How We Maintain Outstanding Reliability While Delivering Competitive Pricing for White-Label Server Brands

In the white-label server and motherboard industry, customers often assume that lower prices come at the cost of lower quality. But at Shenzhen Angxun Technology Co., Ltd., we operate on a different philosophy:

Affordable does not mean inferior — and cost efficiency must never come at the expense of reliability.

Our “Hero Product Quality Assurance System” is engineered to deliver stable, high-performance, and cost-optimized hardware that global OEMs, system integrators, and distributors can trust. This article reveals the processes, testing standards, and quality controls that make this possible.

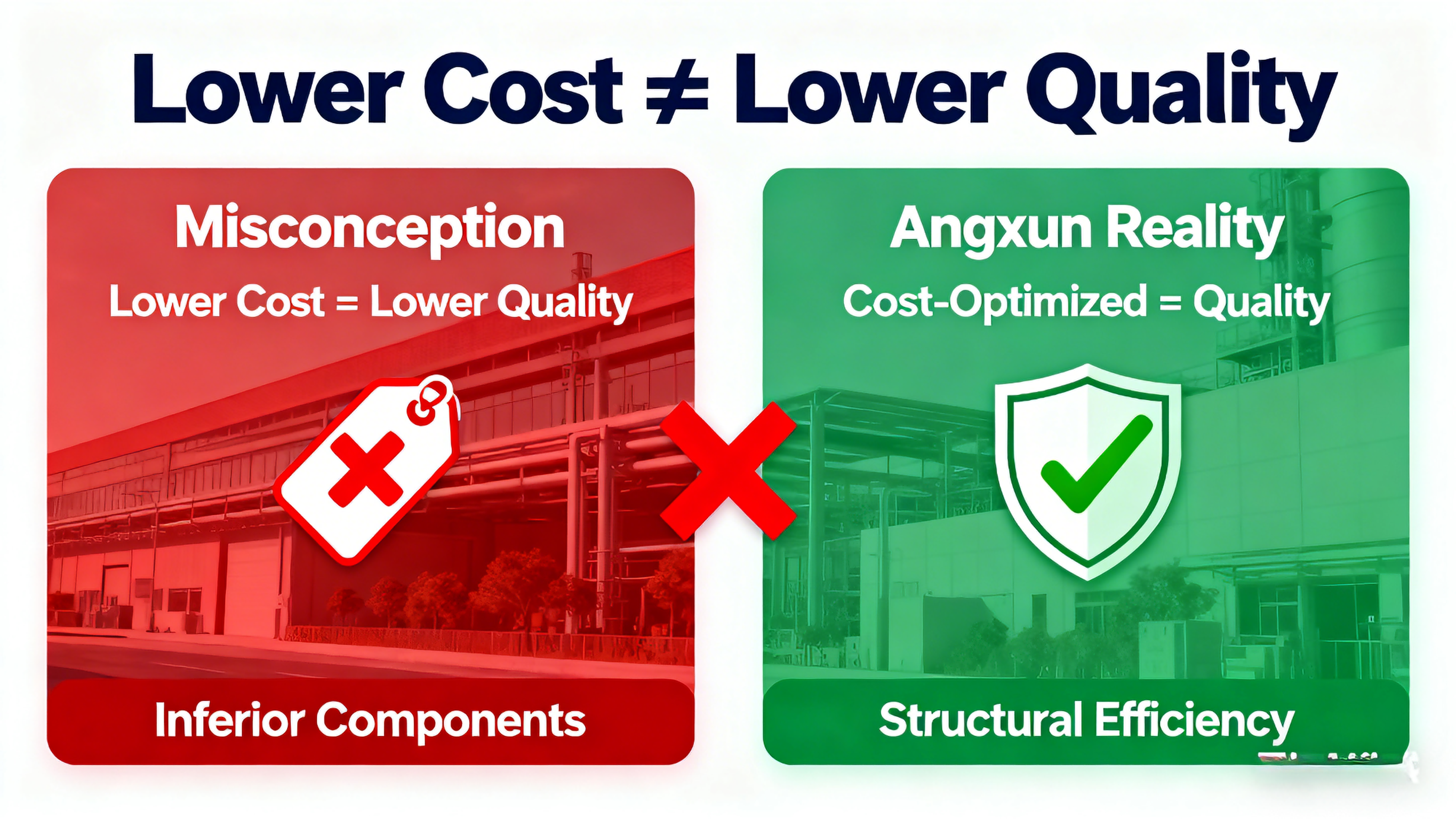

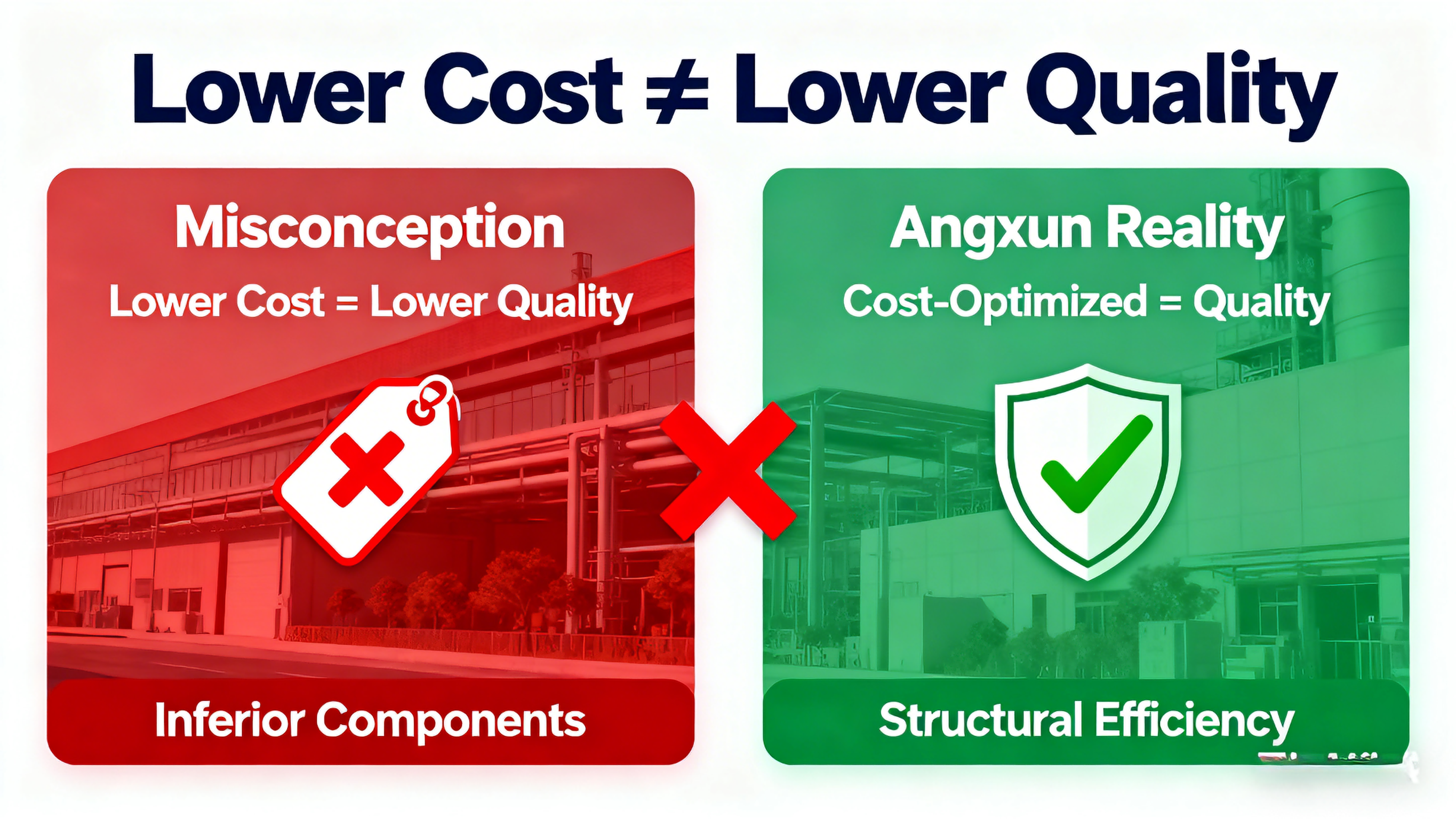

1. The Principle: Lower Cost ≠ Lower Quality

Angxun’s cost advantage does not come from compromising components, skipping testing, or reducing labor.

Instead, it comes from:

Integrated SMT + DIP + assembly lines

Multi-model component reuse

Long-term component supplier partnerships

Lean manufacturing and waste reduction

Engineering-first design philosophy

Automation to reduce human error

These measures reduce cost structurally, not at the expense of reliability.

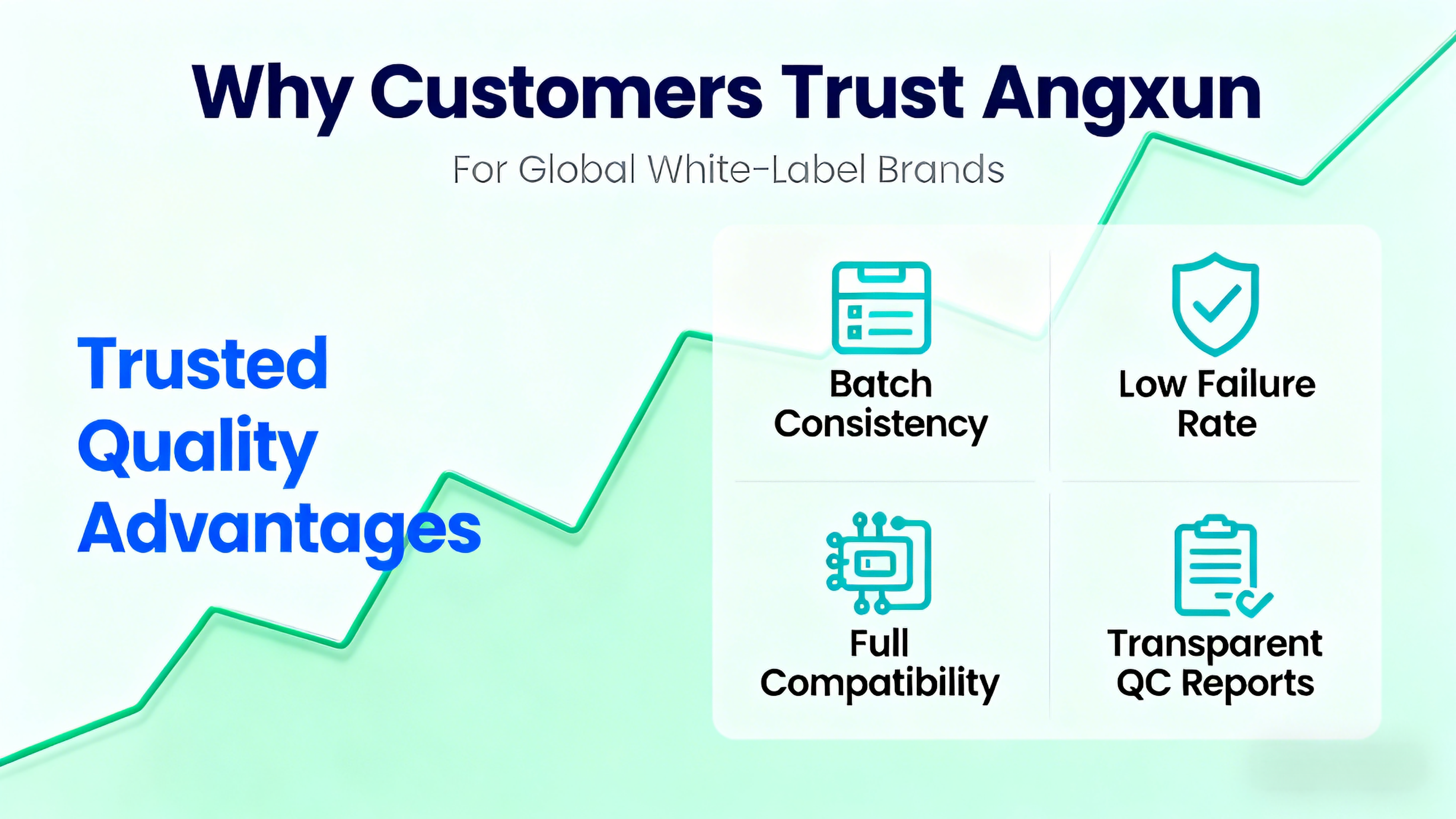

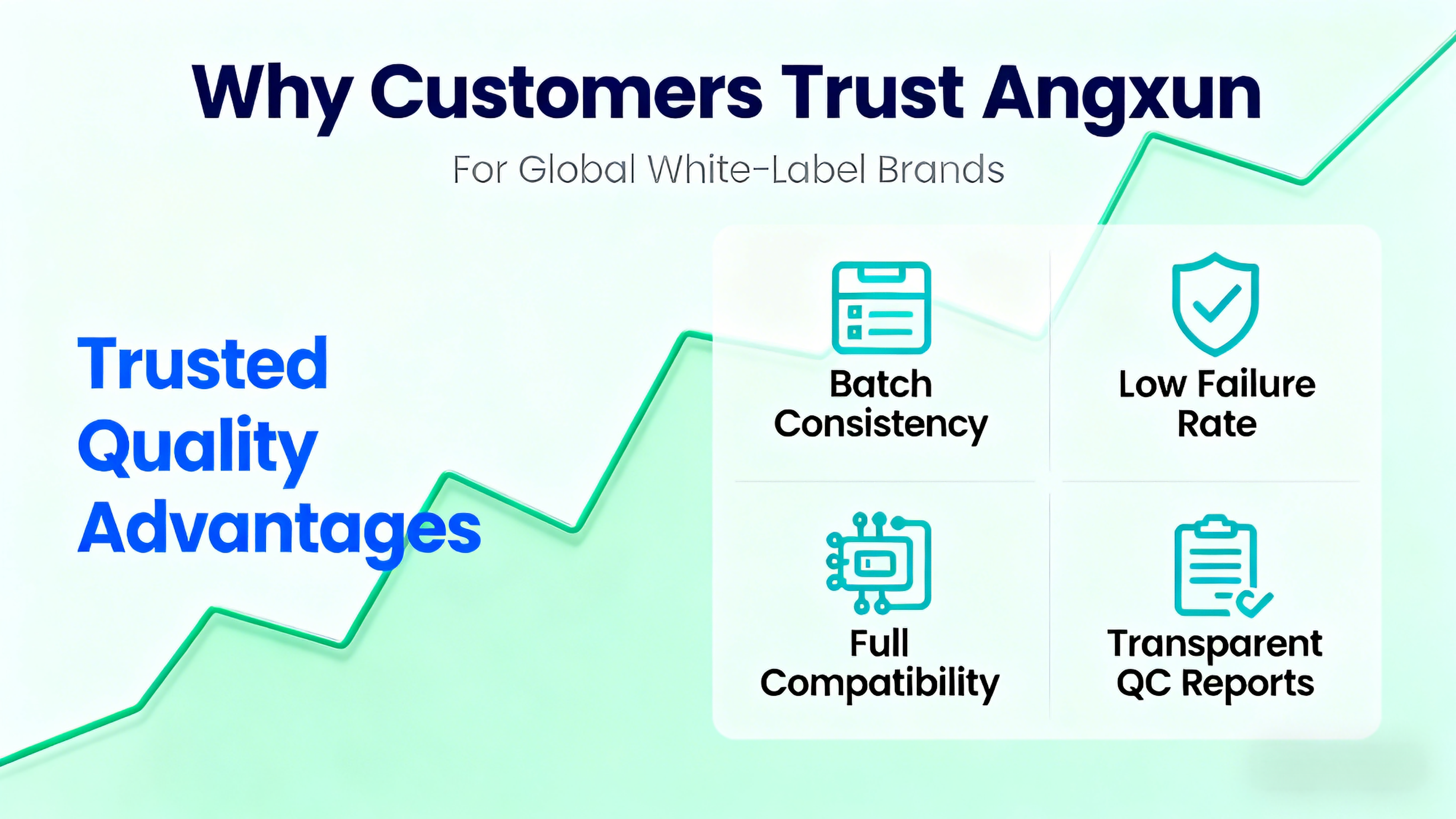

2. Our “Hero Product” Philosophy

A “Hero Product” is a motherboard model that achieves:

High reliability across large volumes

Minimum failure rates in field deployment

Strong compatibility across CPU, RAM, GPU, NIC, SSD

Consistent performance across batches

Predictable supply for 24–36 months

These products become the backbone of our white-label customers’ portfolios, enabling stable sales and easy after-sales management.

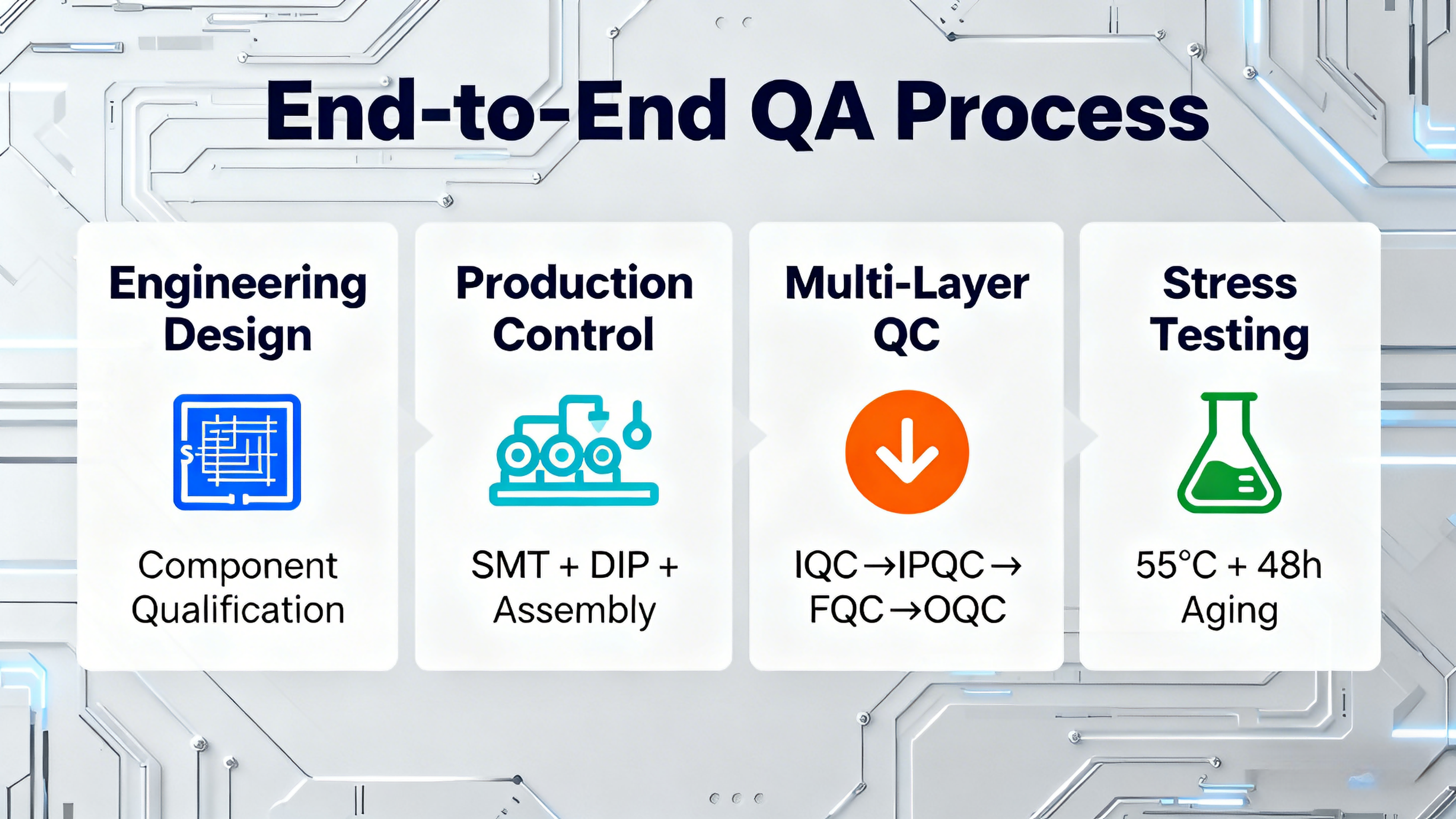

3. Quality Assurance Begins at Engineering

Great manufacturing starts with great engineering. Before a product enters mass production, Angxun performs:

✔ Component Selection & Qualification

Every IC, capacitor, power stage, and chipset is validated for:

Stability

Temperature tolerance

Vendor consistency

Long-term availability

✔ Circuit-level Reliability Engineering

Including power integrity simulation, signal integrity analysis, and EMI validation.

✔ Pre-Validation for Configuration Compatibility

We test against:

This reduces integration risk and saves customers 200+ testing hours.

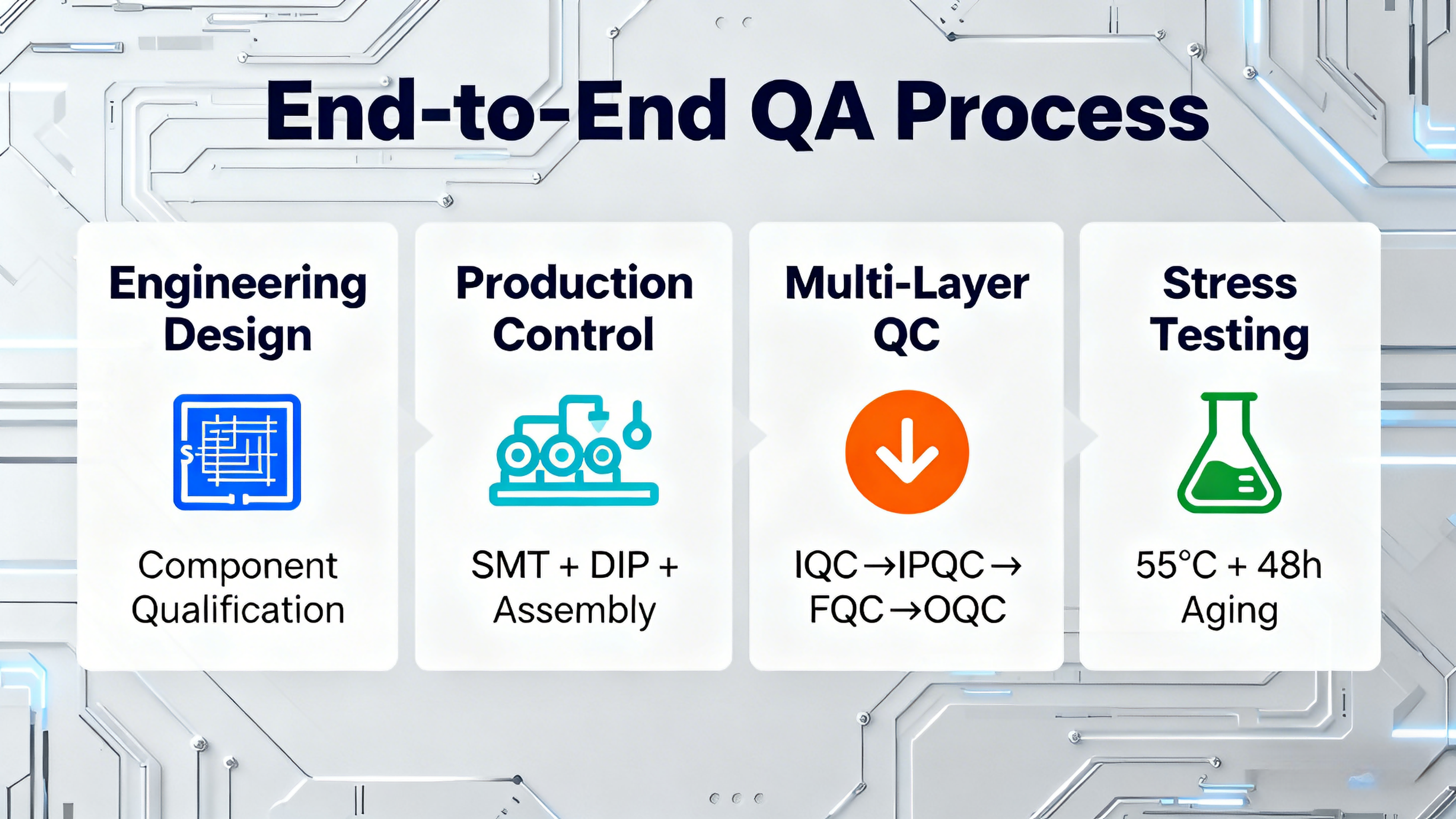

4. SMT + DIP + Assembly: Full-Process Production Control

Angxun’s manufacturing uses a vertically integrated workflow:

SMT (Surface Mount Technology) Lines

Automated stencil printing

Real-time AOI inspection

High-precision pick-and-place

Reflow soldering with temperature curve monitoring

DIP (Through-Hole) Process

Assembly + Burn-in

BIOS flashing and hardware pairing

Thermal performance validation

Board-level powering and boot cycles

This integration means no outsourcing, no hidden steps, and no uncertainty in quality.

5. Multi-Layer Quality Control: Our Standard Testing Framework

Every motherboard goes through a layered QC system that eliminates defects before shipment.

(A) IQC — Incoming Quality Control

Component appearance and packaging checks

Electrical parameter verification

Batch traceability

Vendor performance scoring

(B) IPQC — In-Process Quality Control

(C) FQC — Final Quality Control

Performed after full assembly.

Includes:

POST & boot stability tests

Memory stress tests

PCIe, SATA, M.2, USB functional checks

Thermal response testing

BIOS configuration validation

(D) OQC — Outgoing Quality Control

Before shipping to customers:

Random sampling per AQL standard

12–24 hour burn-in on selected units

Packaging integrity testing

Serial number + lot tracking

These combined steps ensure batch-level consistency that white-label customers depend on.

6. Stress Testing: The Core of Our Reliability Guarantee

To ensure long-term performance, we apply industrial-grade stress tests:

✔ High-temperature aging (up to 55°C)

✔ CPU + RAM load testing

✔ Voltage fluctuation tolerance tests

✔ Cold start / warm start cycling

✔ Full interface hot-plug tests

✔ Long-duration stability running (12–48 hours)

✔ BIOS recovery / flash stability validation

These test conditions simulate years of real-world field usage.

7. Quality Root Cause Analysis: No Guesswork Allowed

If any failure occurs inside the factory, we execute a strict RCA workflow:

5-Why root cause analysis

Component failure microscopy

Circuit-level fault duplication

Supplier escalation when needed

Preventive action for next batch

Permanent corrective action (PCA) tracking

This prevents repeated issues and supports long-term model stability.

8. Cost Control Without Cutting Corners

How do we maintain competitive pricing while keeping strict quality?

✔ Large-scale production reduces per-unit overhead

✔ Long-term component contracts stabilize pricing

✔ Lean manufacturing cuts waste—not quality

✔ In-house engineering avoids external consulting costs

✔ Process automation reduces scrap rate and rework

The result: