At Shenzhen Angxun Technology, our Field Application Engineers (FAEs) are the backbone of our service. With 24 years of OEM/ODM experience, a 10,000 m² modern factory, 5 SMT lines, and a 50+ member R&D team, we not only build reliable Intel/AMD motherboards and Mini PCs—we also ensure every integrator receives engineering-level support throughout the project lifecycle.

In this interview-style article, our Chief FAE shares five of the most challenging real-world cases we solved in the past year. These stories demonstrate the technical depth, responsiveness, and value that integrators rely on.

Q1: A Digital Signage Client Reported Random Black Screens Across 80 Sites. What Did You Discover?

FAE Answer:

This was an urgent case—about 10% of players randomly went black after running for several hours. The client initially suspected a GPU failure.

After remote diagnostics and log analysis, we discovered that:

The displays used custom EDID data

Their CMS software forced refresh rates unsupported by specific panels

In some units, HDMI cable impedance was inconsistent

We solved the issue by:

Providing a custom BIOS EDID override profile

Adding a watchdog-based display recovery mechanism

Recommending shielded HDMI cables validated in our lab

No hardware replacement was needed.

This saved the customer significant on-site maintenance costs and prevented large-scale screen downtime.

Q2: A Security Integrator Had a CPU Thermal Throttling Issue Even in an Air-Conditioned Room. How Was It Resolved?

FAE Answer:

This deployment used 10th-gen Intel CPUs in a compact chassis. Thermal throttling began once the system hit 75–80% sustained CPU load.

Our analysis showed:

Heat was accumulating on VRM components

Airflow inside the customer’s chassis was insufficient

Their existing cooler didn’t fully cover the heat path

Because Angxun motherboards use:

We optimized the thermal solution by:

Result: CPU stayed below 65°C under full load, and the integrator avoided expensive chassis changes.

Q3: Why Was a Windows-Based Kiosk Taking 90 Seconds to Boot?

FAE Answer:

The customer suspected BIOS or motherboard issues, but after our investigation:

Their OS image loaded unnecessary drivers

Their SSD had inconsistent firmware

TPM initialization delayed boot by 12 seconds

We fixed the issue by:

Customizing BIOS to skip non-essential checks

Flashing SSDs with uniform firmware

Creating a clean, kiosk-optimized Windows image

Boot time dropped from 90 seconds to 21 seconds, dramatically improving kiosk user experience.

Q4: An Industrial Automation Client Needed Legacy RS-232 Timing Accuracy for a 20-Year-Old Machine. How Did You Achieve It?

FAE Answer:

Legacy equipment often has extremely sensitive timing requirements, especially for serial communication.

Their issue:

Because Angxun specializes in industrial motherboards, we implemented:

A custom BIOS option for fixed legacy UART clocking

A stability patch for their Linux kernel driver

A thermal compensation algorithm for extended environments

After validation in our stress chamber (40°C–85°C), the solution passed 72-hour nonstop testing.

The customer later standardized Angxun boards for all future factory expansions.

Q5: A Retail Integrator Needed a Mini PC With 3 Displays—but Their Software Required Mixed Drivers. How Did You Make It Work?

FAE Answer:

Their system needed:

Two digital signage screens

One touchscreen for staff

A combination of Intel iGPU + discrete GPU drivers

Driver conflicts caused display initialization failures.

Our solution included:

Providing a customized BIOS with PCIe lane remapping

Engineering a hybrid driver package validated by our R&D team

Running a 48-hour multi-display burn-in on our AOI-certified test line

The result was a stable triple-display system that has been deployed across more than 600 stores to date.

Why These Cases Matter to System Integrators

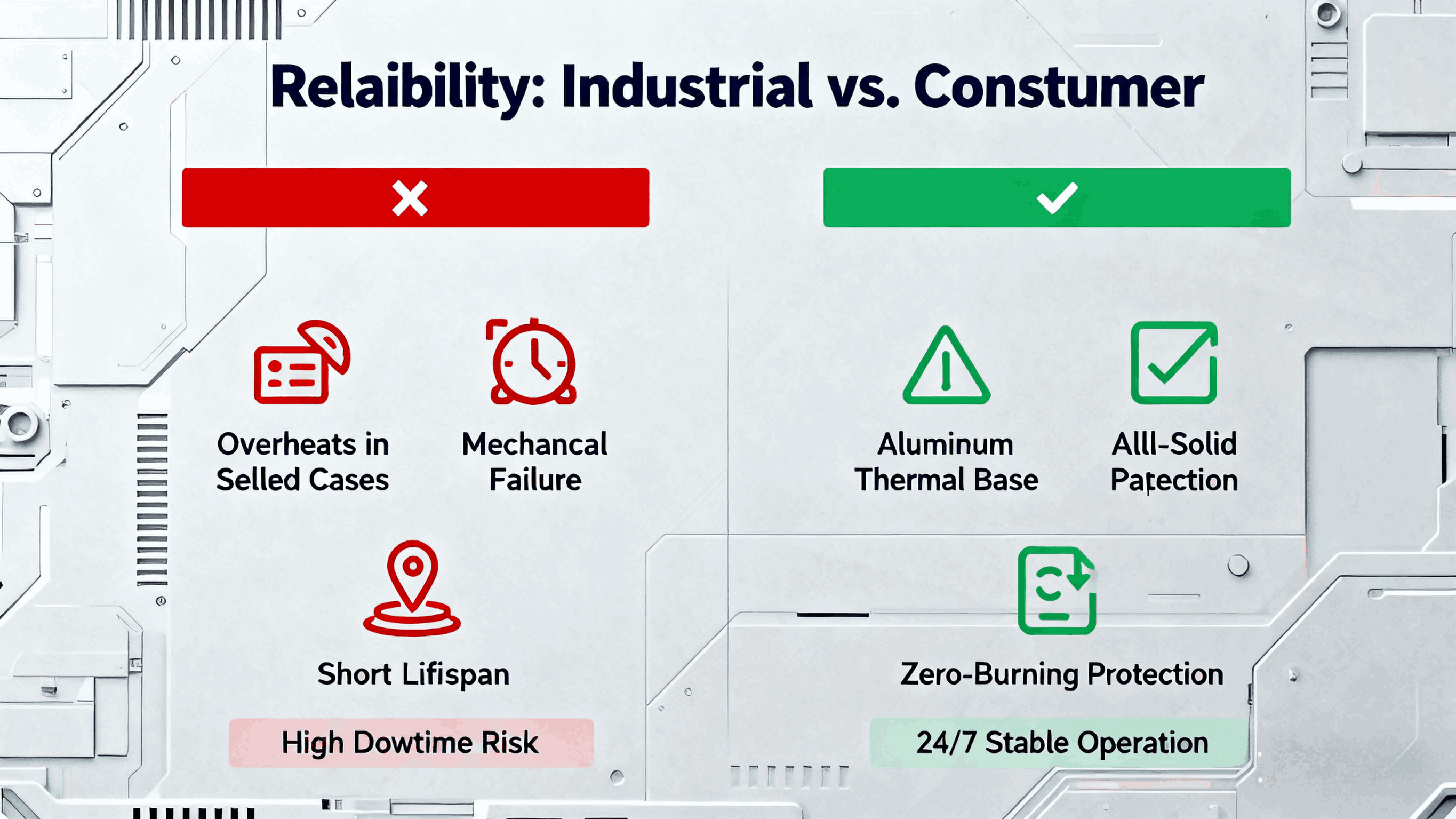

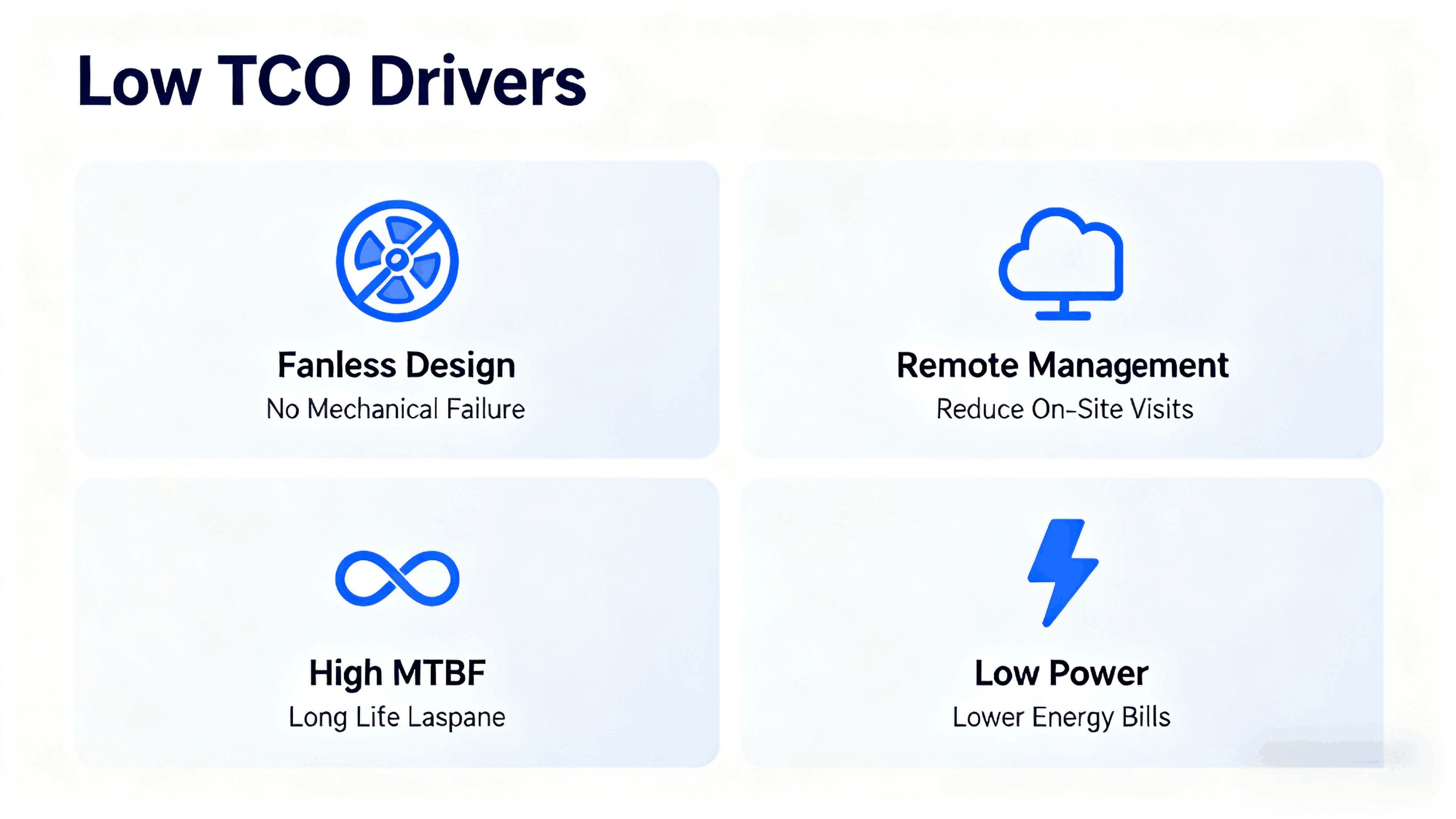

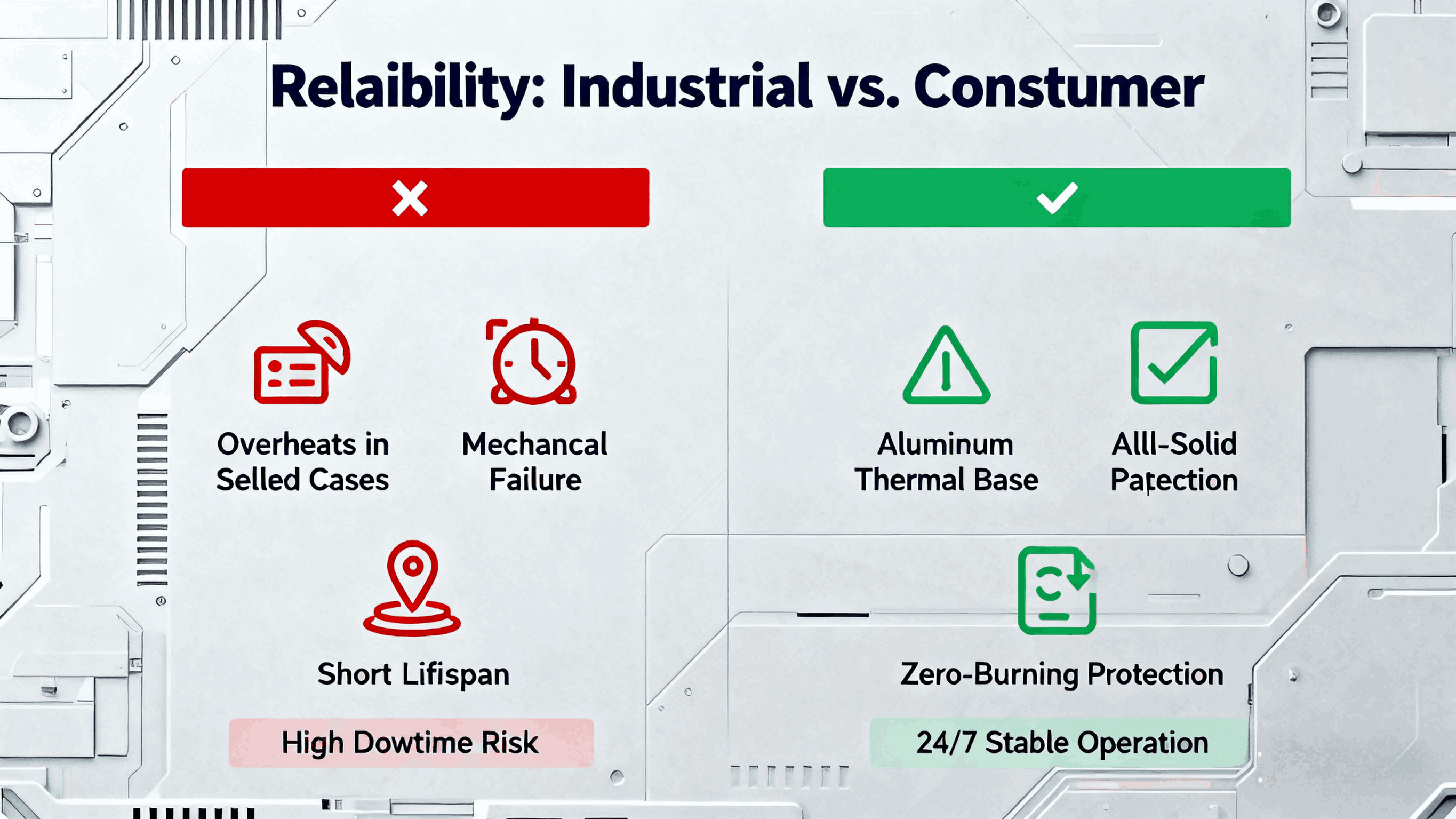

Each case represents a real-world engineering challenge where hardware, firmware, software, and environmental factors intersect. These outcomes are only possible because Angxun offers:

Engineering Advantages

High-reliability motherboards with industrial-grade components

PCB copper plating for signal integrity

Independent CPU power supply design

Zero-burning protection circuits

Dual-safety voltage/current stabilization

Manufacturing Advantages

5 SMT lines with SPI + AOI precision testing

300,000+ monthly motherboard capacity

Strict BOM control for long-term supply stability

CE, FCC, ROHS, ISO certifications

Service Advantages

24 years of OEM/ODM expertise

50+ R&D engineers

Rapid BIOS, firmware, and driver customization

Guaranteed after-sales technical support

For integrators deploying mission-critical hardware, these capabilities translate into lower project risk, faster issue resolution, and stable long-term operation.

Conclusion: Real Engineering Support Makes a Real Difference

Behind every successful deployment is a strong technical support team. These five cases highlight how Angxun’s FAEs—backed by robust R&D, advanced manufacturing, and deep industry experience—help integrators overcome the toughest challenges in the field.

If your team needs engineering-level guidance, custom firmware, long-term supply assurance, or troubleshooting support, our technical department is ready to assist.