Anyone who has ever priced out a custom motherboard knows this feeling:

“Why is the NRE so high?”

“Why does a small change cost hundreds or thousands of dollars?”

“Why does a low-volume board cost more than a retail board?”

The truth is: hardware customization is expensive not because manufacturers want it to be, but because electronics development has real, unavoidable engineering and production costs.

As a company that has been building Intel/AMD motherboards and industrial platforms for 24 years at Shenzhen Angxun Technology Co., Ltd., we’ve seen these questions on every OEM/ODM project.

So here’s a clean, honest, engineering-level breakdown of where the money actually goes when you customize a motherboard.

1. NRE (Non-Recurring Engineering): The Invisible but Essential Cost

Most new customers underestimate NRE because it’s not a physical part.

But it’s the foundation of the entire project.

Typical NRE includes:

Electrical schematic design

PCB layout (4–10 layers, high-speed routing, impedance control)

Signal integrity simulation

Power delivery design (VRM, protection circuits)

BIOS customization

EC firmware development

Mechanical design / ID adjustments

DFM/DFT review

Engineering labor hours

Engineering samples (EVT/DVT prototypes)

NRE can easily be 30–40% of the total project cost for low-volume orders.

High-speed Intel/AMD platforms require long design hours — not black magic, just expensive engineering time.

2. BOM Cost (Bill of Materials): The Hard Reality of Components

This is the cost you can see: chips, connectors, PCB, power components, etc.

Main contributors to BOM:

CPU socket (LGA / AM5)

Chipset / PCH

PCB cost (especially 6-layer and 10-layer boards)

Power delivery components (MOSFETs, inductors, capacitors)

High-quality all-solid capacitors

Copper plating layers

LAN controllers / PHY chips

HDMI/DP ICs

USB controllers

VRM cooling solutions

Aluminum-base thermal architecture

Connectors (surprisingly expensive at scale)

Safety components & fuses

Some customers assume “small changes” mean “cheap,” but even:

…can change the BOM significantly due to supply-chain availability.

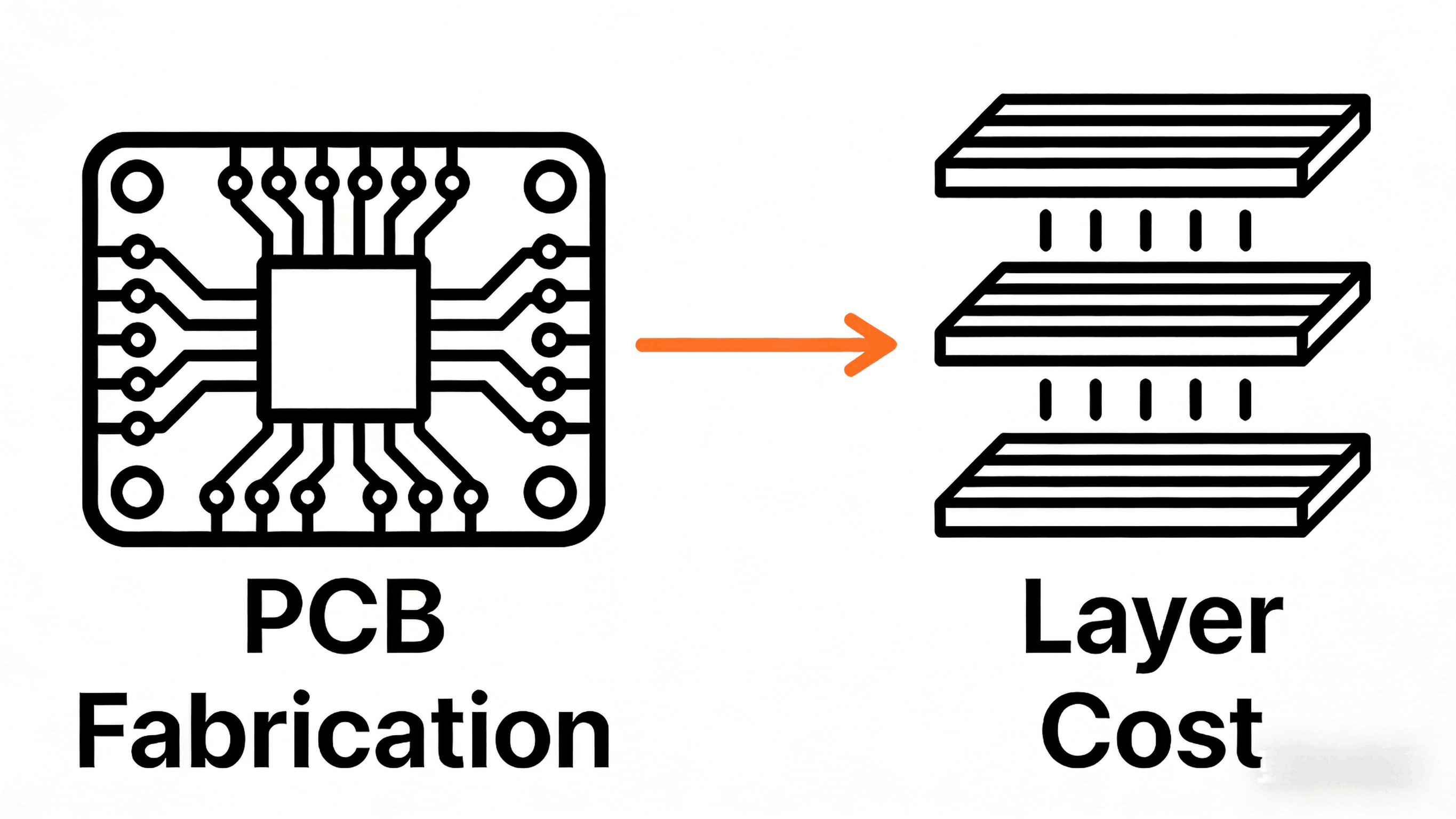

3. PCB Fabrication Cost

This is especially important for industrial boards.

Factors affecting PCB cost:

Number of layers (common: 6 or 8)

Copper thickness

HDI requirements

Impedance-controlled routing

Via-in-pad process

Material type (FR4 standard vs. high-TG vs. halogen-free)

Panelization efficiency

Complex motherboards often require high-TG PCBs + thick copper — not cheap.

4. BIOS & Firmware Customization

BIOS work is usually underestimated.

What BIOS customization includes:

BIOS logo and visual branding

Boot-order rules and lockdown

Security settings

TDP/power tuning

Port enable/disable

ACPI tuning for OS behavior

TPM / secure boot implementation

Compatibility patches for specific RAM / SSD / NIC vendors

Firmware development requires specialized engineers — and mistakes can brick devices.