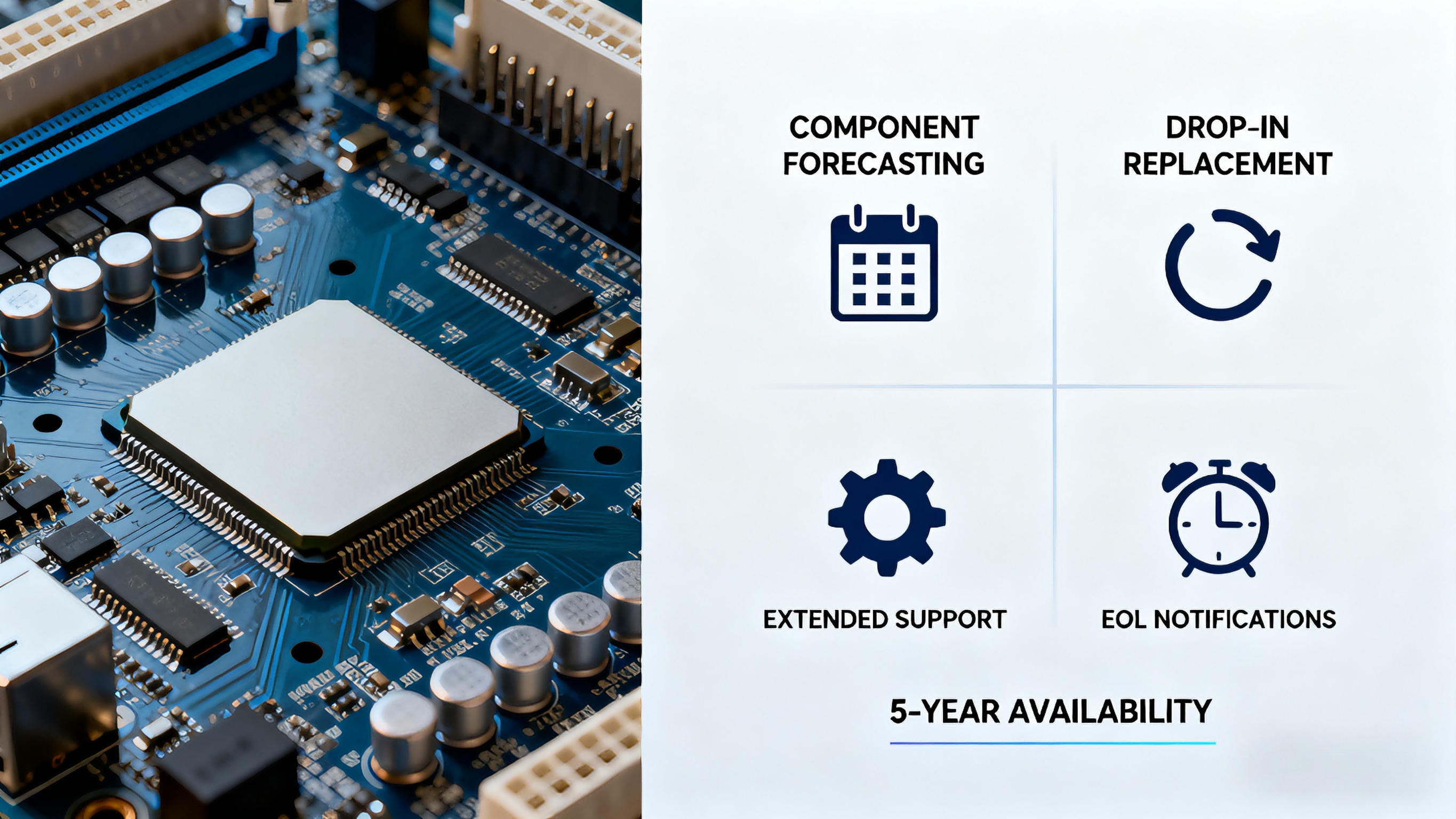

Why choosing the right motherboard today determines whether your system survives the next decade. We've all experienced it—that moment when a critical system fails because a key component is no longer supported, or replacement parts are impossible to find. In industrial automation, digital signage, network infrastructure, and enterprise environments, hardware lifespan isn't just about durability—it's about strategic planning from day one. The Hidden Cost of Short-Term Thinking Most organizations focus on upfront costs when selecting hardware. A $150 consumer-grade motherboard seems like a better deal than a $350 industrial board—until you factor in: Emergency replacement costs when a key system fails unexpectedly Downtime expenses from production halts or service interruptions Compatibility issues when mixing old and new hardware Security vulnerabilities from running unsupported platforms The semiconductor industry's rapid innovation cycle creates a cruel paradox: the very components that deliver today's peak performance become tomorrow's obsolete liabilities. The Component Discontinuation Crisis CPU and chipset lifecycles follow predictable patterns that most organizations ignore until it's too late: Consumer Platforms (Typical AMD Ryzen Desktop) Active production: 12-18 months Availability after discontinuation: 6-12 months Total usable lifespan: 2-3 years Industrial/Embedded Platforms (AMD Ryzen Embedded) Active production: 3-5 years Availability after discontinuation: 2-3 years Total usable lifespan: 7-10 years This divergence explains why industrial motherboards like the ASUS P10S-I Series continue to serve reliably for years after their consumer counterparts have disappeared from the market. Building Your 10-Year Hardware Roadmap Phase 1: Pre-Project Assessment (Months -6 to 0) Supplier Vetting Beyond Spec Sheets Investigate manufacturers' track records for long-term support Verify component substitution policies and notification processes Assess multi-region manufacturing capabilities (mitigates supply chain disruptions) Lifecycle-Aligned Architecture Select platforms with documented long-term availability (AMD Ryzen Embedded vs. desktop Ryzen) Choose form factors with upgrade paths (COM Express, SMARC) Implement modular designs that allow future component swaps Phase 2: Active Deployment (Years 0-5) Strategic Sparing Strategy Maintain calculated spares inventory based on failure rates, not just "a few extras" Implement rotation systems to evenly distribute operational hours across units Monitor early failure indicators through systematic testing Documentation Discipline Maintain comprehensive records of BIOS versions, drivers, and firmware Document all hardware modifications and compatibility validations Create detailed recovery procedures for quick replacement Phase 3: Lifecycle Extension (Years 5-10) Proactive Refresh Planning Identify successor platforms 12-18 months before component end-of-life Plan phased migrations to minimize disruption Budget for replacements before emergencies force your hand Adaptation Strategies Develop intermediate upgrade paths (additional RAM, storage, or expansion cards) Implement virtualization to extend application compatibility Create compatibility layers for older peripherals and interfaces Real-World Implementation: Industrial NAS Case Study A manufacturing client needed network storage for quality control image archival with 7+ year retention requirements. The solution combined: Hardware Foundation Industrial motherboard with AMD Embedded R-Series ECC memory support for data integrity Multiple 2.5GbE and 10GbE networking options PCIe expansion for future connectivity needs Lifecycle Management Quarterly component availability reviews with manufacturer Staged procurement to maintain 3-year inventory runway Pre-validated successor platform identified in year 4 Hot-swap compatible design for maintenance without downtime Five years into deployment, the system has survived two component discontinuations without operational impact, thanks to advance notifications and pre-positioned spares. Red Flags in Hardware Selection Avoid these common pitfalls that shorten effective lifespan: "Latest Generation" Addiction - Newest often means shortest production run as manufacturers rush to next iteration Proprietary Everything - Custom power connectors, non-standard form factors, and specialty mounting create single-source dependencies Feature Overkill - Paying for capabilities you'll never use wastes budget that could extend system lifespan Consumer-Grade Components - Designed for 1-3 year lifecycles, regardless of claimed "industrial" branding The Manufacturer's Responsibility At our factory, we've built our industrial motherboard, server board, and panel PC lines around lifecycle transparency: Component Longevity Forecasting - We provide 5-year availability projections for critical components Drop-in Replacement Planning - Successor boards maintain mechanical and electrical compatibility Extended Manufacturing Support - We continue producing legacy designs for key customers Transparent EOL Notifications - 12-month advance notice of component changes or discontinuations Your 10-Year Starting Point Next week, when you're evaluating that new deployment, ask these fundamental questions: Will this hardware platform be available and supported in 5 years? What's my documented migration path when components reach end-of-life? Have I budgeted for the total cost of ownership, not just the purchase price? Does my supplier have a proven track record of long-term support? The most elegant software solution, the most brilliant business logic, the most efficient workflow—all become useless when the hardware they run on reaches its inevitable demise. We manufacture AMD-based motherboards, industrial PCs, server boards, and NAS solutions designed with 10-year roadmaps in mind. Our industrial motherboard and panel PC lines specifically address the lifecycle challenges discussed here. Ask us about our long-term availability programs.

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat