When random crashes, performance anomalies, and ghost-in-the-machine failures become daily occurrences, you discover hardware integration's most insidious enemy: hidden compatibility issues.

As a motherboard ODM/OEM manufacturer, we've seen every type of hardware failure imaginable. But the most frustrating problems by far are those intermittent, illogical compatibility issues that defy reproduction. This real-world case consumed nearly a month of our engineering team's time but taught us invaluable lessons about hardware integration.

The Setup: Perfect Components, Failing Systems

Last October, we delivered a batch of AMD Ryzen Embedded V3000 series motherboards to a European industrial automation client. Every component passed rigorous testing:

Certified DDR5 memory (Samsung chips)

Recommended PSUs (800W 80Plus Gold)

Verified M.2 SSDs

Latest BIOS versions

Individual component testing passed flawlessly, but system integration revealed:

Random system freezes without BSOD errors

PCIe devices occasionally disappearing then reappearing

Memory tests passing while real applications crashed frequently

The Investigation: From Confidence to Despair

Week 1: Standard Troubleshooting

We began with established protocols:

Updated to latest BIOS versions

Tested different memory configurations

Swapped various power supplies

Tried different PCIe devices

Result: The problem persisted unpredictably. Systems might run stable for 48 hours or crash within 30 minutes.

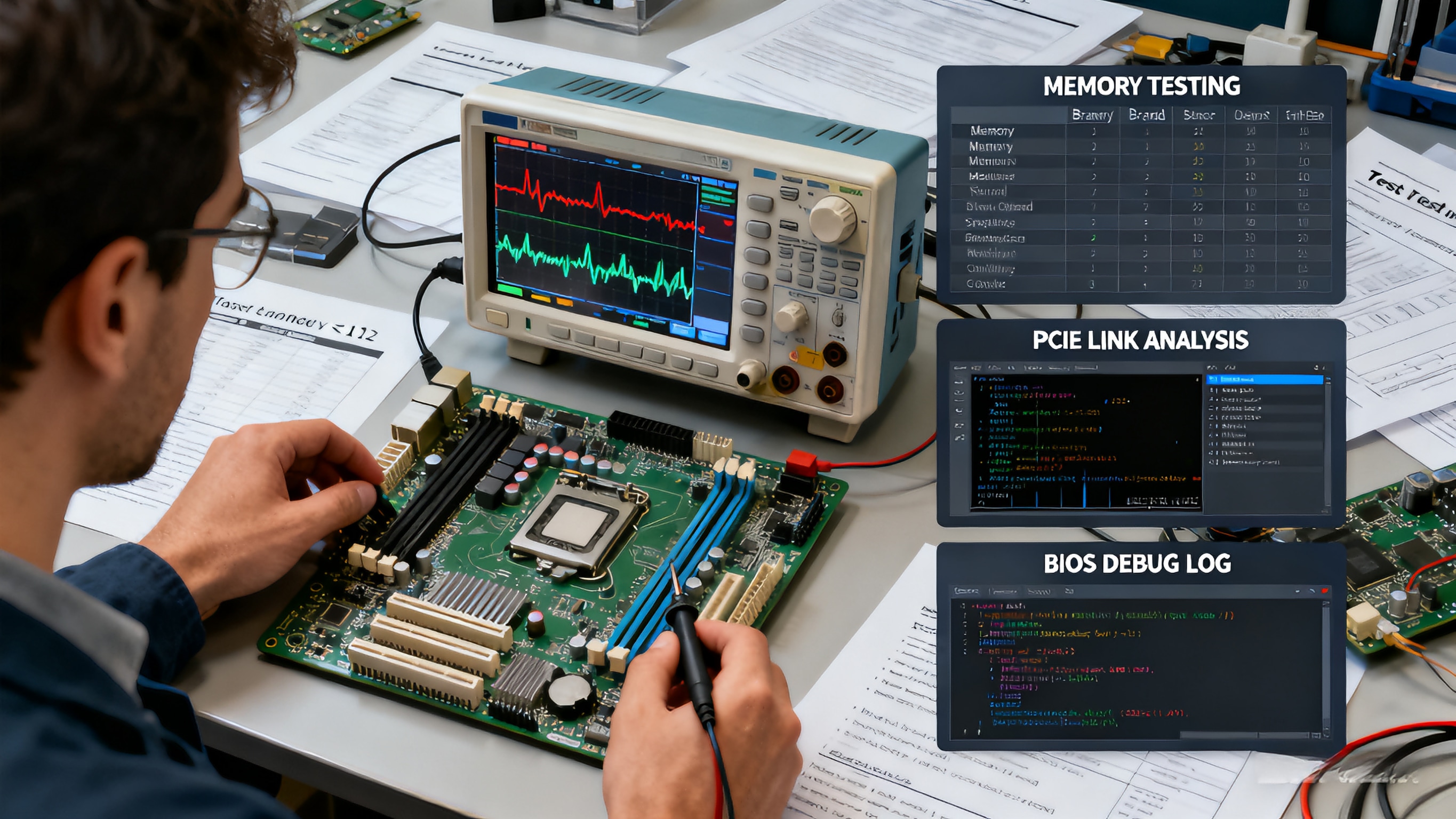

Week 2: Deeper Hardware Analysis

We escalated to advanced hardware diagnostics:

Monitored power delivery with oscilloscopes

Checked PCB impedance and signal integrity

Used thermal imaging to identify overheating components

Cross-tested motherboards from different production batches

Finding: All hardware parameters measured within specifications, but problematic boards showed abnormal voltage fluctuations during specific PCIe link training sequences.

Week 3: Divided Teams, Competing Theories

Our engineering team fractured into different camps:

Signal integrity team suspected PCIe clock jitter issues

Power delivery team blamed insufficient VRM transient response

Firmware team insisted it was AGESA code defects

We even started considering supernatural explanations—when you're desperate, every possibility seems plausible.

Week 4: The Breakthrough

The turning point came when we'd nearly given up. An engineer testing different memory brands noticed:

Brand A memory: System stable

Brand B memory (client-specified): Issues reproduced

Yet both passed all memory testing tools

The real culprit wasn't the memory itself, but a PCIe link state machine conflict during memory training.

Root Cause: The Delicate Dance Between AMD Infinity Fabric and PCIe

The perfect storm required these specific conditions:

Particular memory models (even when fully JEDEC-compliant)

PCIe 4.0 x4 M.2 SSD in specific slot

Concurrent PCIe x16 graphics card operation

Motherboard power states set to "balanced" mode

Root cause: During specific power state transitions, Infinity Fabric frequency adjustments conflicted with PCIe link training timing, causing some PCIe devices to stop responding.

This wasn't a single component failure, but the perfect storm of multiple edge cases.

