrated manufacturing network on earth. Within a 50-kilometer radius, you can source every component, from specialized chips to custom molds, and access every service, from precision machining to complex assembly. By the numbers: Over 5,000 electronics suppliers in the immediate metropolitan area 80%+ of global electronics components available within 4 hours 1089 chip manufacturers in Bao'an District alone $213.6B in semiconductor industry output (2023) This unprecedented density creates what physicists would call critical mass—the point where mere proximity becomes transformative efficiency. The "Mother Factory" Model: Flexible Manufacturing at Scale At the heart of Shenzhen's speed advantage is an innovative production architecture we call the "Mother Factory" system. These are not traditional factories but manufacturing platforms that combine advanced production capabilities with deep supply chain networks. How it works: A central facility maintains core production expertise and quality control standards A distributed network of 700+ verified suppliers provides specialized components Digital integration enables real-time production coordination Resources scale dynamically based on order volume and complexity The results defy conventional manufacturing wisdom: 14 seconds to produce a laptop from components 1.6M+ smart devices annually from a single facility 30%+ improvement in yield rates for complex products The Digital Nervous System: Logistics as Competitive Advantage Speed means nothing without precision. Shenzhen's logistics infrastructure has evolved into a digital twin of the physical supply chain, with geospatial intelligence optimizing every movement. Logistics innovations driving efficiency: AI-powered routing that reduces transportation time by 18% Real-time component tracking across the supply network Digital freight matching that connects capacity with demand Integrated customs clearance that minimizes border delays Major global logistics players—from UPS to Maersk—maintain their regional headquarters in Shenzhen, creating a virtuous cycle of innovation and investment. Manufacturing as Service: The Platform Revolution Shenzhen's manufacturing capability is increasingly accessed as a service rather than a facility. Platforms like RapidDirect have productized manufacturing, offering: Standardized speed metrics: CNC machining: 1-day turnaround 3D printing: 1-day delivery Sheet metal fabrication: 3-day cycles Rapid tooling: 20 days for injection molds This "manufacturing as service" model has democratized access to world-class production capabilities, allowing startups and multinationals alike to leverage Shenzhen's speed advantage without massive capital investment. Global Replication: Exporting the Shenzhen Model The ultimate validation of Shenzhen's approach is its successful replication elsewhere. Hungarian facilities built on Shenzhen principles have produced 2M+ servers and workstations delivered to 69 countries. The pattern is consistent: where Shenzhen's density, digital integration, and flexible manufacturing models are replicated, dramatic reductions in time-to-market follow. The Strategic Implication For global businesses, Shenzhen represents more than a manufacturing location—it's a strategic acceleration tool. The 2-week production cycle isn't just faster; it enables: Rapid iteration based on real market feedback Reduced inventory risk through just-in-time production Faster capital recycling through compressed development cycles Competitive insulation through unmatched speed In an era where being first to market can determine category leadership, Shenzhen's "speed hegemony" has become perhaps the most significant structural advantage in global manufacturing. The question for international executives is no longer whether to engage with Shenzhen's ecosystem, but how to integrate its velocity into their global operations. Based on manufacturing data from Shenzhen Bureau of Industry and Information Technology, customs clearance statistics, and interviews with supply chain professionals across the Pearl River Delta region.

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat