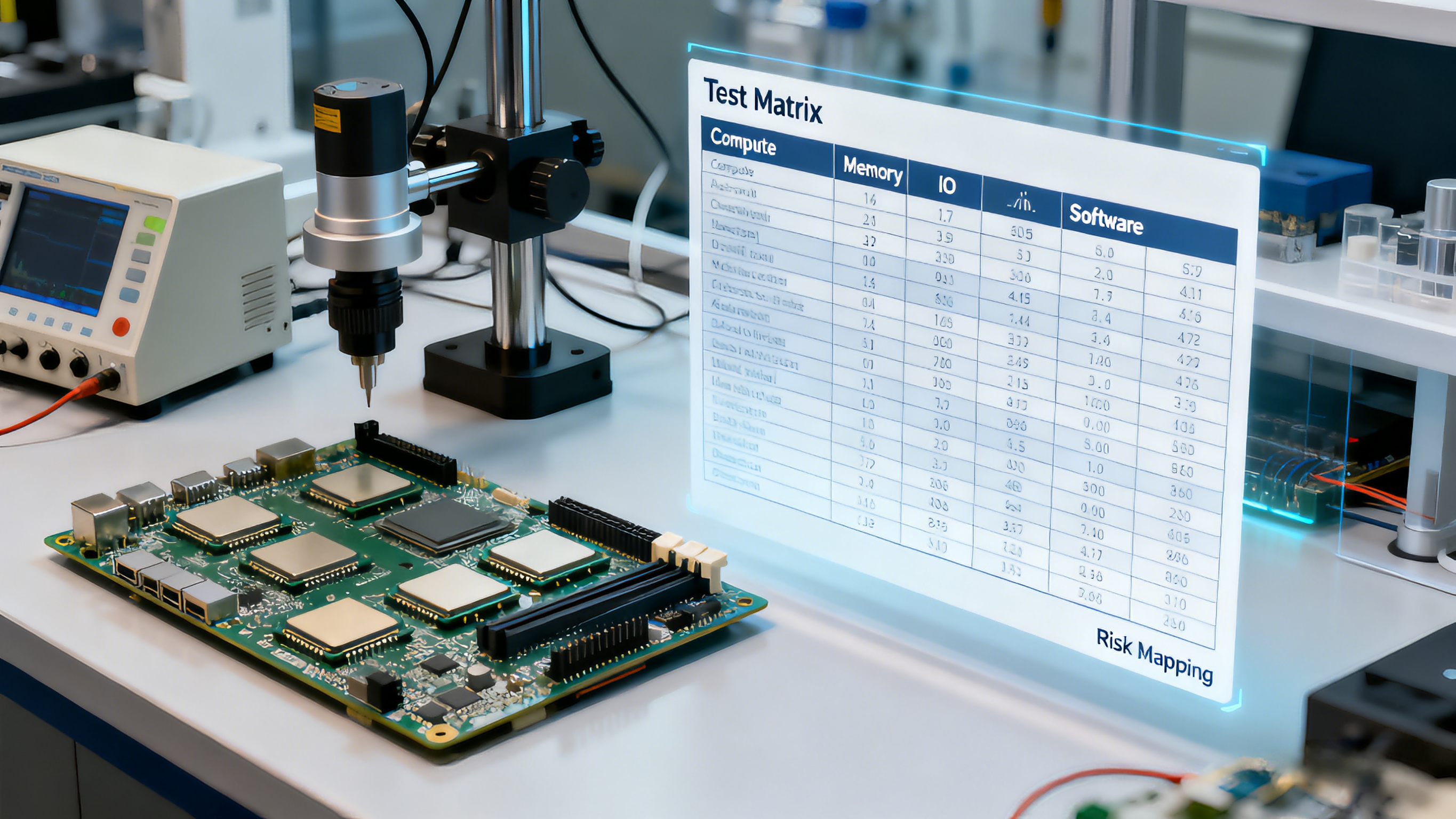

Modern hardware ecosystems are more complex than ever. Different CPU steppings, DDR5 PMIC variations, PCIe 4.0/5.0 signal integrity, NIC firmware behavior under SR-IOV… validation system The solution is not “more testing”— building a Test Matrix Here’s how engineers and teams can build one—even internally, with limited resources. 1. Start with the Core: Build a Hardware Test Matrix map A strong matrix organizes tests across four dimensions: (1) Compute Variants CPU models & steppings Microcode levels / BIOS versions Power profiles (PL1/PL2 behavior) (2) Memory Variants DDR4/DDR5 vendor brands PMIC versions Different timings & densities (8GB / 16GB / 32GB / ECC) (3) I/O & Expansion NIC firmware levels RAID/HBA controller BIOS PCIe Gen4/Gen5 GPUs & accelerators NVMe vendors (Phison, Silicon Motion, Samsung) (4) Software & OS Stack Linux kernel versions Virtualization (KVM, ESXi, Proxmox) Storage/file system combinations SR-IOV and DPDK stress tests can 2. Build a Small Internal Validation Lab (Even on a Budget) You don’t need a multi-million-dollar lab to achieve meaningful validation. practical minimal lab blueprint A. Compute Bench 2–3 motherboard platforms Multiple CPU steppings (same model, different batches) One chassis with adjustable power profiles Why it matters: B. DDR5/DDR4 Memory Wall 8–12 different DIMM vendor samples Micron / Hynix / Samsung OEM vendors Different PMIC versions ECC vs non-ECC Test across: Stability Cold boot Long-duration stress (MemTest 24–48h) C. PCIe Device Rack Keep a mix of: NVIDIA GPUs NICs (Intel, Realtek, Mellanox) NVMe from multiple vendors RAID/HBA cards Goal: D. Firmware Library Maintain baseline firmware for: BIOS NIC RAID SSD ME/TPM Document everything. This alone eliminates 30% of recurring issues. E. Automated Workload Suite Use open-source tools: Stress-ng iperf3 fio Prime95 Memtest lm-sensors logging DPDK packet generators Even small teams can simulate: High-load thermal conditions Memory boundary conditions PCIe saturation NIC virtualization workloads 3. What “Enterprise-Grade” Validation Looks Like Once a basic test lab is set up, upgrade the quality of testing—not just the quantity. cross-matrix CPU stepping A × DDR5 vendor B × NIC firmware C × Kernel D. ✔ Log temperature, frequency, and voltage patterns Not just whether it boots. ✔ Do long-duration tests Real failure often happens at 36–72 hours uptime. ✔ Validate firmware before pushing it everywhere Most regressions come from firmware mismatches. ✔ Track marginal power behaviors DDR5 PMIC + VRM drift leads to invisible performance drops. 4. Or—Work with a Manufacturing Partner Who Already Has a Full Validation Lab not every company has the capacity to test at scale This is where Shenzhen Angxun Technology provides a major advantage. How Angxun Adds Stability Before Your Hardware Ever Reaches You 2003 10,000+ m² factory area 500+ staff 50+ R&D experts 5 advanced SMT production lines SPI, AOI, ICT high-precision testing systems 300,000+ motherboard monthly capacity We integrate validation directly into manufacturing—ensuring that the hardware you receive has already passed matrix-level testing. Angxun Product Engineering Advantages ✔ High-efficiency aluminum thermal base Keeps DDR5 PMIC, VRM and PCIe zones at stable temperatures. ✔ All-solid capacitors Improves long-term power stability. ✔ Enhanced copper PCB design Ensures PCIe 4.0/5.0 signal integrity. ✔ Independent CPU power supply Reduces failure from stepping/microcode variance. ✔ Zero-burning protection circuit Protects during customer assembly and testing. ✔ Dual safety voltage/current stabilization Smooths load transitions and protects memory & PCIe devices. Angxun Company Advantages 23 Years OEM/ODM Eco-friendly materials CE / ROHS / FCC / ISO certified Fast global delivery Guaranteed after-sales support Whether you are building your own test lab —or you prefer pre-validated hardware to eliminate risk— Angxun provides the foundation for stable, high-performance platforms. Final Message If your team wants: A structured Test Matrix A blueprint for a scalable internal test lab Pre-validated OEM/ODM motherboard solutions Engineering-grade stability assurance

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat