Why modern enterprises need servers and motherboards with native Redfish support—and how Angxun helps make it real.

As data centers and cloud infrastructures expand, automation has become the only sustainable path forward. Teams managing hundreds or thousands of servers cannot rely on manual tools or proprietary interfaces.

This is why Redfish, the modern, open industry standard for hardware management, has emerged as a foundational component of large-scale automated operations.

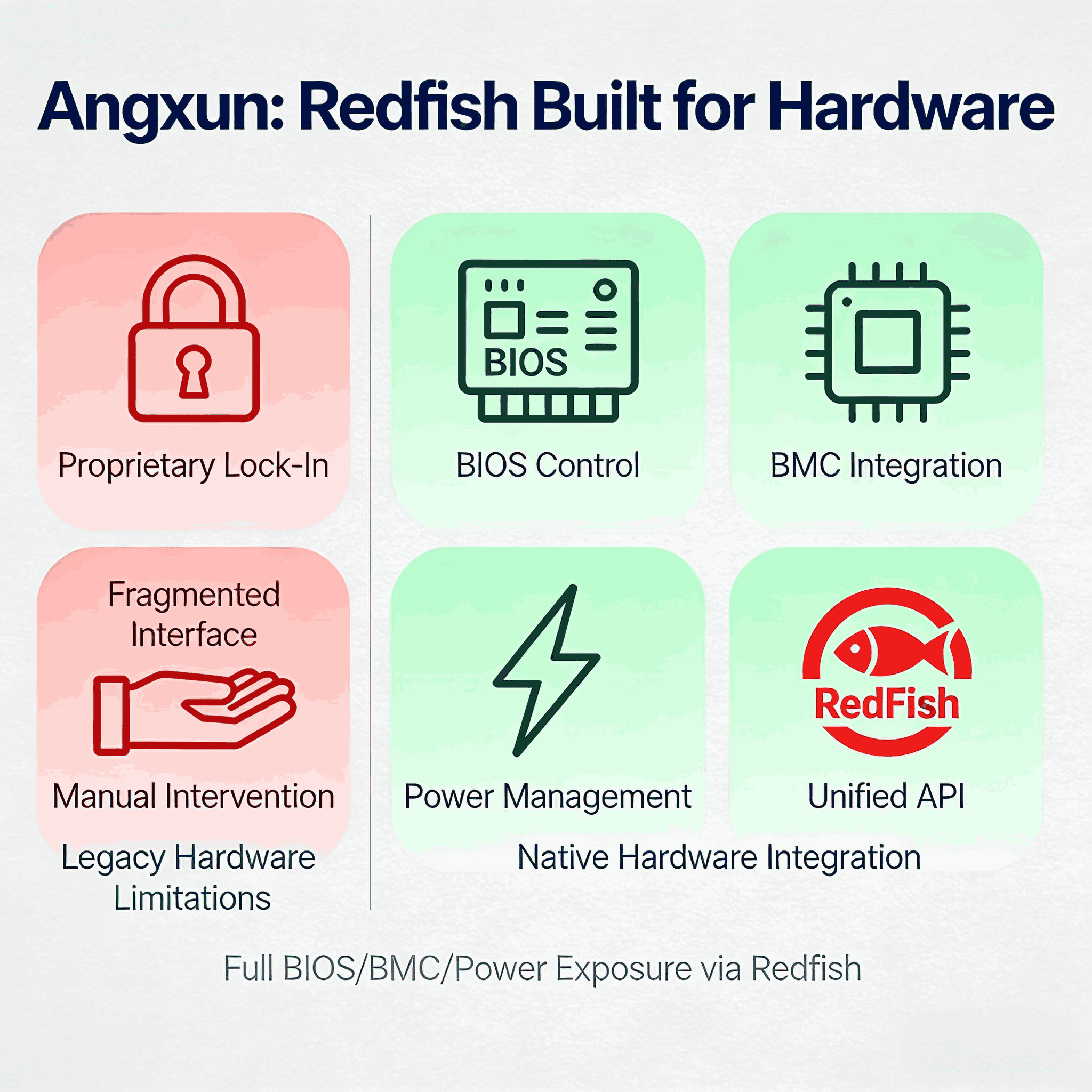

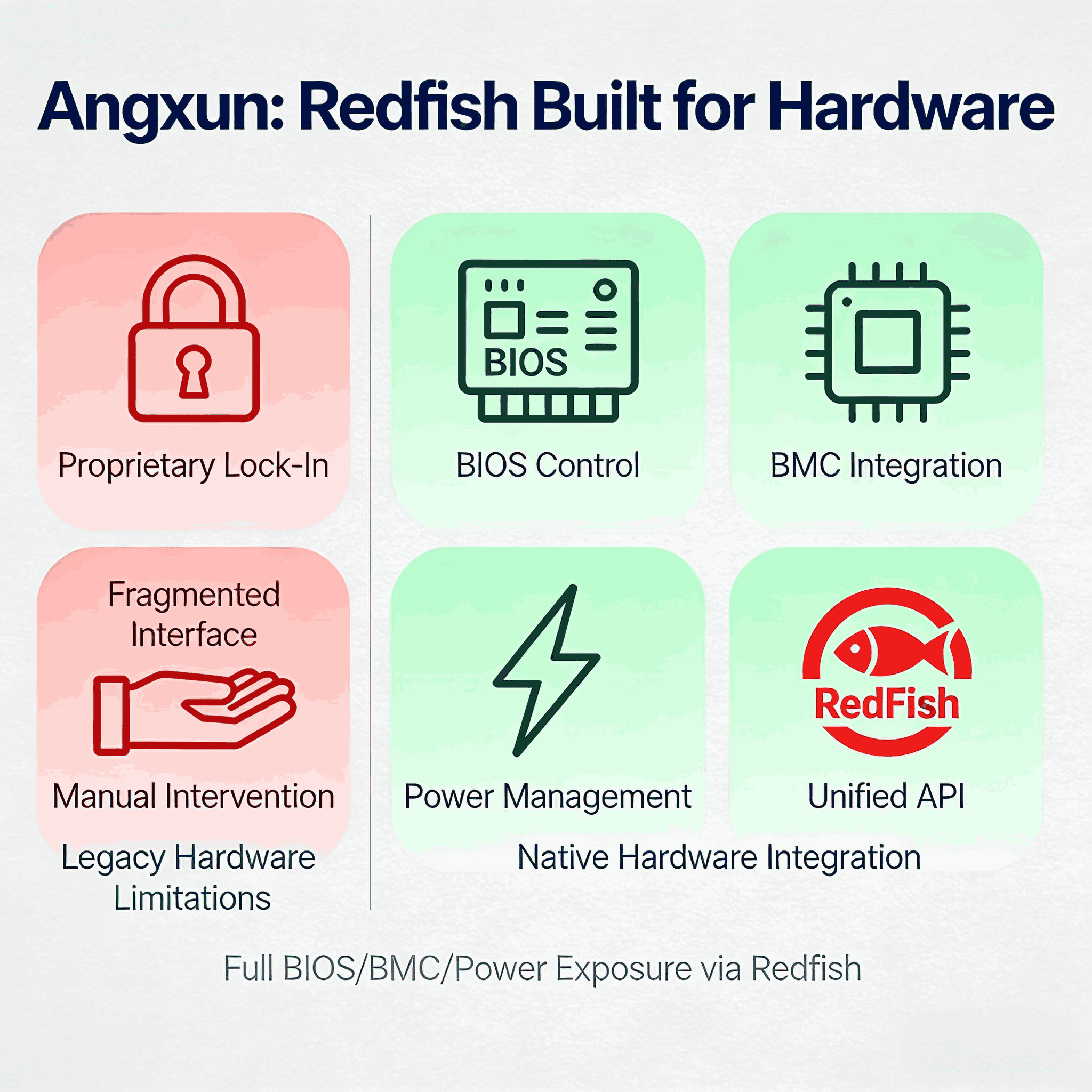

Yet many companies only consider Redfish from the software perspective.

The real impact begins at the hardware layer—specifically, whether the server motherboard and its firmware implement Redfish fully, reliably, and consistently.

This article explains how hardware-level Redfish support enables automated provisioning, configuration, monitoring, and lifecycle management—and how Shenzhen Angxun Technology helps enterprises accelerate toward fully automated operations.

Why Redfish Matters for Large-Scale Deployments

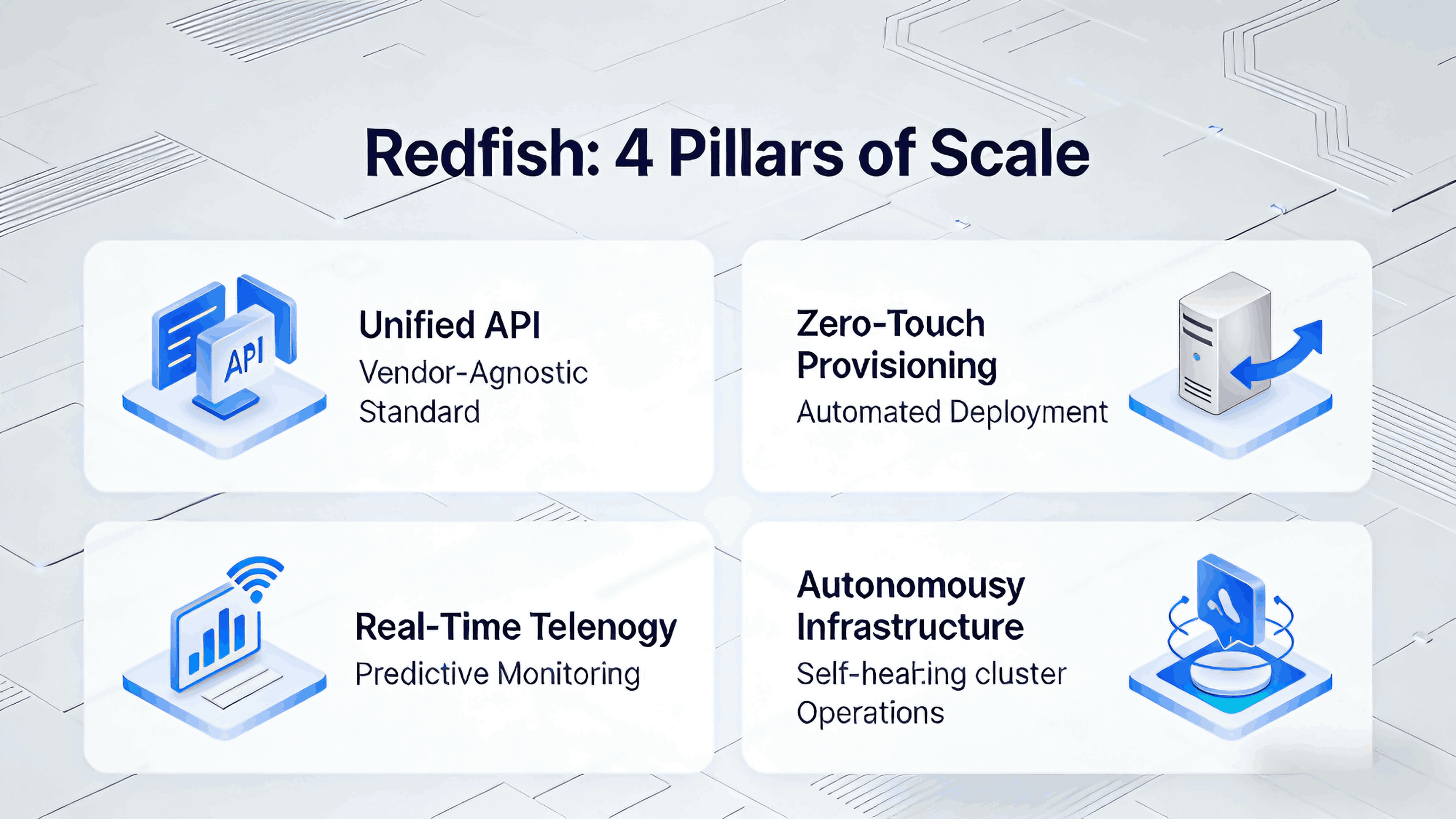

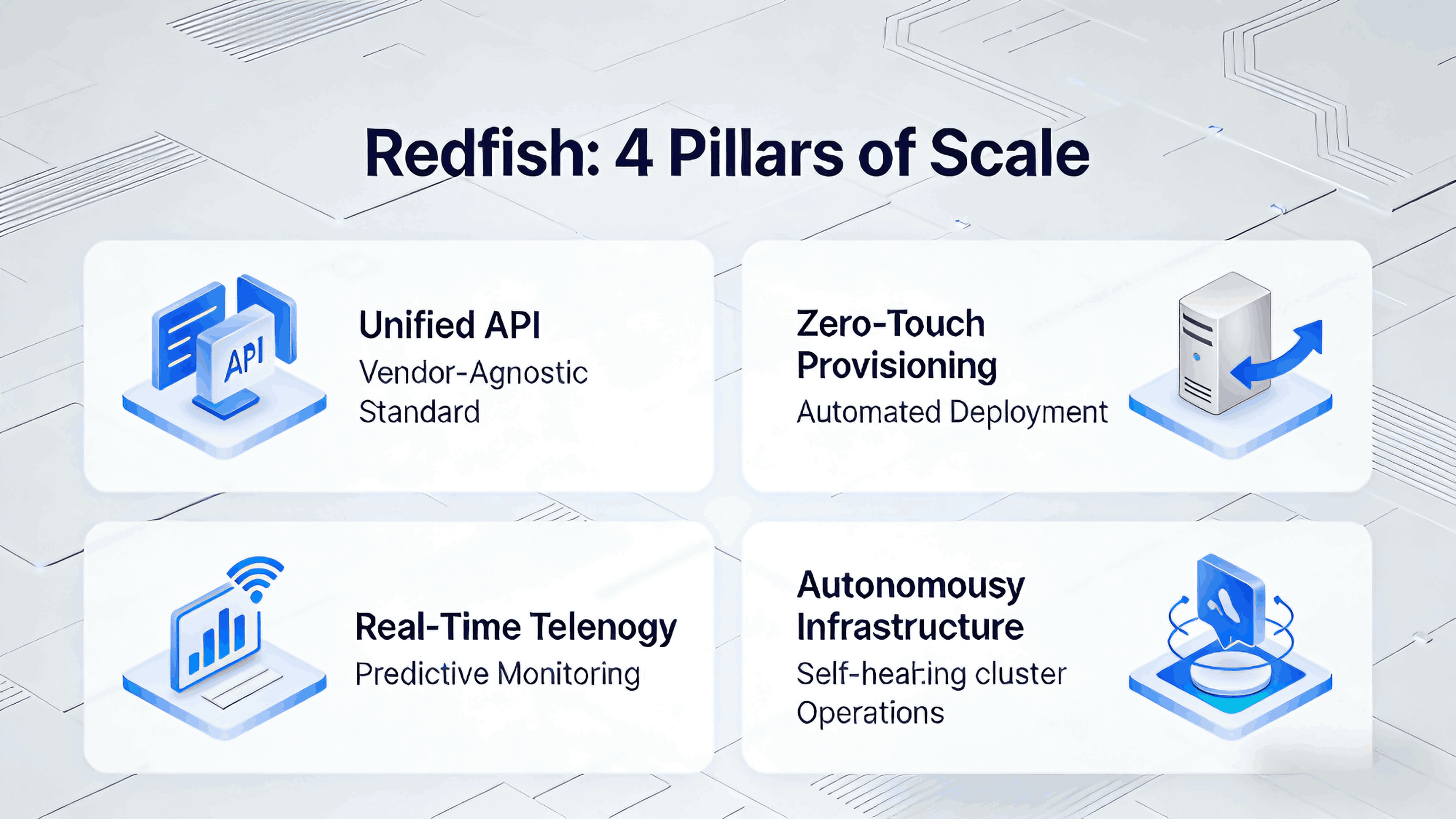

1. A Unified API for All Hardware Vendors

Traditional hardware management relied on proprietary tools that locked customers into a single ecosystem. Redfish solves this by providing:

A RESTful, JSON-based API

Human-readable schemas

Compatibility across vendors

Support for both bare-metal and virtualized environments

This standardization is essential for automation-driven architectures.

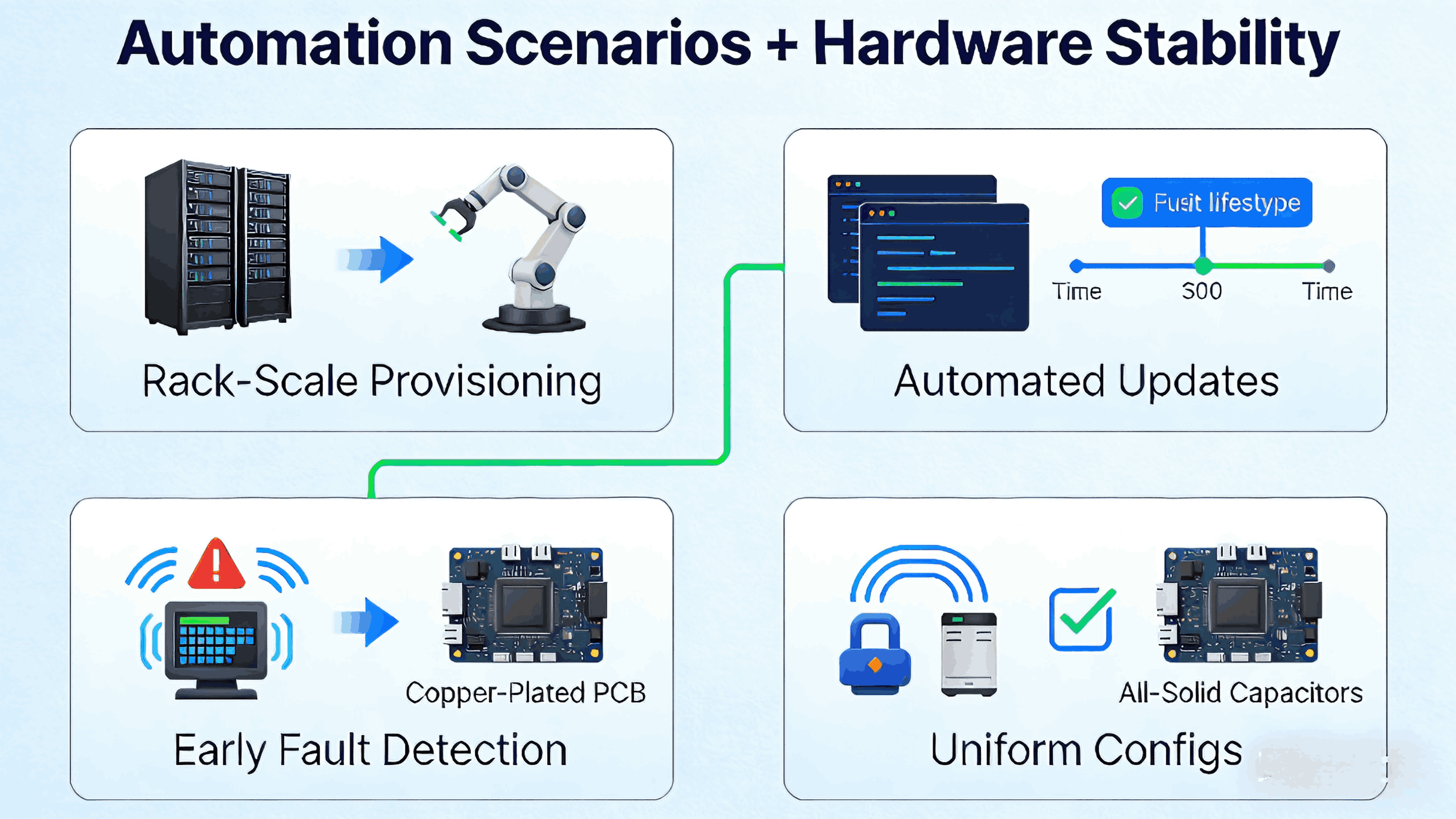

2. Fully Automated Server Provisioning

With Redfish integration at the motherboard level, organizations can automate:

This eliminates the last mile of manual touchwork that slows down cloud deployments.

3. Real-Time Visibility for Predictive Maintenance

Redfish provides fine-grained telemetry, including:

CPU/memory health

Temperature trends

Power consumption

Voltage/current stability

Storage & PCIe device health

Fan RPM & cooling performance

Enterprises can integrate these signals with monitoring platforms for early fault detection, reducing unplanned downtime.

4. A Foundation for Autonomous Infrastructure

With Redfish as the hardware control layer, organizations can build:

Self-healing server clusters

Automated firmware compliance

Large-scale IaaS provisioning pipelines

Immutable hardware configuration models

Zero-touch provisioning at rack scale

This is the direction hyperscalers and modern enterprises are moving toward.

How Angxun Implements Redfish for Enterprise-Grade Automation

Shenzhen Angxun Technology Co., Ltd., with 24 years of OEM/ODM experience, integrates Redfish support deeply into the design of its motherboards and edge computing platforms.

This is not an afterthought or partial implementation—it is fully aligned with enterprise automation requirements.

Key Capabilities Angxun Provides:

1. Native Redfish Support on Server-Grade Motherboards

Our hardware and firmware teams ensure:

Full schema compliance

Stable and predictable API behavior

Secure access control (OAuth, session limits, role policies)

Consistent behavior across board revisions

Long-term maintenance for production clusters

2. BIOS, BMC, and Power Control Fully Exposed to Redfish

Our platforms support Redfish for:

Power-on / power-off / reset

Remote BIOS setting changes

Boot device overrides

Fan and thermal policy control

BMC event logs and sensors

Firmware update workflows

This is critical for modern datacenter automation systems.

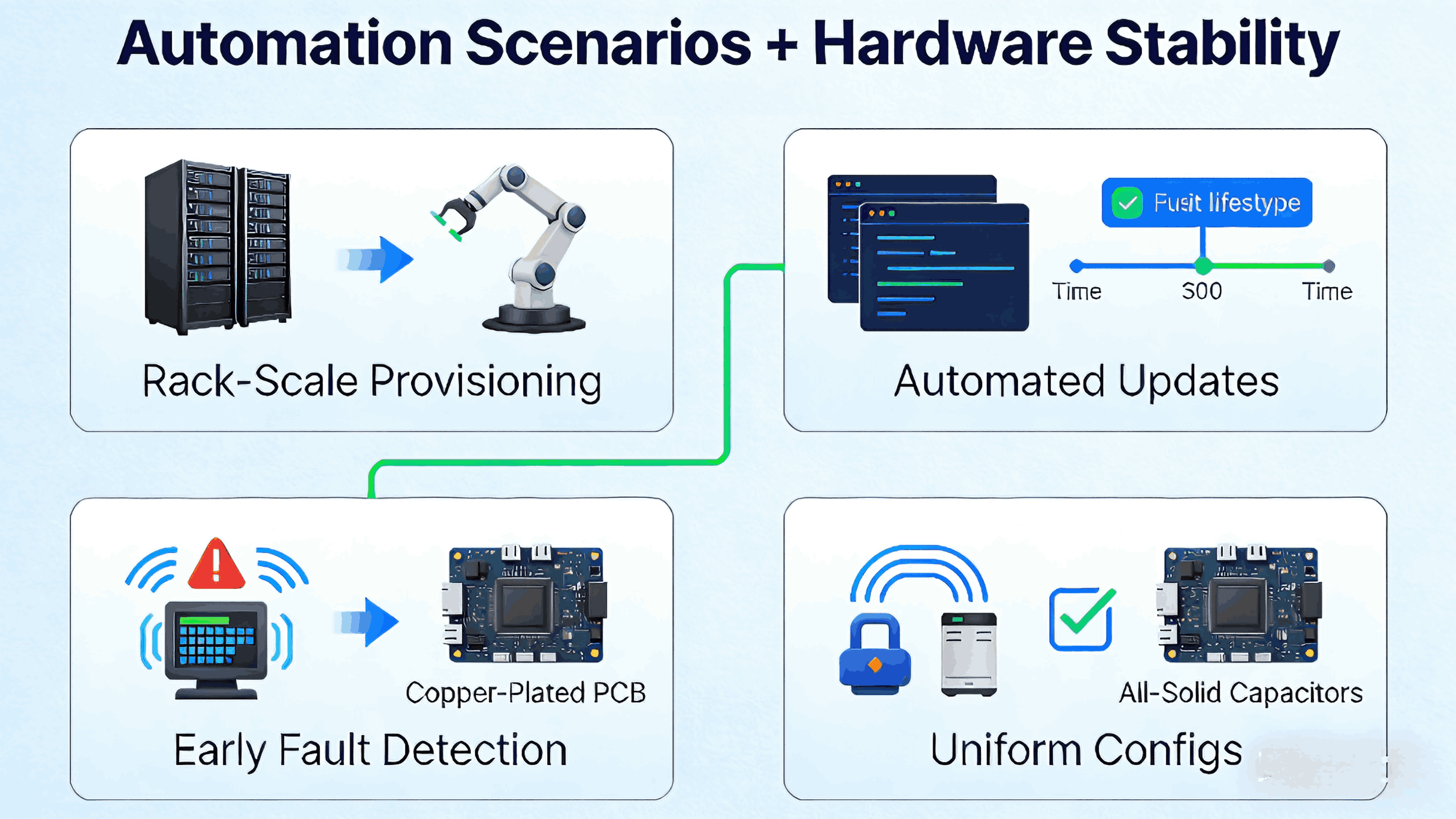

3. Hardware Built for Stability and Continuous Automation

Because Angxun designs and manufactures the boards in-house, our Redfish implementation is backed by robust hardware:

Aluminum-base cooling for lower thermal stress

All-solid capacitors for long lifecycle stability

PCB copper-plated layers for power integrity

Independent CPU power module for clean supply

Zero-burning protection circuits

Dual-stage voltage/current stabilization

Stable hardware results in predictable automation behavior—an essential requirement for Redfish-driven operations.

Angxun’s Manufacturing Strength Ensures Long-Term Redfish Reliability

Angxun provides hardware and firmware consistency across multi-year product cycles:

10,000 m² factory

5 advanced SMT production lines

High-precision SPI & AOI inspection

300,000 PCS monthly motherboard capacity

50+ R&D engineers (Intel/AMD platforms, BIOS, BMC, firmware)

CE, ROHS, FCC, ISO certified processes

This allows customers to scale Redfish-enabled infrastructure reliably and without SKU drift.

Real-World Value: Automation at Scale

✔ Zero-touch provisioning

Deploy racks of servers without physical intervention.

✔ Automated firmware lifecycle

Push updates across hundreds of nodes without service interruption.

✔ Predictive maintenance

Use Redfish telemetry to detect component failures early.

✔ Consistent configuration enforcement

Ensure BIOS and boot behavior remain identical across all nodes.

✔ Lower OPEX and fewer human errors

Automation replaces manual, ticket-driven operations.

For large-scale clusters, the ROI is substantial—and immediate.

Conclusion: Redfish is the Infrastructure Automation Foundation. Hardware Determines Its Success.

As enterprises modernize their data centers, the need for open, API-driven, automated server management becomes unavoidable.

With native Redfish integration, robust manufacturing, and strong firmware engineering, Angxun provides hardware platforms engineered for automation at scale.

If your organization is building cloud services, edge computing clusters, or standardized appliance-based solutions, Angxun can help you implement fully automated operations—from hardware provisioning to lifecycle management.