In today’s fast-moving hardware market, product success is no longer defined only by performance or cost—it is defined by speed.

The brands, integrators, and solution providers that win are the ones who can turn a concept into a finished, retail-ready product faster than their competitors.

But achieving that kind of speed is only possible with a manufacturing partner that knows how to build a seamless, end-to-end productization pipeline.

At Shenzhen Angxun Technology, we’ve spent the past 24 years refining this process—combining engineering expertise, rapid prototyping, and high-volume manufacturing into one synchronized workflow.

Here’s what that pipeline looks like.

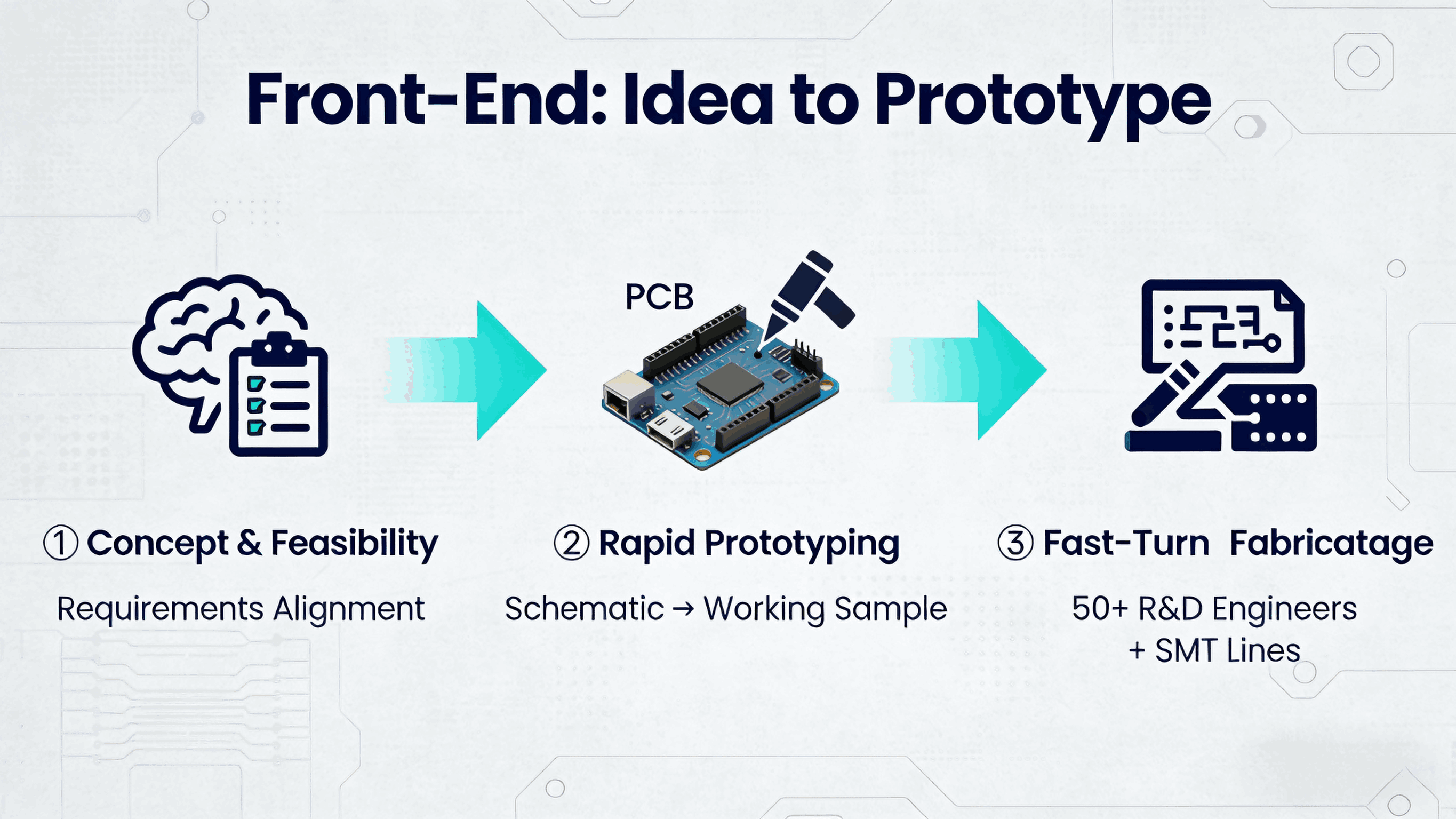

1. Concept to Feasibility: Turning Ideas Into Actionable Engineering Plans

Every fast product launch starts with clarity.

Our engineering and FAE teams work directly with integrators and OEMs to define:

Hardware requirements

Performance targets

Environmental and reliability needs

Application-specific constraints

BOM cost expectations

Long-term supply strategies

With a 50+ R&D engineering team and two decades of motherboard, Mini PC, and industrial platform design experience, we can quickly match the right Intel/AMD architecture and component ecosystem.

This early-stage alignment is the foundation of accelerated productization.

2. Rapid Prototyping: From Schematic to Working Sample in Record Time

For white-label hardware to succeed, prototyping must be fast—but precise.

Angxun’s five SMT lines, SPI/AOI automated inspection, and a 10,000 m² factory floor allow us to build and refine prototype batches at speed while maintaining quality.

Our prototype advantages include:

Quick-turn PCB fabrication

All-solid capacitors and copper-plated PCB tech

Independent CPU power supply design

Zero-burning protection circuitry

Superior thermal solutions with aluminum baseplates

The result: functional samples delivered in days—not weeks.

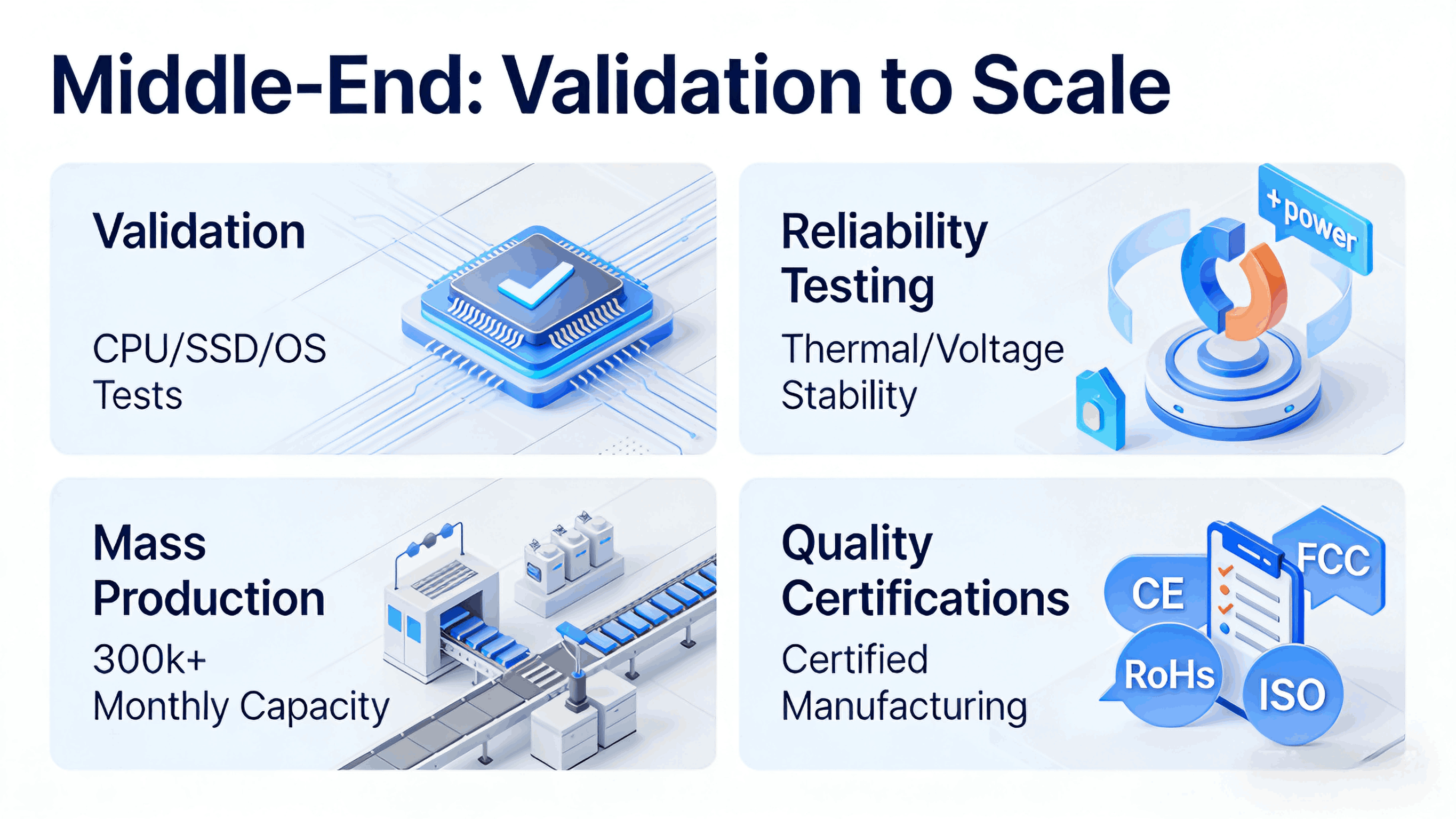

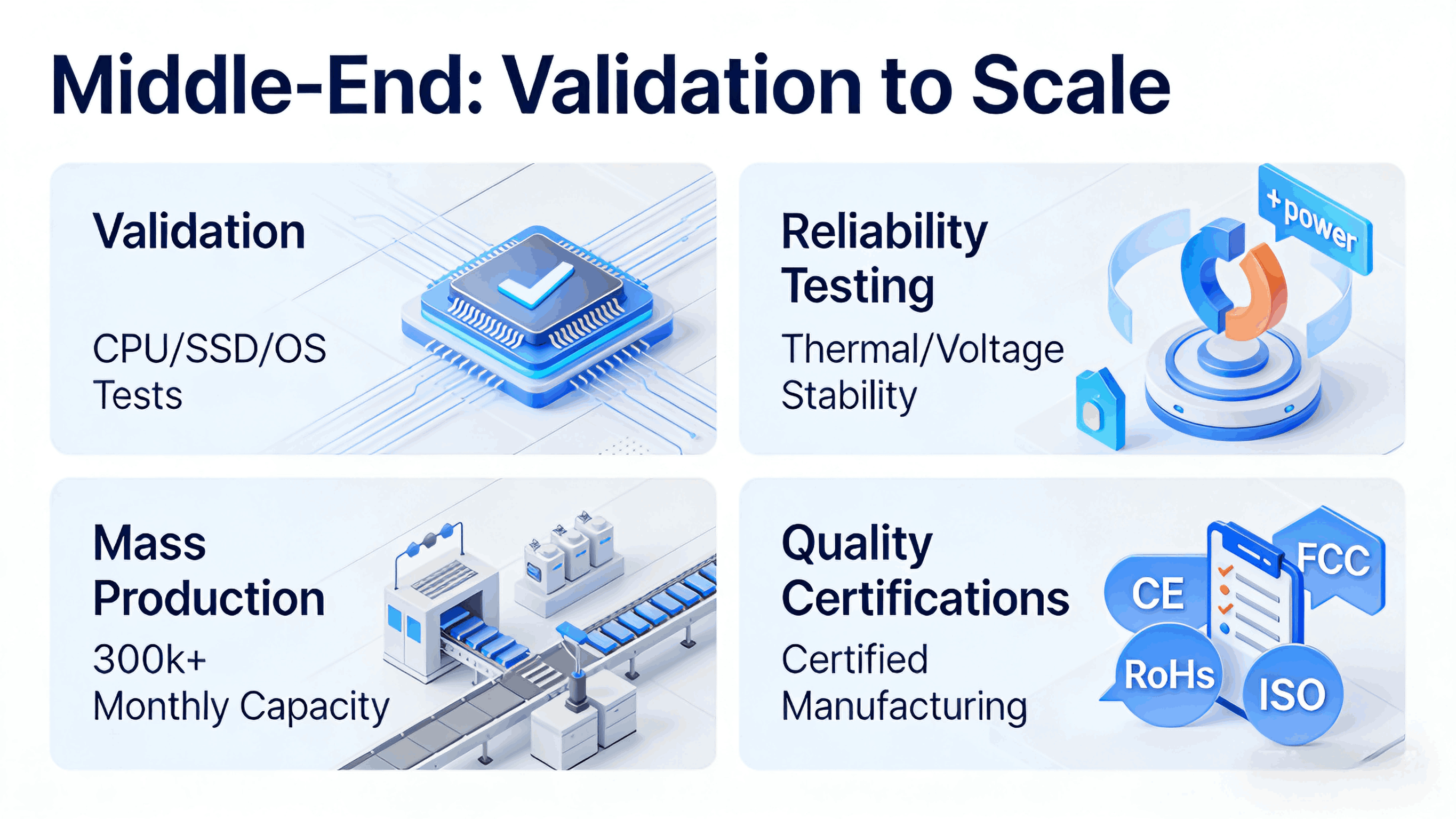

3. Compatibility & Reliability Validation: Eliminating Surprises Before Mass Production

Before a platform is approved for scaling, our engineers perform deep validation across:

CPU / memory / SSD / NIC / GPU compatibility

Power stability and voltage protection

Thermal management efficiency

OS and driver integration

Long-duration load testing

With a motherboard production capacity of 300,000 units per month, quality and repeatability are non-negotiable.

This validation stage ensures integrators never encounter:

Unexpected BIOS issues

Random component conflicts

Thermal throttling surprises

Field failures after deployment

Every build is engineered to be predictable and deployment-ready.

4. Mass Production: Industrial-Grade Scale, White-Label Flexibility

Once a design passes verification, the transition to full production is seamless.

Our manufacturing advantages include:

CE, ROHS, FCC, ISO-certified factory

Eco-friendly materials

500+ trained staff

Automated assembly and testing

Real-time production reporting

Customizable packaging and branding options

We support:

OEM motherboard production

Industrial PC and Mini PC builds

Custom I/O layouts

Custom chassis, thermal, BIOS, and firmware

White-label branding and accessory kits

The entire pipeline is designed to integrate with your sales and channel timelines.

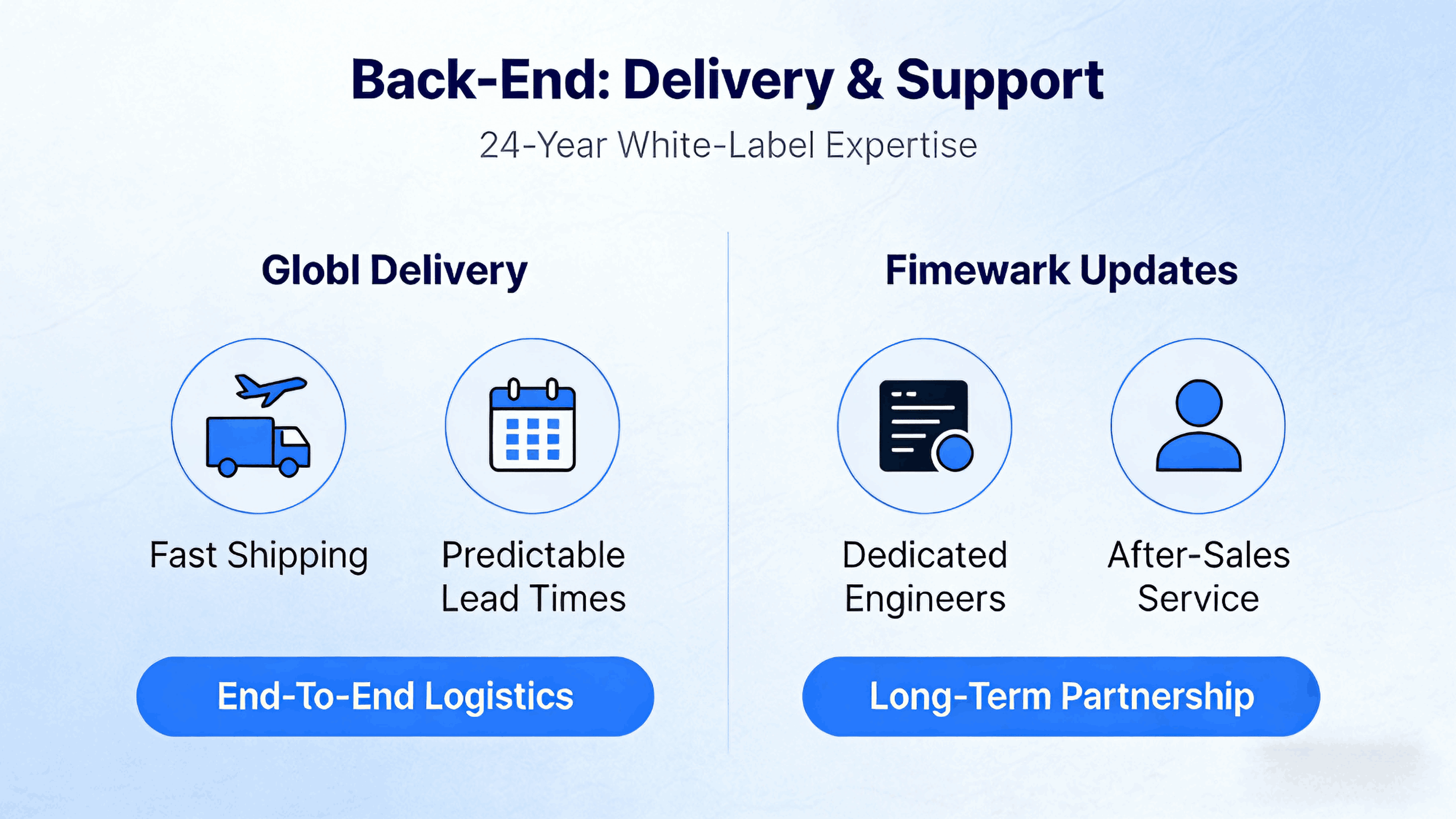

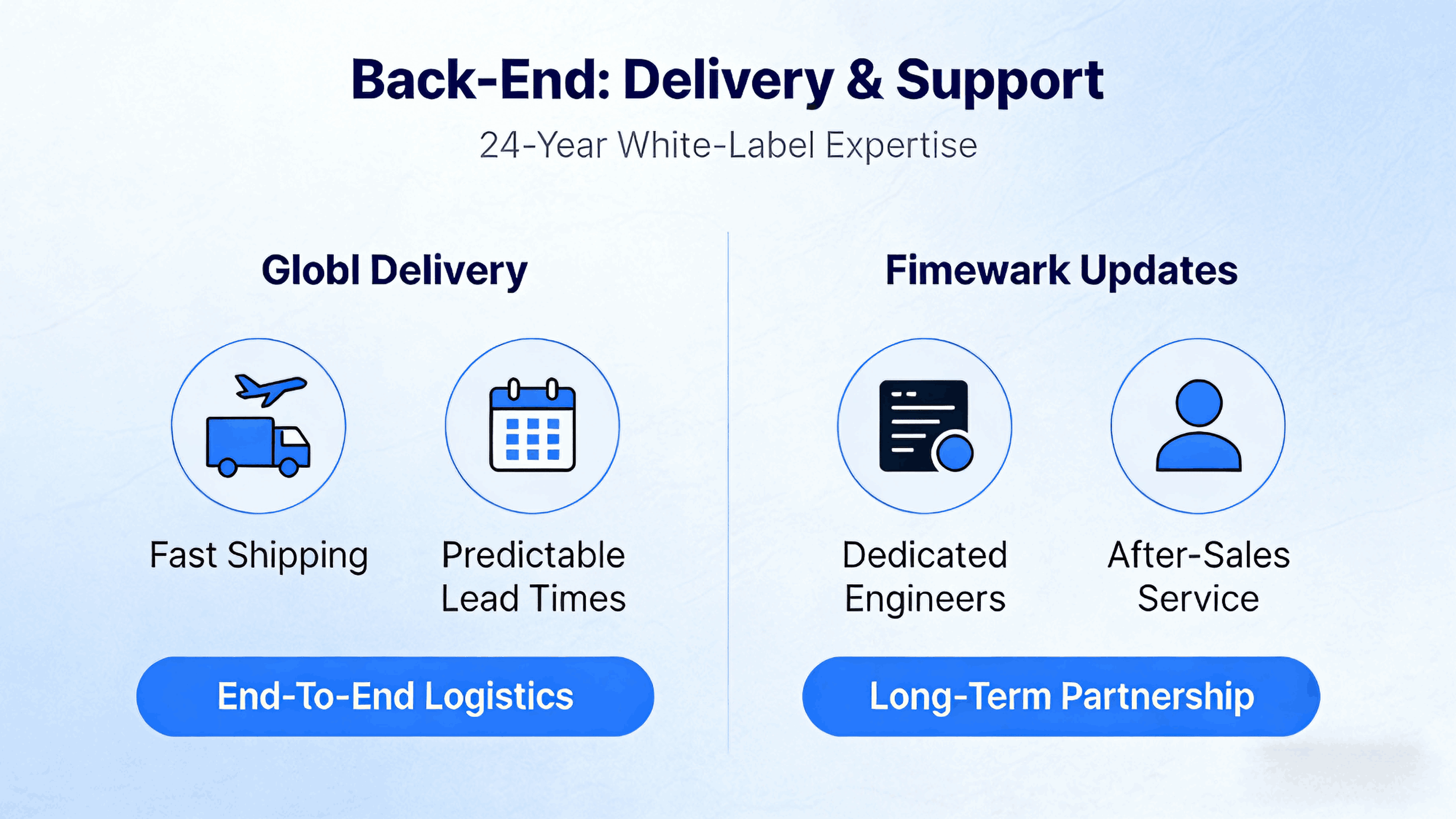

5. Fast Delivery, Global Shipping, and Lifecycle Support

Speed doesn’t end at the production line.

Our logistics and after-sales system ensures:

Fast order-to-ship cycles

Predictable lead times

Long-term availability of key components

Dedicated support engineers

Firmware/BIOS maintenance

Guaranteed after-sales service

This makes Angxun an ideal partner for:

System integrators

Brands building new product lines

Retail-focused device makers

SaaS/PaaS companies deploying hardware

Industrial and vertical-market solution providers

Efficiency Is Not Just a Goal—It’s a Co-Created Advantage

The real value of a white-label partnership isn’t just manufacturing.

It’s the ability to co-create efficiency, eliminate bottlenecks, and launch products at a pace that keeps you ahead of the market.

At Angxun, our commitment is simple:

From the moment you place an order to the moment your product reaches the shelf—we make every step faster, smoother, and more reliable.

If you’re building your next motherboard, Mini PC, or vertical-specific hardware product, we’re ready to accelerate your roadmap.want.