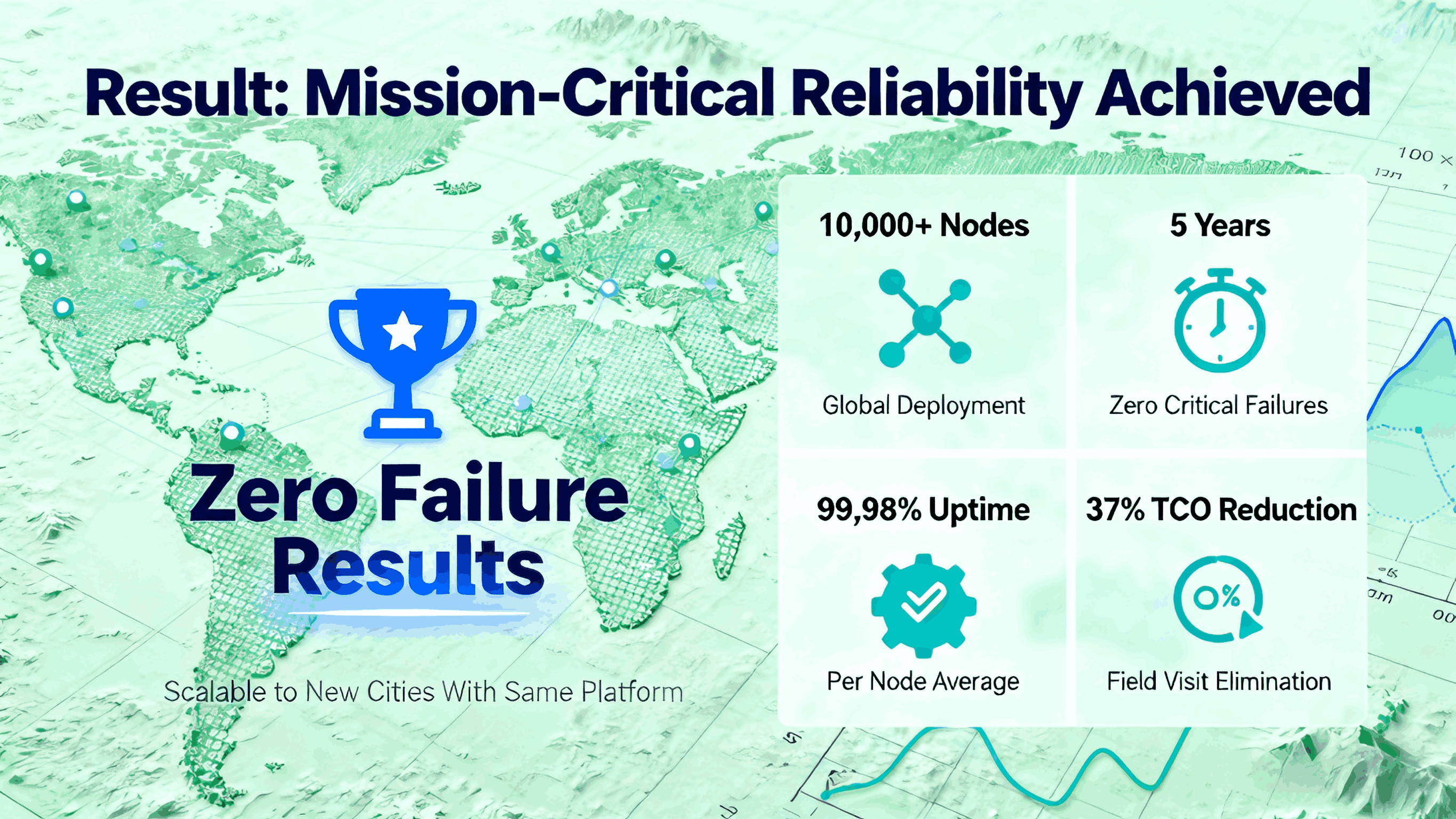

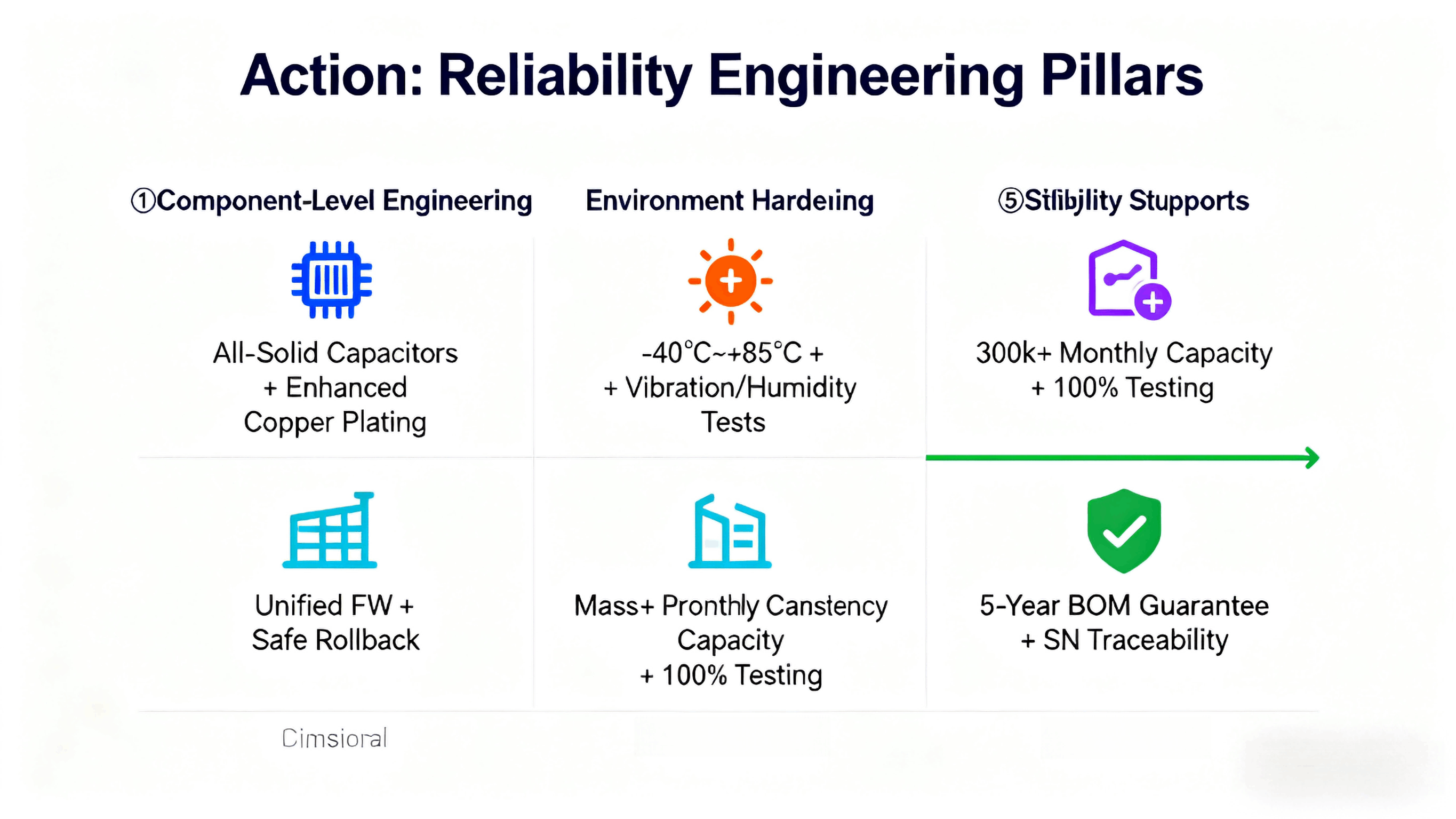

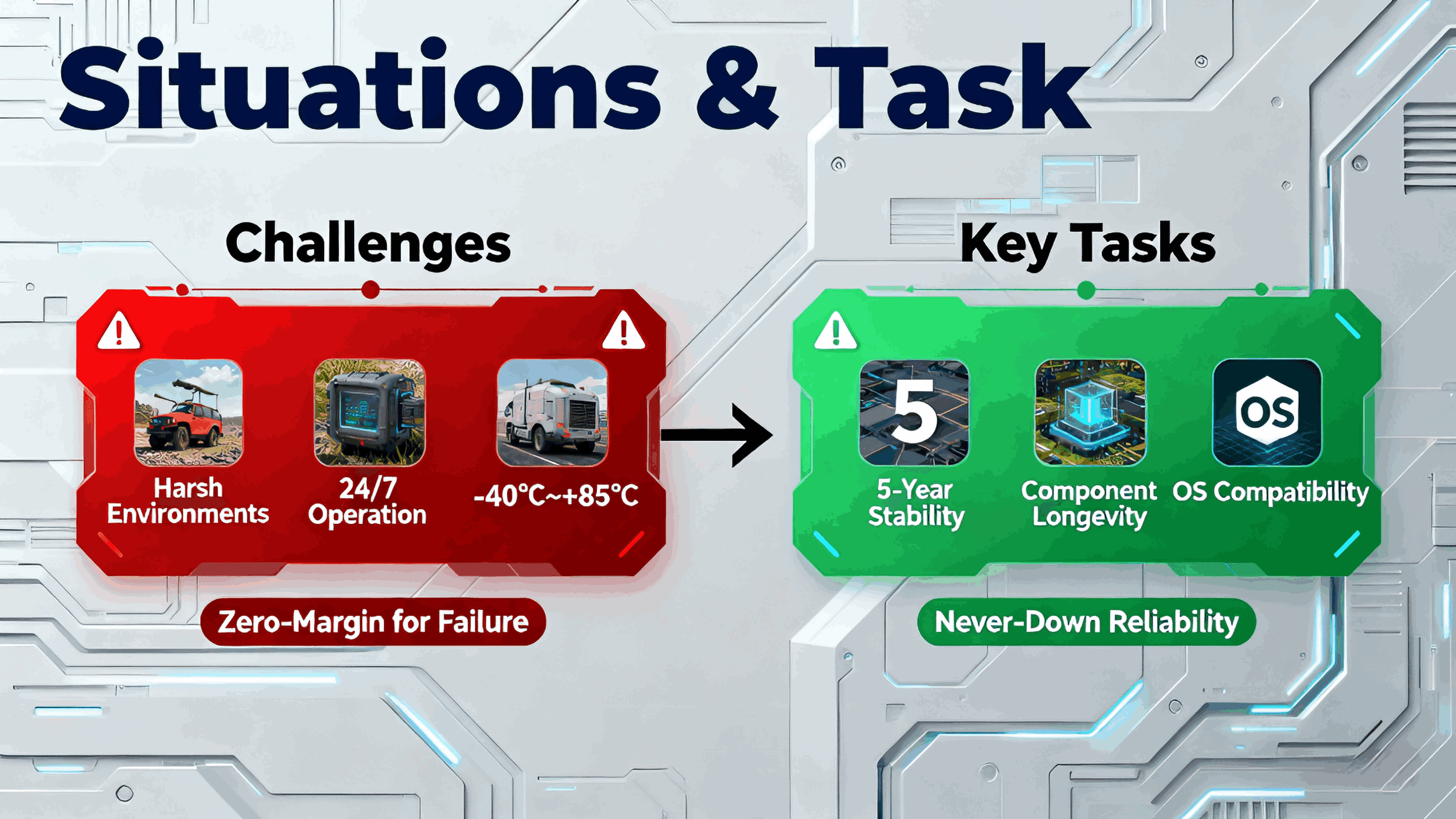

A STAR-Framework Case Study on Large-Scale Reliability Engineering failure is not a technical issue—it is a financial and operational disaster 10,000+ edge nodes across factories, warehouses, and smart city terminals “We need a platform that simply does not fail—ever.” zero critical hardware failures howSTAR framework (Situation, Task, Action, Result) 1. S — Situation: A Deployment With Zero-Margin for Failure The client, a major Industrial IoT solution provider serving automation, energy, and municipal infrastructure systems, needed: harsh industrial environments 24/7 workloads –40°C to +85°C Data integrity for sensor fusion, AI inference, and field processing 5+ years Any failure—whether caused by heat, vibration, aging components, or firmware instability—would require costly field replacement and risk contractual penalties. The client had tried several off-the-shelf motherboards but encountered: PCB warping in high heat NVMe instability under vibration Power failure caused by VRM thermal fatigue Firmware incompatibility with Linux/RTOS platforms Shenzhen Angxun Technology Co., Ltd. 2. T — Task: Build a Platform With “Never-Down Reliability” The client’s technical requirements included: 1. Industrial-Grade Hardware Stability 24/7 continuous operation 100% pass rate under temperature shock (-40°C ⇄ +85°C) Vibration and humidity tolerance 2. Long-Term Component Availability 5–7 years lifecycle guarantee No BOM changes that break software compatibility 3. Firmware & OS Compatibility Linux variants (Ubuntu, Debian, Yocto, OpenWRT) Windows IoT Real-time OS support for edge devices 4. Massive, Distributed Deployment Support 10,000+ nodes Remote monitoring, firmware roll-back capability Consistent production quality over several years The task was clear: Engineer a motherboard platform built for scale, time, and extreme reliability. 3. A — Action: How Angxun Engineered Mission-Critical Reliability 3.1 Component-Level Reliability Engineering Our engineering team redesigned the board using: All-solid capacitors Enhanced copper plating Independent CPU VRM power rails Industrial-grade clock generators and MOSFETs Zero-burning protection circuits Every component was derated for temperature, voltage, and long-term drift. 3.2 Environmental Hardening The platform was validated through: Wide-temperature testing (-40°C to +85°C) 72-hour burn-in tests Vibration tests (10–500Hz) Humidity & dust endurance tests (up to 95% RH) Long-duration power cycling This exceeded the requirements for typical industrial PCs and IoT gateways. 3.3 Firmware & OS Stability Engineering We built a unified firmware package: BIOS & EC code hardened for 24/7 workloads NVMe and SATA firmware validated for industrial duty SR-IOV, PCIe error recovery, and memory training optimized Full Linux HCL test matrix (kernel 4.x to 6.x) a safe firmware rollback mechanism 3.4 Manufacturing for Consistency at Scale Angxun’s factory strength ensured long-term consistency: 10,000㎡ factory Five SMT lines 300,000+ motherboards CE, FCC, RoHS, ISO-certified production exact same BOM 3.5 Lifecycle & Support Infrastructure To support 10,000+ globally deployed nodes, we built: component lifecycle map component-level traceability system 24/7 engineering escalation support Batch-level firmware release control This eliminated field surprises and ensured long-term operational stability. 4. R — Result: 10,000+ Nodes, 5 Years, Zero Critical Failures After deployment, the outcome speaks for itself: Zero critical hardware failures across 10,000+ nodes 99.98% uptime per node No field replacements caused by VRM, DDR, NVMe, or power failure Zero unplanned firmware rollback events Client reduced TCO by 37% Deployment expanded to new cities using the same Angxun platform This performance became a key competitive advantage for the client’s Industrial IoT solution. Conclusion: “Never-Down Reliability” Is Engineered—Not Claimed The success of this 10,000+ node deployment is not luck. It is the result of: Component-level reliability engineering Industrial-grade circuit design Extreme environmental validation Consistent, long-term manufacturing discipline Firmware stability and support infrastructure At Shenzhen Angxun Technology, reliability is not a marketing term— it is embedded into the engineering DNA of every product we build. mission-critical, long-term deployments

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat