Breaking the “Customization Black Box”

A Transparent Guide to BIOS & Hardware Customization

For many OEM, ODM, and solution providers, the idea of BIOS or hardware customization often feels like stepping into a “black box.” Requirements go in, prototypes come out—but what actually happens in between is rarely explained clearly.

This lack of transparency creates fear:

Will the changes break compatibility? Will the delivery be delayed? Will the firmware remain maintainable? Will production be scalable?

In reality, a well-structured customization process should be predictable, auditable, and aligned with your business goals—not a mystery.

At Shenzhen Angxun Technology, we’ve spent 24 years building a clear, engineering-driven customization methodology that takes you from requirement to mass production with full visibility.

Why Transparency Matters in BIOS & Hardware Customization

1. Prevent misunderstandings and hidden risks

Clear process mapping reduces rework, delays, and compatibility surprises.

2. Improve cross-team communication

When firmware teams, hardware engineers, procurement, and quality teams share the same process map, execution becomes smoother.

3. Protect long-term maintainability

Transparent customizations come with documentation, reproducible builds, and repeatable testing procedures.

4. Increase confidence for large-scale deployments

Enterprises and system integrators need visibility into every phase—from sourcing to BIOS tuning—to ensure reliability and continuity.

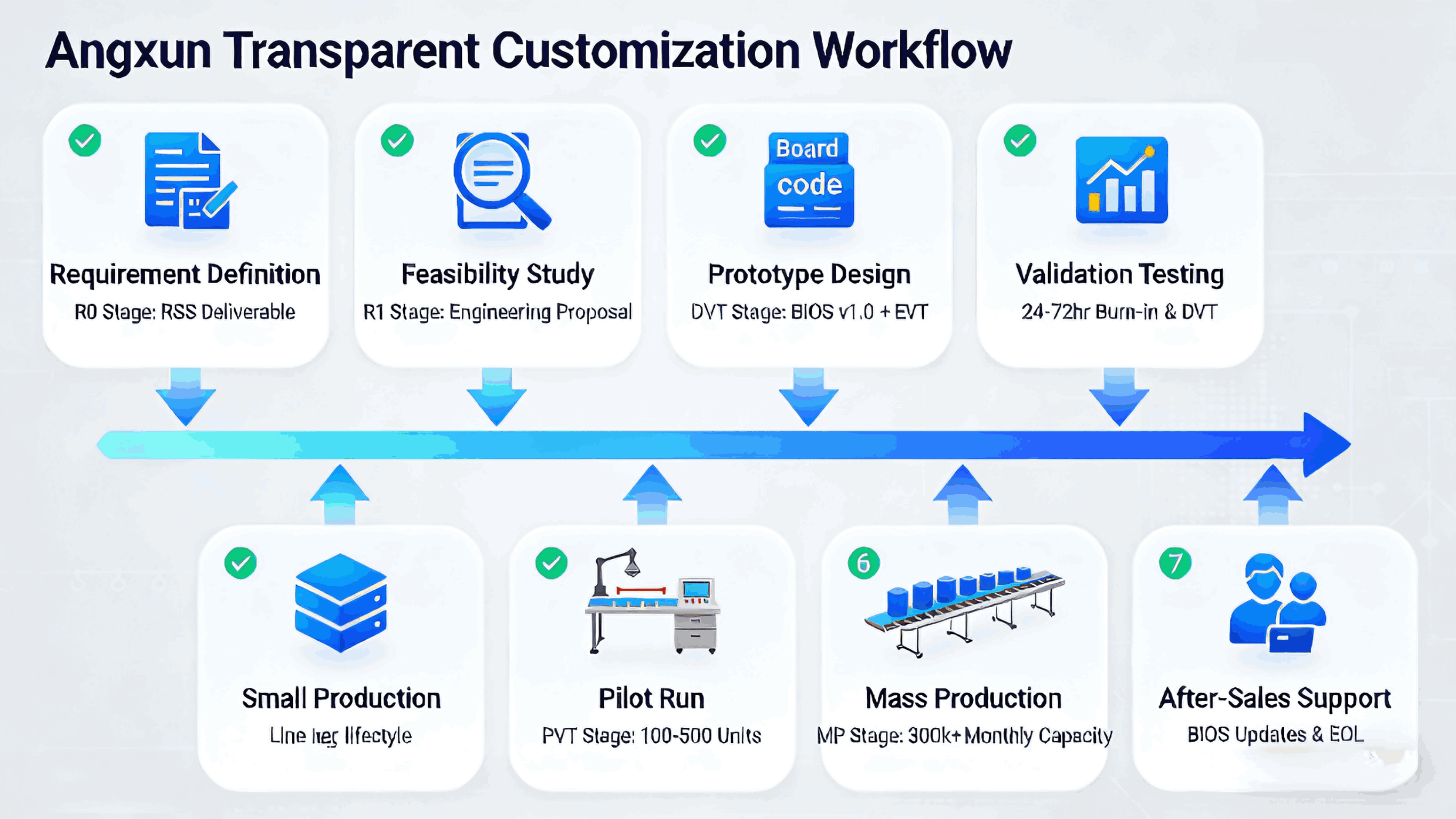

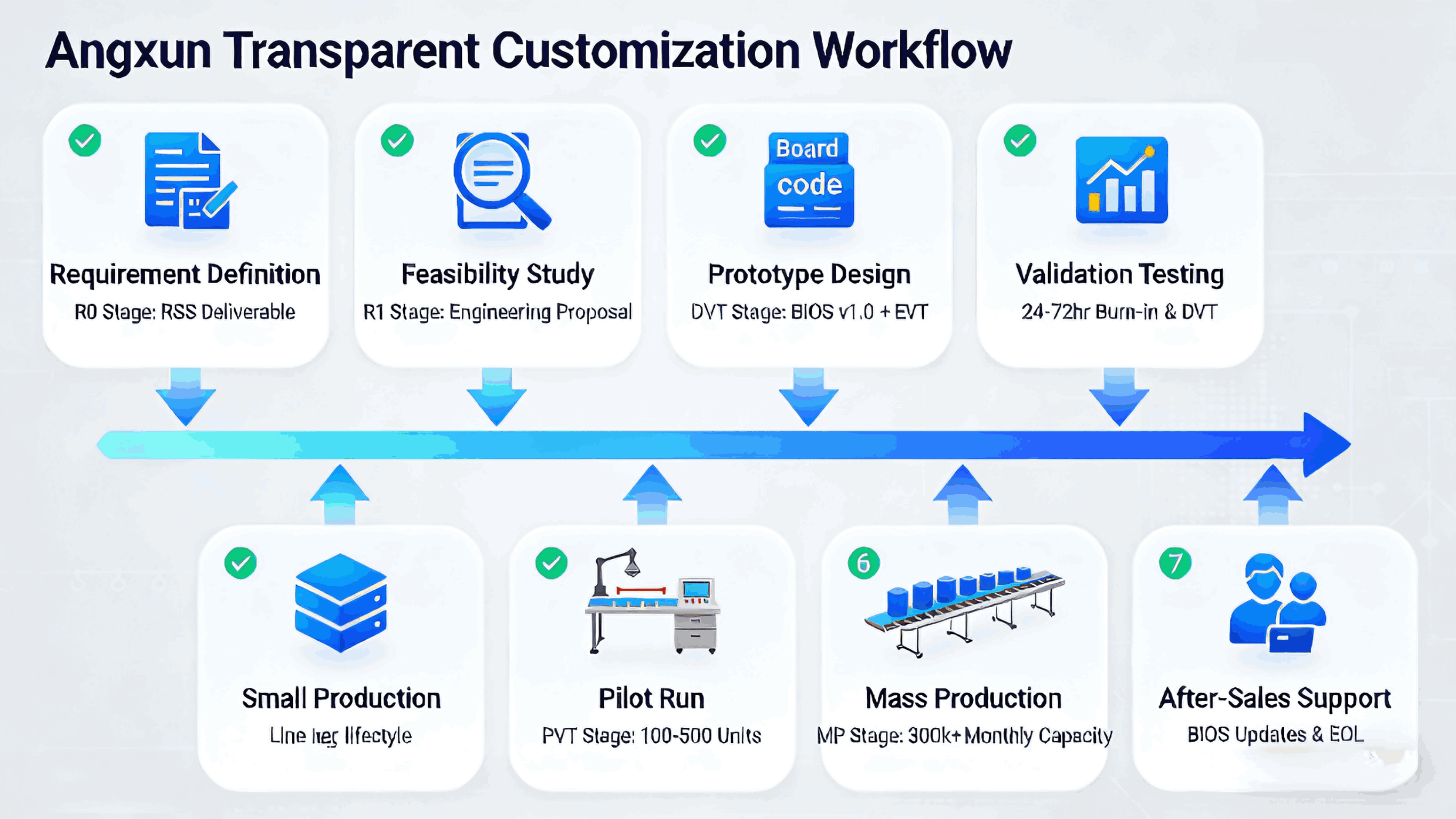

A Fully Transparent Customization Workflow

(A framework designed for OEM/ODM customers, industrial clients, and solution providers.)

Below is the Angxun Customization Flow, engineered to ensure control, predictability, and quality across every step:

1. Requirement Definition (R0 Stage)

We begin with a detailed technical intake session covering:

CPU / chipset requirements

Boot behavior, security policies, and BIOS-level features

I/O mapping and GPIO behavior

Compatibility requirements (memory, storage, PCIe, OS, drivers)

Mechanical constraints and thermal expectations

Certification or regulatory needs

Deliverable: Requirements Specification Sheet (RSS)

Purpose: Eliminates ambiguity from day one.

2. Feasibility Study & Engineering Proposal (R1 Stage)

Angxun’s 50+ R&D engineers evaluate:

Electrical and thermal feasibility

BIOS modifiability

Component availability and EOL status

Potential risks and mitigation options

Time-to-prototype and cost structure

Deliverable: Engineering Feasibility Report + BoM Outline

This phase prevents surprises later in production.

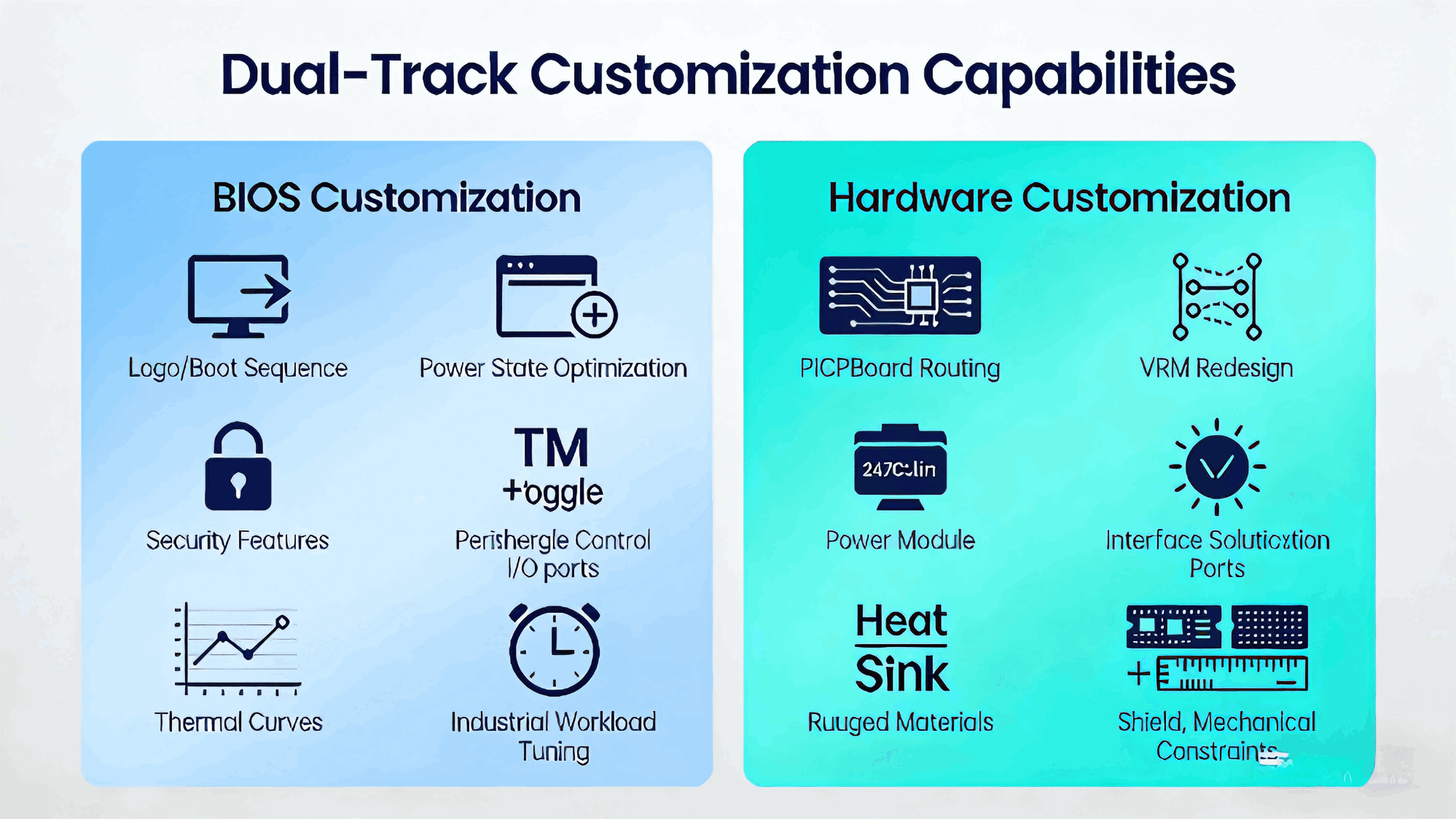

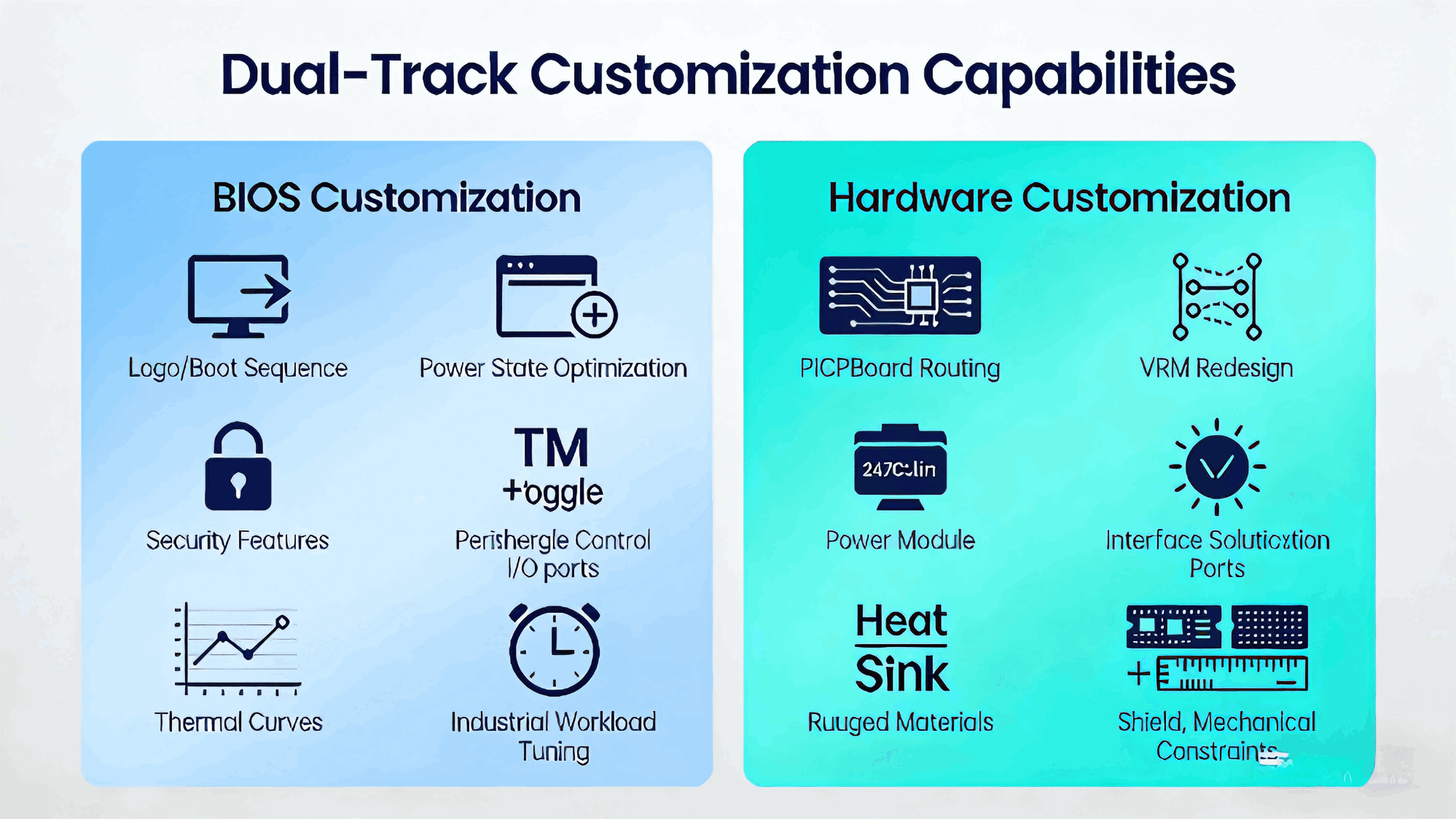

3. Prototype Design & BIOS Customization (DVT Stage)

Our hardware and BIOS engineers start parallel workstreams:

BIOS Customization:

Logo changes, boot sequence adjustments

Power state optimization (S3/S4/S5)

Security features (TPM, Secure Boot, write protection)

Peripheral enable/disable mapping

Custom thermal/fan curves

Industrial or 24/7 workload tuning

Hardware Customization:

PCB re-routing

VRM redesign

Interface/port customization

Thermal solution refinement

Special materials / ruggedization

Deliverables:

4. Validation, Stress Testing & Compatibility Check

This is where many suppliers cut corners—but Angxun does not.

Using our five advanced SMT lines, high-precision SPI, AOI, and reliability equipment, we perform:

Deliverable: DVT Validation Report

Purpose: Ensure the design survives real-world, 24/7 workloads.

5. Pilot Run (PVT Stage)

We initiate a small production batch (100–500 units):

Line setup validation

Material quality verification

BIOS flashing & QC integration

Packaging and labeling tests

Lifetime and repeatability check

Deliverable: PVT Output Report

This stage ensures the design is ready for large-scale production.

6. Mass Production (MP Stage)

With 10,000 m² facility and 300,000+ motherboard monthly capacity, Angxun scales fast and reliably.

Five SMT lines produce consistent output

AOI + SPI ensure traceable quality

BIOS is locked, version-controlled, and archived

Full QC, burn-in, and sampling inspection applied

Deliverable: Mass Production Units + Final Documentation Pack

7. After-Sales Support & Lifecycle Management

Customization doesn't end at shipment.

Angxun provides:

BIOS update maintenance

Long-term component lifecycle management

EOL notifications

Technical support for driver/OS updates

Rapid replacement for critical deployments

This ensures your customized solution remains stable for years, not months.

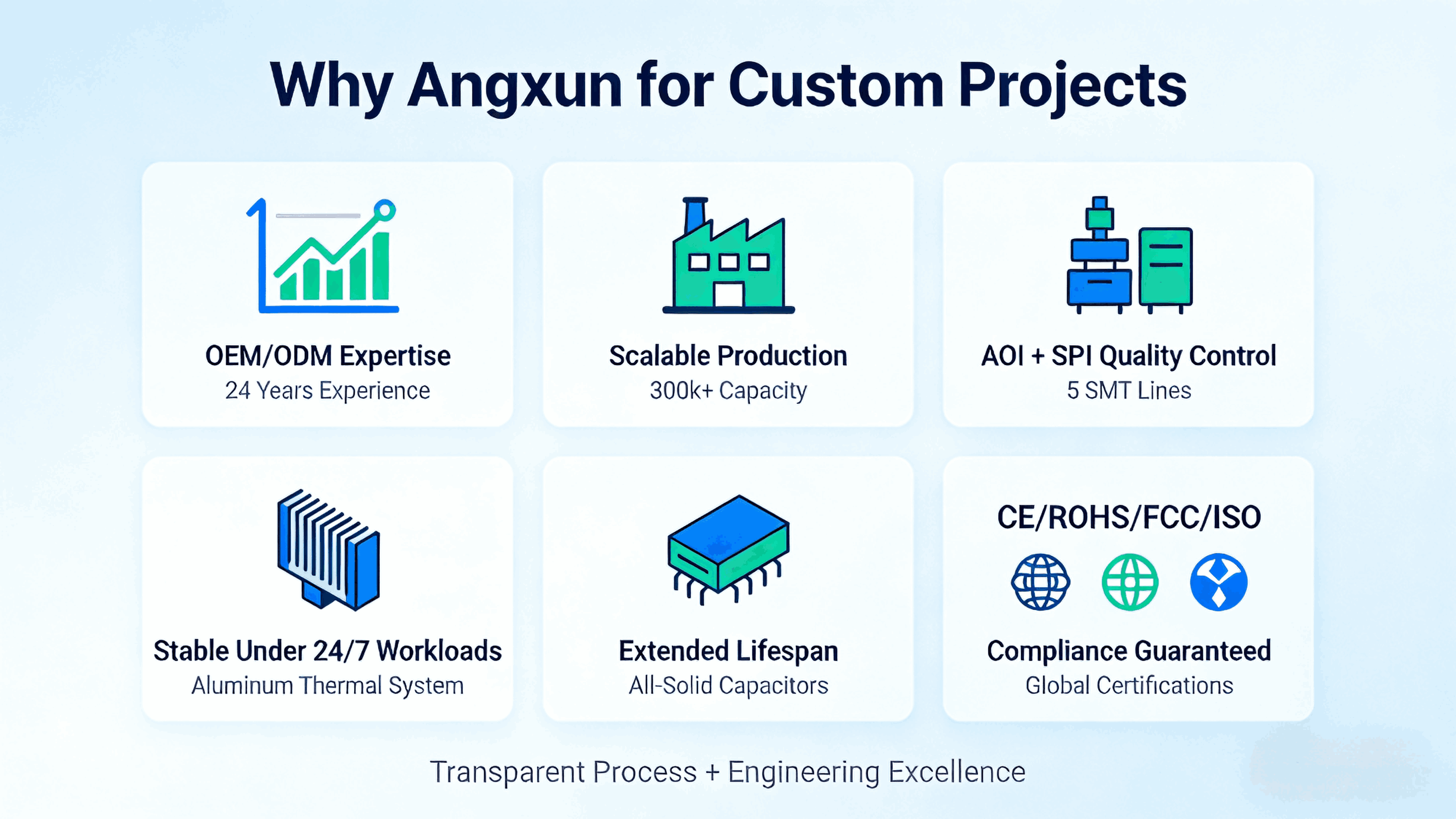

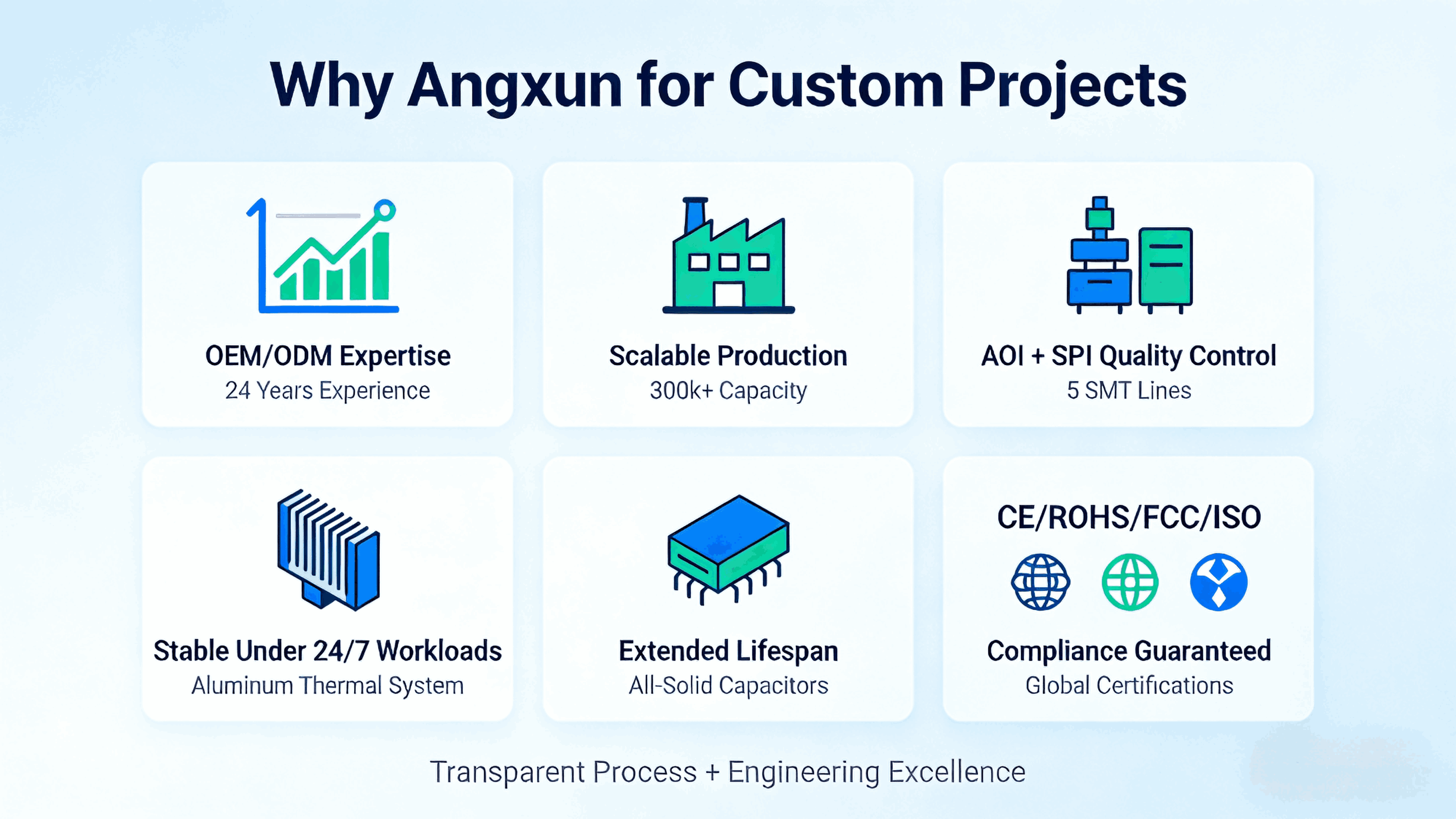

Why Angxun Is Trusted for Custom BIOS & Hardware Projects

Company Strength

24 years OEM/ODM experience

10,000 m² factory & 500+ staff

300,000+ motherboard monthly capacity

5 advanced SMT lines

Eco-environment certified materials

CE / RoHS / FCC / ISO certifications

Product Engineering Advantages

Aluminum-based thermal cooling system

All-solid capacitors for long lifespan

PCB copper plating technology

Independent CPU power supply

Zero-burning protection circuit

Dual safety voltage/current stabilizers

These engineering features directly improve reliability for custom solutions.

Customization Should Not Be a Black Box—It Should Be a Competitive Advantage

A transparent process eliminates fear.

<p line="Kq38" class="ql-direction-ltr ql-long-96991899" ql-global-para="true" linespacing="150" style