Why data-driven refresh planning leads to lower costs, higher stability, and predictable procurement cycles.

For most IT and infrastructure leaders, hardware refresh is no longer just a budgeting event—it is a strategic decision that directly affects operational continuity, total cost of ownership (TCO), and long-term innovation capacity.

Yet many organizations still refresh hardware only when failures accumulate or performance becomes unacceptable. This reactive model is costly.

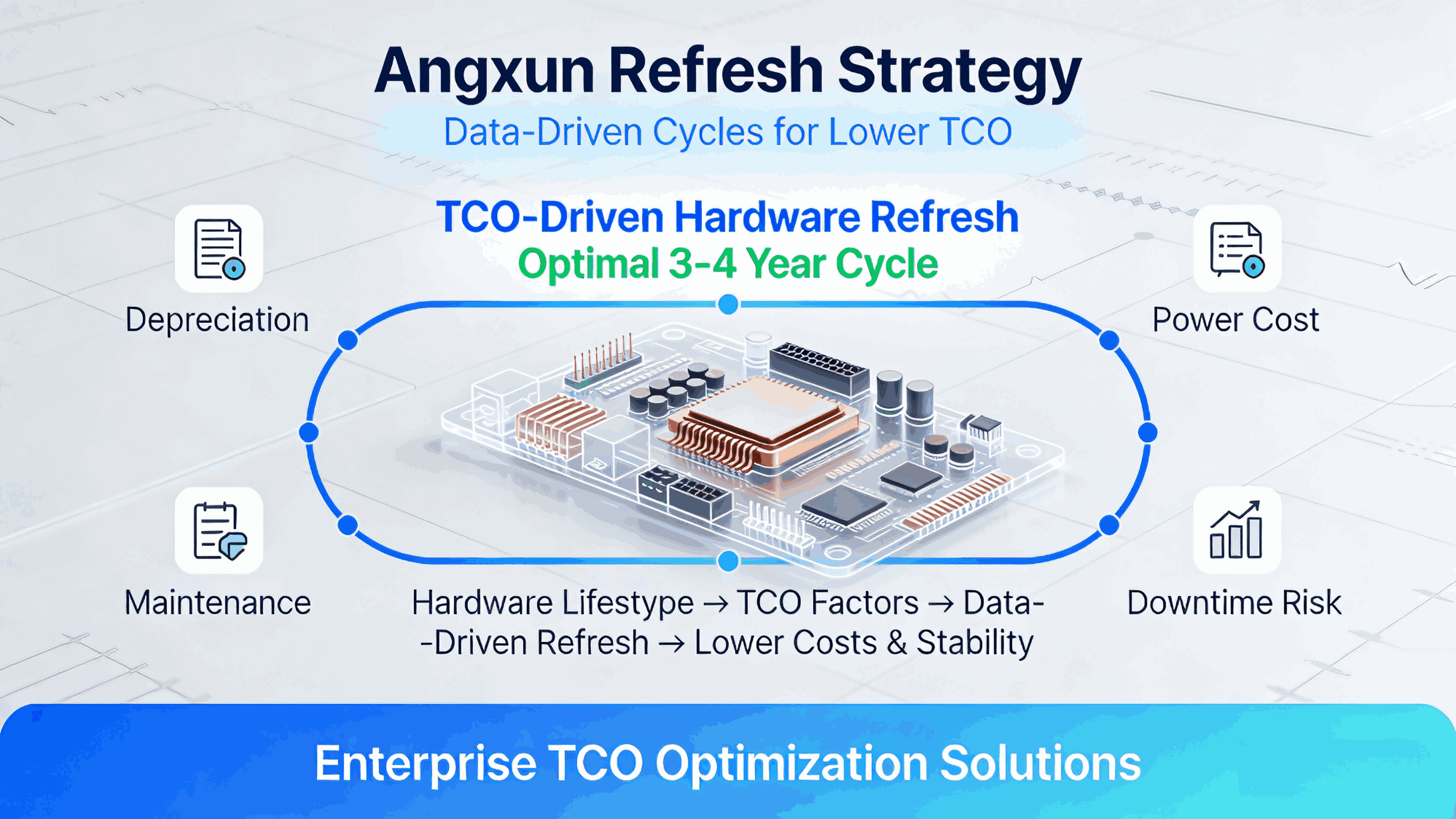

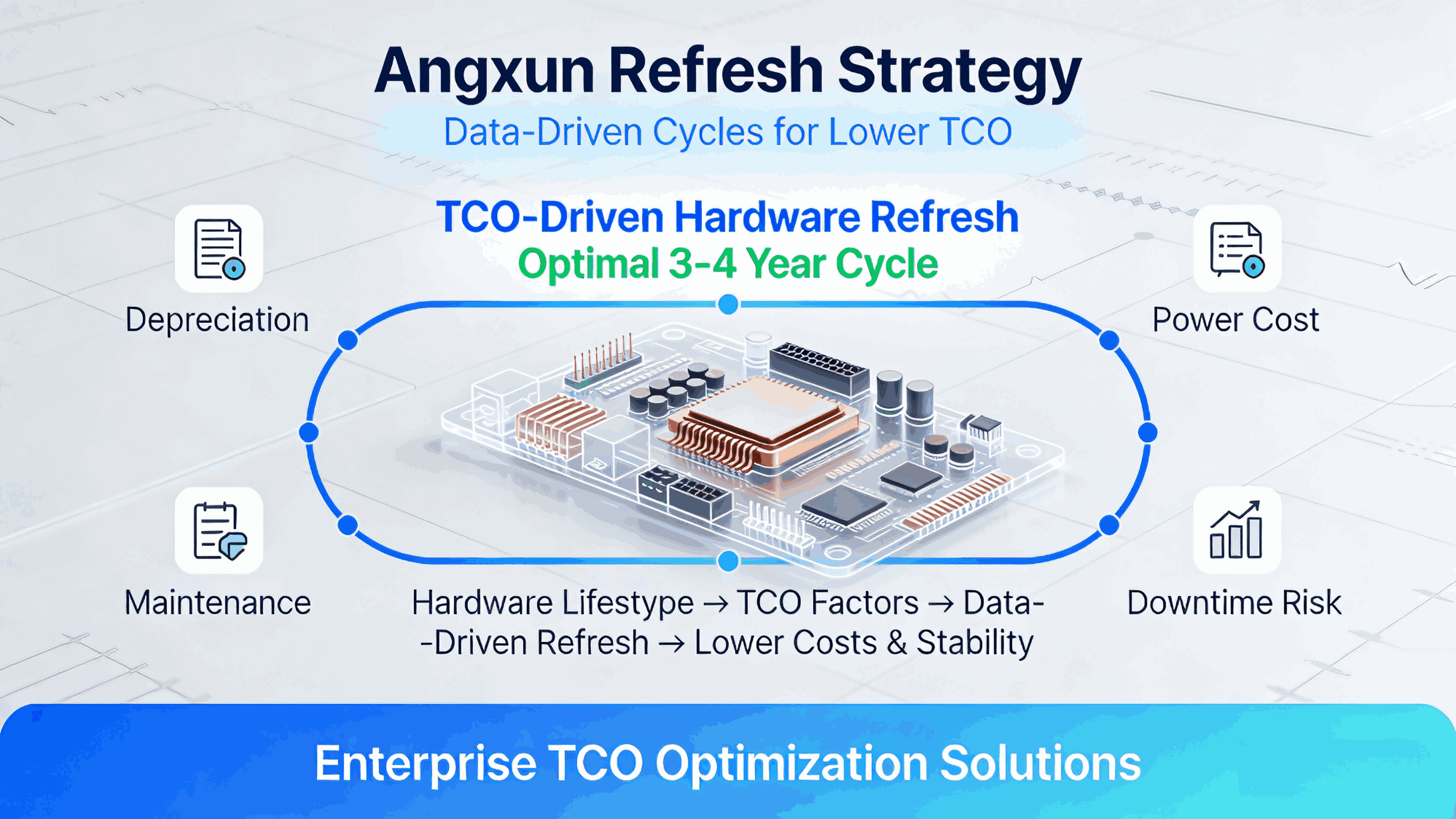

A data-driven refresh cycle—grounded in power efficiency, component aging curves, performance-per-watt improvements, and maintenance overhead—allows enterprises to optimize both performance and profitability.

Why Hardware Refresh Timing Matters More Than Ever

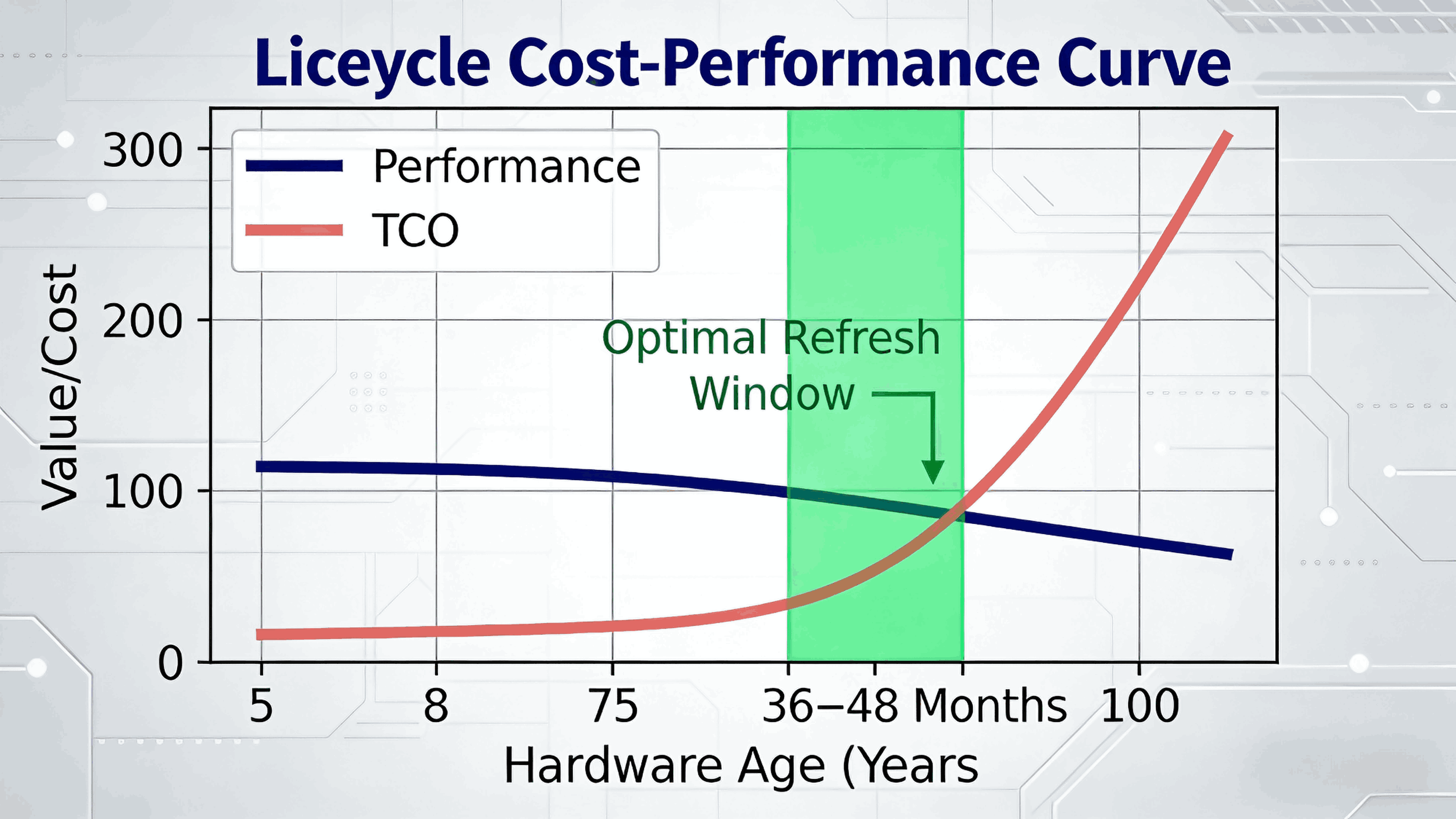

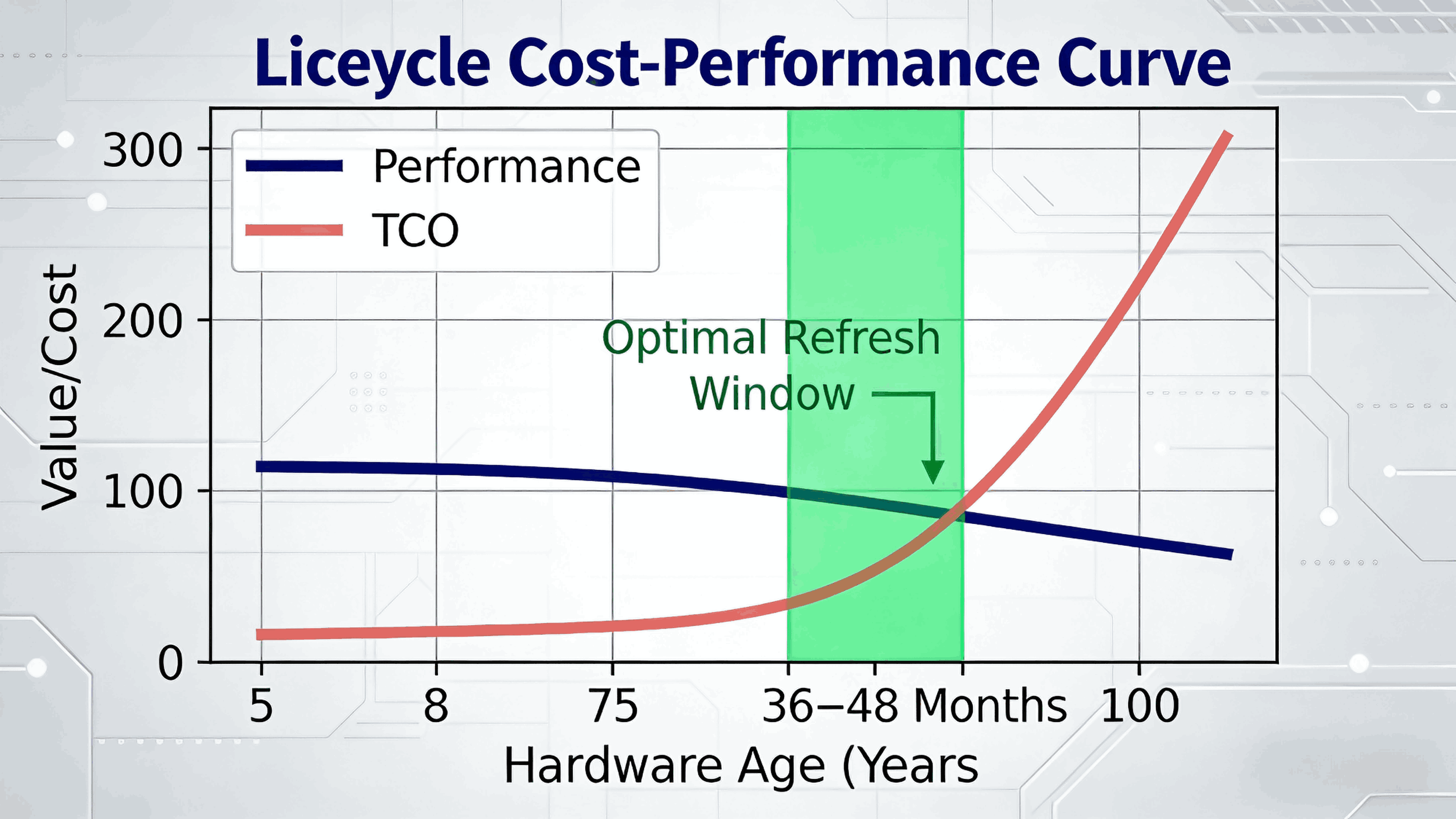

Across data centers, edge deployments, industrial automation and enterprise workstations, hardware follows a predictable lifecycle:

Years 0–1: Peak performance, lowest failure rate

Years 2–3: Gradual efficiency decline; firmware-related incompatibilities increase

Years 3–5: Power consumption rises; component aging accelerates

After Year 5: Maintenance cost spikes; downtime risk increases non-linearly

From a TCO perspective, the “cost curve” typically crosses the “performance curve” between 36 and 48 months, making it the economically optimal upgrade window for most organizations.

A Simple TCO-Based Model for Determining the Best Refresh Point

Below is a practical model enterprises can apply:

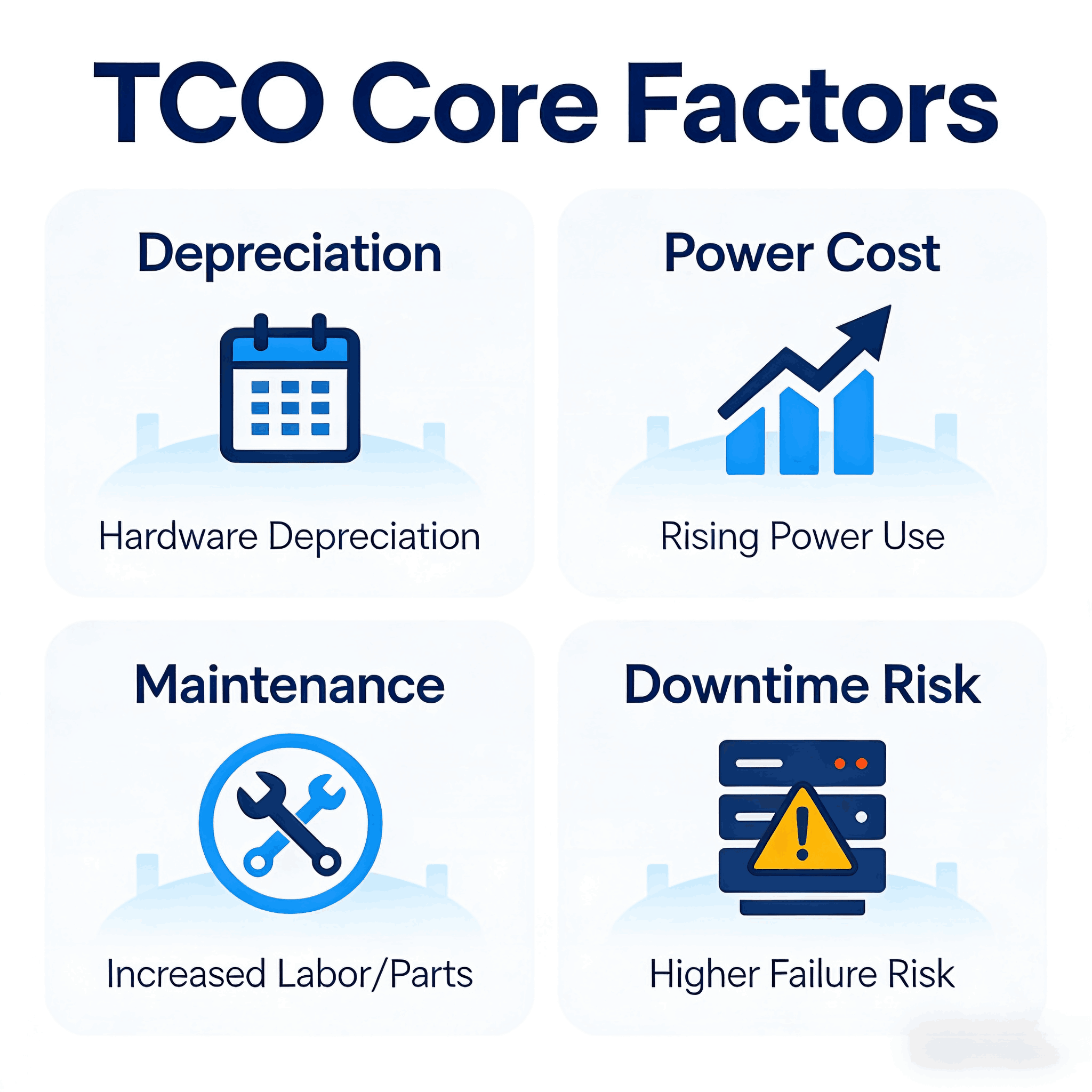

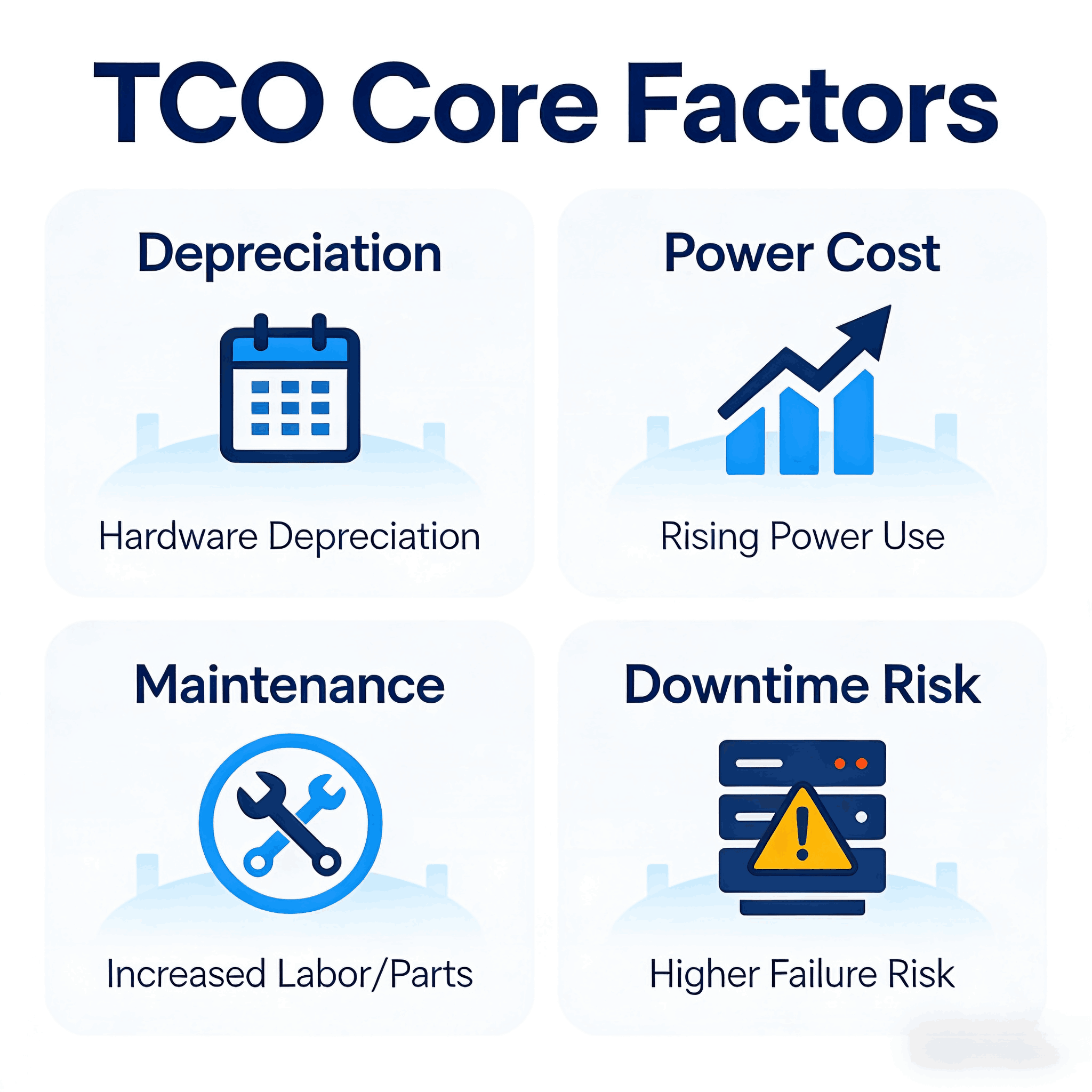

TCO(t) = Depreciation + Power Cost + Maintenance + Downtime Risk Cost

Where:

Depreciation: Hardware’s annualized cost over its intended lifecycle.

Power Cost: Older hardware consumes 15–30% more power after year three due to component wear.

Maintenance Cost: Spare parts availability declines, labor hours increase, and firmware issues become more common.

Downtime Risk Cost: Even a 0.5–1% annual increase in failure probability significantly impacts mission-critical workloads.

Using this formula, we typically see:

Year 1–2: Low TCO, high performance

Year 3–4: TCO begins rising; failure rates trend upward

Year 4–5: TCO accelerates sharply—suboptimal for most enterprises

Conclusion:

Most organizations maximize ROI by refreshing within 3–4 years, or earlier in high-density or 24/7 environments.

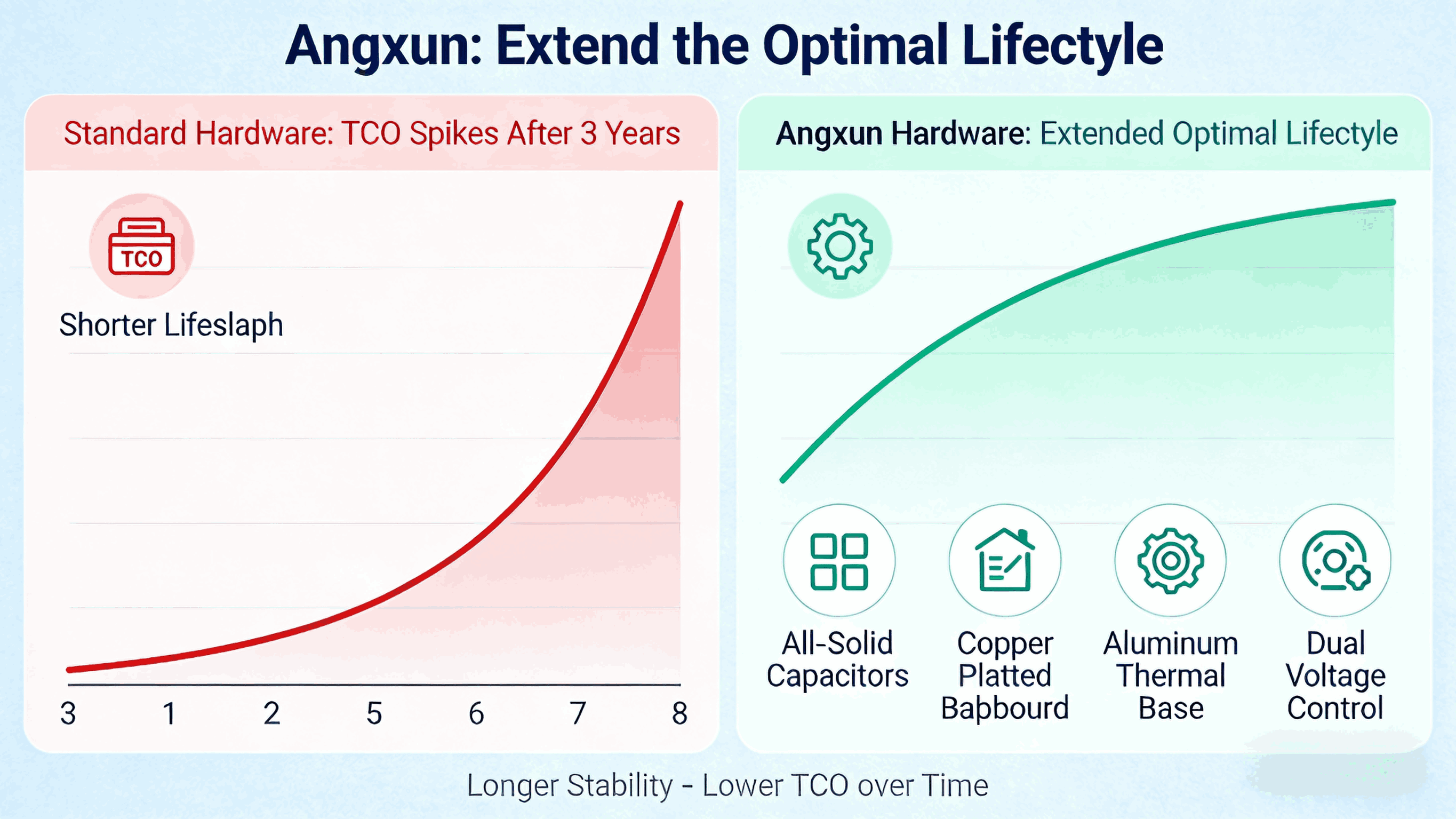

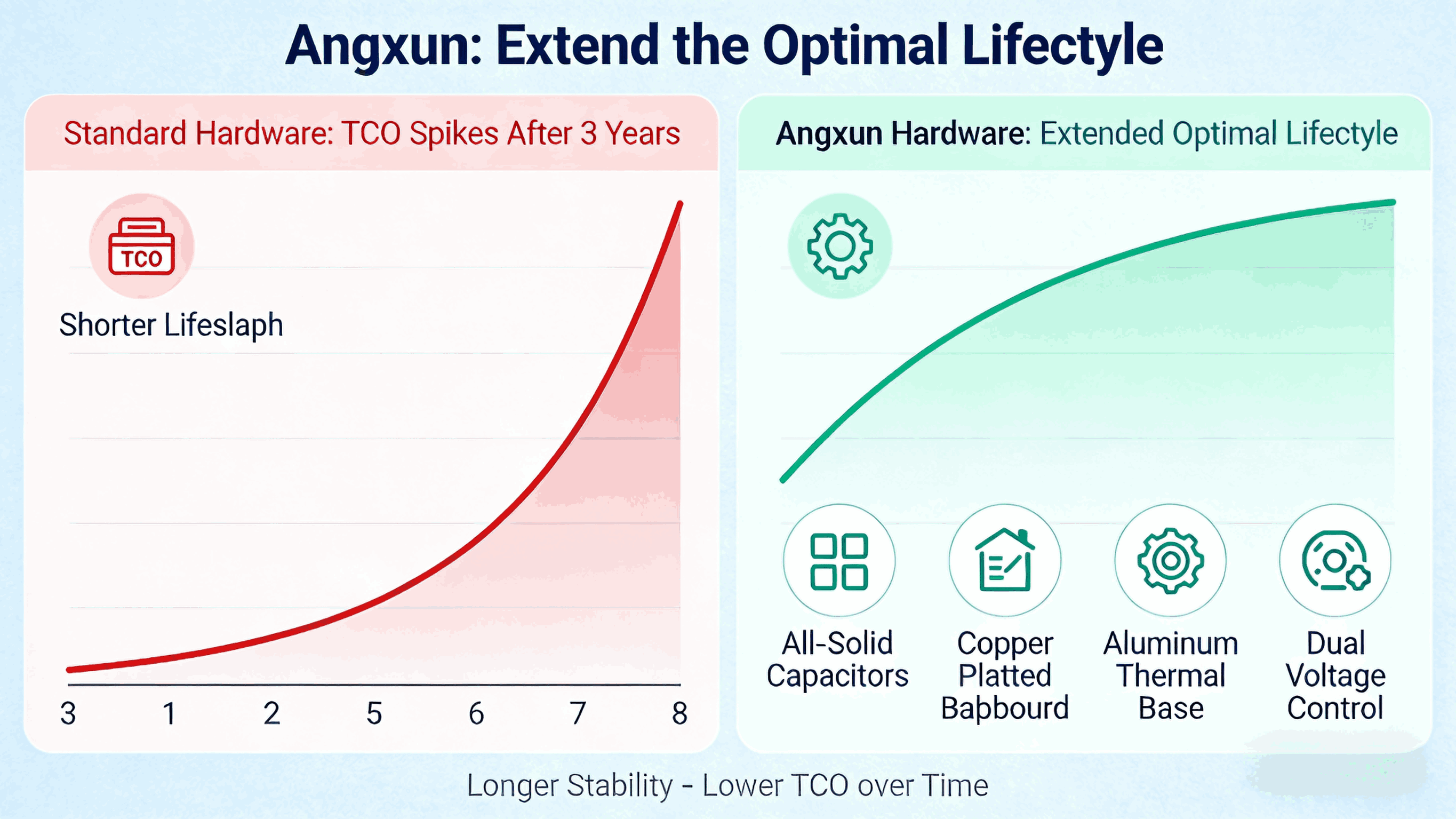

How High-Efficiency, Long-Lifecycle Hardware Changes the Model

This is where hardware engineering matters.

Motherboards and platforms designed with high thermal efficiency, premium capacitors, robust PCB copper plating, and multi-layer power protection significantly slow down aging curves—effectively extending the optimal refresh cycle.

At Shenzhen Angxun Technology Co., Ltd., engineering for longevity and stability is not a feature—it is a design philosophy. Our products integrate:

Core Product Advantages

Advanced aluminum-base cooling system for stable thermals

All-solid capacitors for long-term voltage integrity

Thick copper PCB plating for superior signal and power stability

Independent CPU power supply design

Zero-burn protection circuitry

Dual safety voltage/current stabilization modules

These design principles reduce performance degradation over time and keep TCO low throughout the lifecycle.

Why Angxun’s Engineering Approach Builds a Better TCO Curve

✔ Longer effective lifecycle

Failure rate remains flatter in years 3–5.

✔ Lower operational power cost

Optimized VRM and efficiency-first board design reduce cumulative power draw.

✔ Lower maintenance overhead

Quality Bill of Materials (BOM) and robust PCB architecture minimize component aging issues.

✔ Predictable, repeatable hardware performance

Critical for enterprise, industrial, and OEM deployments.

Backed by a Scalable, Experienced Manufacturing Platform

With 24 years of OEM/ODM experience, Angxun operates a 10,000 m² facility equipped with:

5 advanced SMT production lines

High-precision SPI, AOI and automated inspection

Monthly output capacity of 300,000+ industrial/PC motherboards

A team of 50+ R&D engineers

Compliance with CE, RoHS, FCC, ISO certifications

Eco-friendly manufacturing materials

Fast delivery and guaranteed after-sales support

This ensures that enterprises receive hardware designed not just for performance—but for longevity and predictable refresh cycles.

How to Implement a Refresh Strategy in Your Organization

Use this checklist:

1. Map current hardware by age and workload criticality

Identify which systems impact revenue, operations or uptime.

2. Calculate TCO per device using the 4-factor model

Depreciation + Power + Maintenance + Downtime Risk.

3. Identify refresh candidates when TCO exceeds 80–90% of new hardware cost

4. Standardize a 36–48 month refresh cycle

Adjust based on workload intensity.

5. Choose hardware engineered for low TCO and long lifecycle

This directly reshapes your cost curve.

Conclusion: Regular Refresh is Not a Cost—It’s a Cost-Control Strategy

Organizations that refresh hardware proactively achieve:

And with high-efficiency, long-lifecycle engineering, the economic benefits compound over time.

If your organization wants to redesign its refresh strategy—or evaluate hardware platforms optimized for long-term TCO—Angxun is ready to support you with engineering expertise and enterprise-grade manufacturing capability.