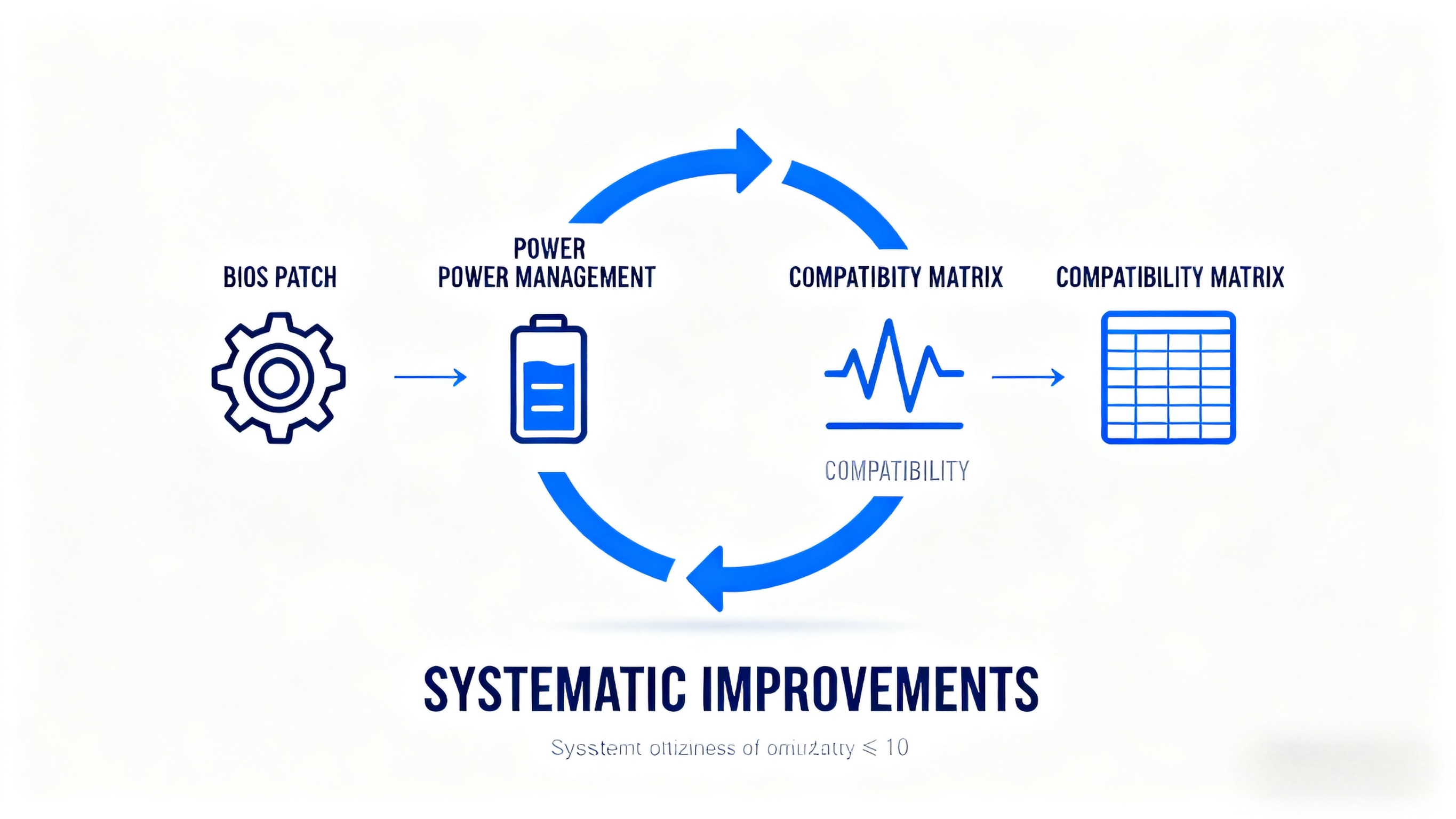

Solutions: From Firmware Patches to Testing Improvements

Immediate Fix:

We released a BIOS update featuring:

Adjusted Infinity Fabric power state transition timing

Increased PCIe link training timeout thresholds

Optimized memory training parameters

Long-term Improvements:

Enhanced Compatibility Testing Matrix

Testing beyond just "certified" components

Proactively testing different brand and batch combinations

Simulating real workloads beyond synthetic benchmarks

Power Management Stress Testing

Dedicated testing for power state transitions

Simulating power transients across different component combinations

Improved Customer Communication

Providing detailed known compatibility lists

Establishing rapid response protocols for weird issues

Practical Advice for Hardware Integrators

Based on this (and other painful) experiences, we recommend:

During Procurement:

Don't just check specifications: Two fully compliant components might still be incompatible

Demand comprehensive compatibility reports: Not just component lists, but combination test results

Choose suppliers with technical support capabilities: Engineering-level support matters when things go wrong

During Troubleshooting:

Systematic variable control: Change only one variable at a time, document every configuration

Watch for time-dependent patterns: Many compatibility issues relate to runtime or temperature accumulation

Test real workloads: Synthetic benchmarks might not expose problems

Don't ignore "minor" changes: Even small BIOS setting adjustments can trigger issues

For Prevention:

Build your compatibility database: Verify components in your actual application, even if suppliers say they're compatible

Keep debug hardware versions: Maintain hardware with extra test points for diagnostics

Establish technical channels with suppliers: Ensure issues reach engineering teams directly

How We Prevent Repeat Issues

This experience fundamentally changed our testing philosophy:

New testing protocols now include:

Cross-combination testing: Full matrix testing across brands, batches, and component types

Edge case simulation: Specifically testing component combinations at specification boundaries

Extended stability testing: Weeks of continuous operation rather than just 48 hours

Real-scenario simulation: Using actual customer applications instead of just testing tools

The Reality: There's No Silver Bullet for Compatibility

This painful experience taught us that in complex computing systems, compatibility issues are inevitable. What separates excellent suppliers from mediocre ones isn't the ability to avoid problems entirely, but rather:

How quickly they can identify and diagnose issues

Whether they have systematic, scientific troubleshooting methods

Their ability to learn from each incident and improve processes

Their commitment to transparency and accountability with customers

As a professional AMD motherboard ODM/OEM manufacturer, we've faced every type of compatibility challenge and built industry-leading testing and diagnostic systems. Whether you need desktop boards, industrial motherboards, server platforms, or embedded solutions, we have the experience to solve your toughest compatibility problems. Contact us to discuss your customization needs.

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat