When cost pressures mount, the instinct for many brands is straightforward: negotiate harder.

The request to suppliers is simple: "Lower your price." While this may yield a quick win on a spreadsheet, it often sets the stage for long-term losses in quality, innovation, and trust.

There is a smarter, more sustainable path. The critical choice isn't between saving money and having quality; it's between two fundamentally different approaches: collaborative Value Engineering and adversarial Price Cutting.

Let's clear the fog.

Price Cutting: The Illusion of Savings

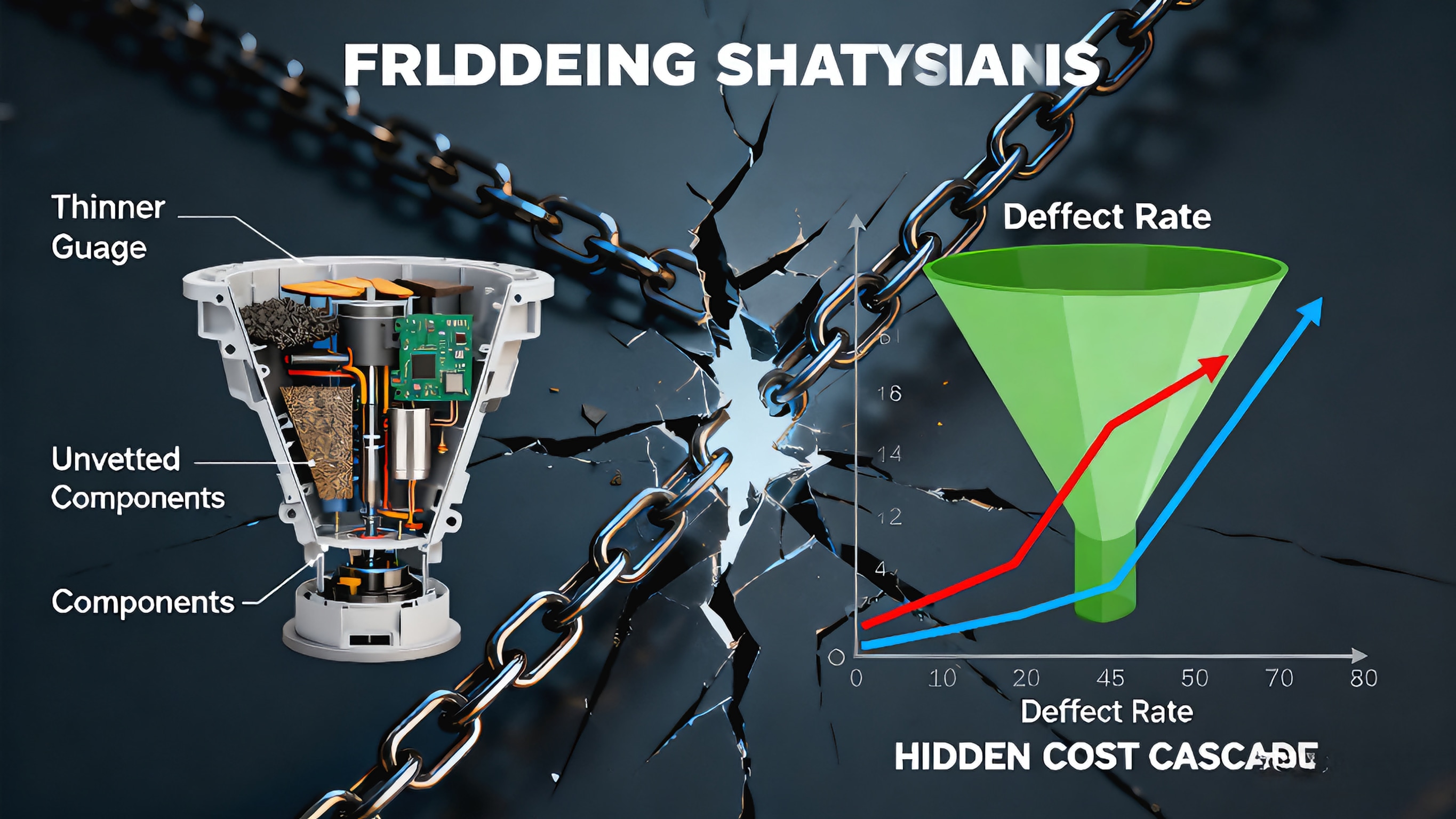

This is a zero-sum game. The brand wins a lower price, and the supplier absorbs the pressure. But how does a supplier "find" these savings? Often, it leads to:

Material Substitutions: Using a thinner gauge, a less durable finish, or a component from an unvetted secondary source.

Corner-Cutting in Labor: Rushing processes or reducing quality checks.

Eroded Supplier Profit Margin: This kills their ability to reinvest in R&D, modern equipment, and skilled talent.

The result? A product that looks the same on the drawing board but is fundamentally compromised. The hidden costs reveal themselves later: higher defect rates, customer returns, and brand reputation damage. You saved a dollar per unit, but now you're spending ten on warranty claims.

Value Engineering (VE): The Architecture of Mutual Gain

Value Engineering is a collaborative, data-driven process. Instead of asking, "How can you charge less?" we ask, "How can we *together* design and build this more intelligently, without compromising performance or customer experience?"

This is a partnership, not a negotiation. It involves:

Tear-Down Analysis: We physically disassemble the product to question the function and cost of every single component.

Design for Manufacturability (DFM): Our engineers sit with yours. Can we simplify this assembly? Consolidate three parts into one? Use a more readily available material that performs equally well?

Total Cost of Ownership (TCO): We look beyond the unit cost. A more reliable component might cost $0.10 more upfront but saves $1.00 in field service calls over the product's life.

The Choice is Yields Two Different Futures

The Price Cutting Path: A transactional, adversarial relationship focused on short-term gains, often leading to hidden risks and quality accidents.

The Value Engineering Path: A strategic partnership built on transparency and shared goals, leading to a more robust, cost-optimized, and innovative product.

At Angxun, we don't just manufacture; we co-create. We bring our production expertise to the design table early, not after the fact. We believe that the greatest cost savings are found in smarter designs, not in squeezed margins.

The next time you face cost pressures, ask your partners: Are you here to cut a price, or to engineer value?

I'm curious to hear how others are practicing VE in their partnerships. Share your experiences below.

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat