If you are a desktop computer motherboard brand manufacturer (or an OEM/ODM client) sourcing production from China, choosing the right factory is absolutely critical. Motherboards are complex products that rely on precision engineering, stable component supply chains, strict quality control, and ongoing firmware support — so not every factory can handle that well.

Here is a comprehensive list of factors and due diligence steps you need to consider.

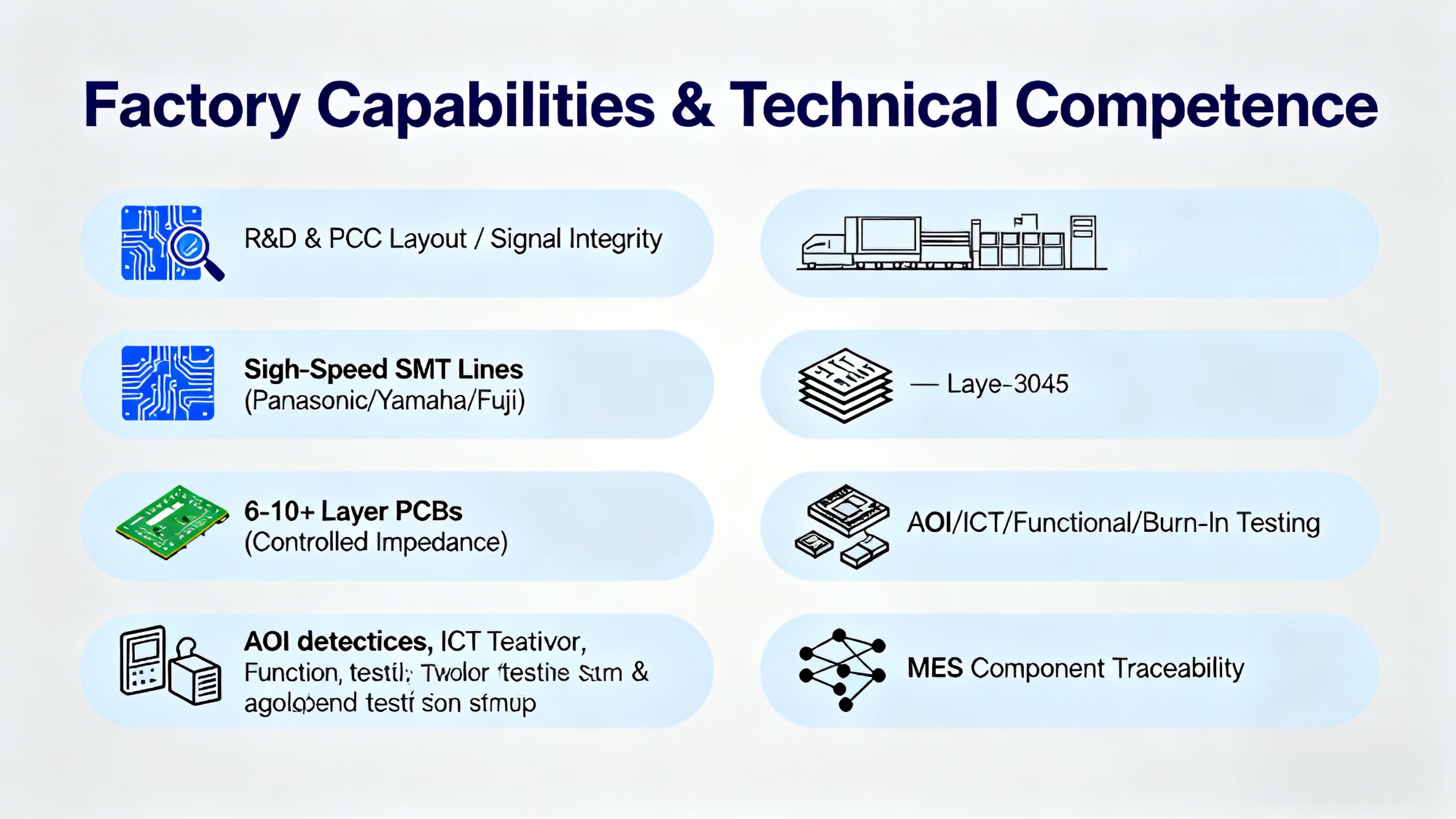

1. Factory Capabilities & Technical Competence

What to Evaluate:

R&D and Design Capability – Can the factory handle schematic/PCB layout, signal integrity analysis, and power delivery design in-house, or must you provide complete design files?

SMT Line Specifications – Number of high-speed SMT (Surface Mount Technology) lines. Types of machines used (e.g., Panasonic, Yamaha, Fuji).

Multi-layer PCB Capability – Can they produce multilayer PCBs (6, 8, 10+ layers) with controlled impedance and differential pair routing for DDR, PCIe, etc.?

Testing Equipment – Availability of AOI (Automatic Optical Inspection), ICT (In-Circuit Test), functional testing, burn-in testing, and BIOS verification stations.

Component Traceability – Do they use an MES (Manufacturing Execution System) or barcode tracking to trace every component batch and board?

Why It Matters:

A low-end PCB assembler might suffice for simple boards, but they are unsuitable for complex DDR5, PCIe 5.0, or CPU socket boards that demand precise signal integrity and firmware integration.

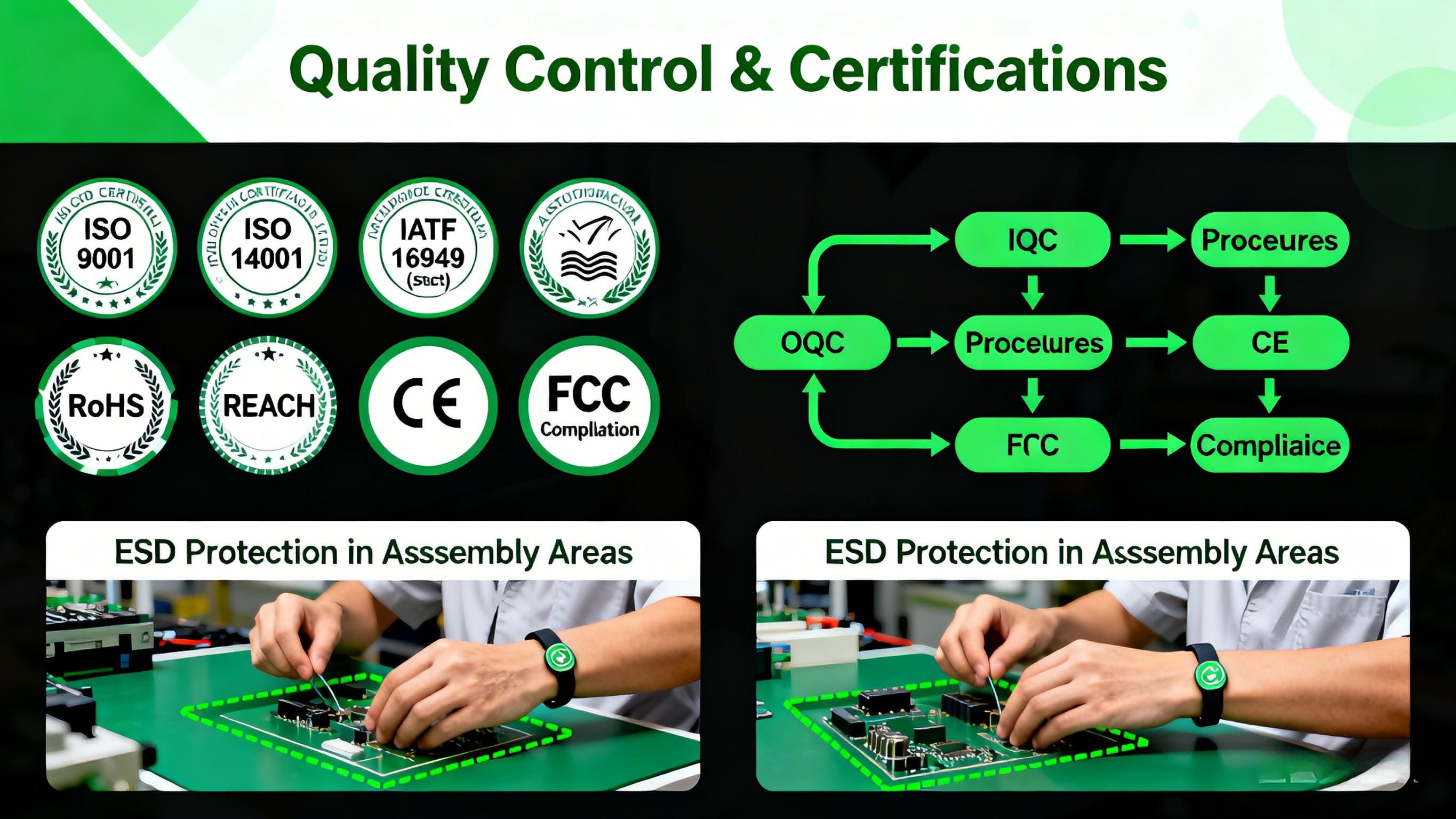

2. Quality Control & Certifications

Check For:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

IATF 16949 (Automotive Electronics – a strong indicator of superior QA maturity, even if not required for your product)

RoHS / REACH / CE / FCC Compliance

Robust Incoming Quality Control (IQC) and Outgoing Quality Control (OQC) procedures.

ESD (Electrostatic Discharge) protection throughout the assembly areas.

Why It Matters:

Quality consistency is paramount for long-term reliability. These certifications and systems demonstrate the factory's ability to maintain stable quality across thousands of boards per month.

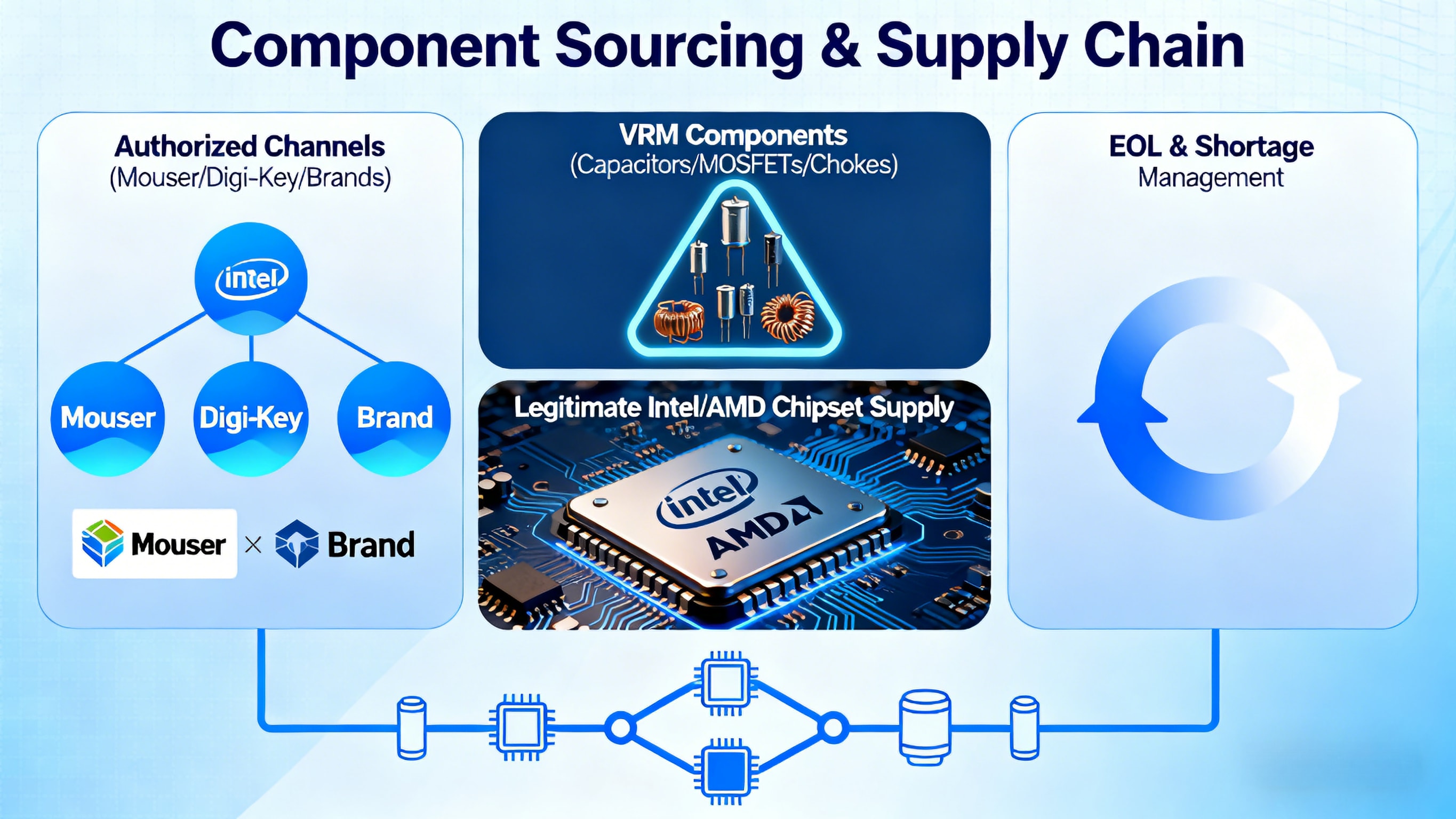

3. Component Sourcing and Supply Chain Stability

Ask About:

Authorized Component Channels – Do they purchase from franchised distributors like Mouser, Digi-Key, or directly from manufacturers, or do they rely on local brokers?

VRM Component Sourcing – The brands and sources for critical components like capacitors, MOSFETs, chokes, and controllers.

Chipset Procurement – For Intel/AMD platforms, verify they have legitimate supply authorization.

Inventory Management System – How they handle component shortages and End-of-Life (EOL) parts.

Why It Matters:

Unofficial or grey-market chips (especially chipsets or BIOS ICs) can cause unstable or incompatible boards, destroying your brand reputation.

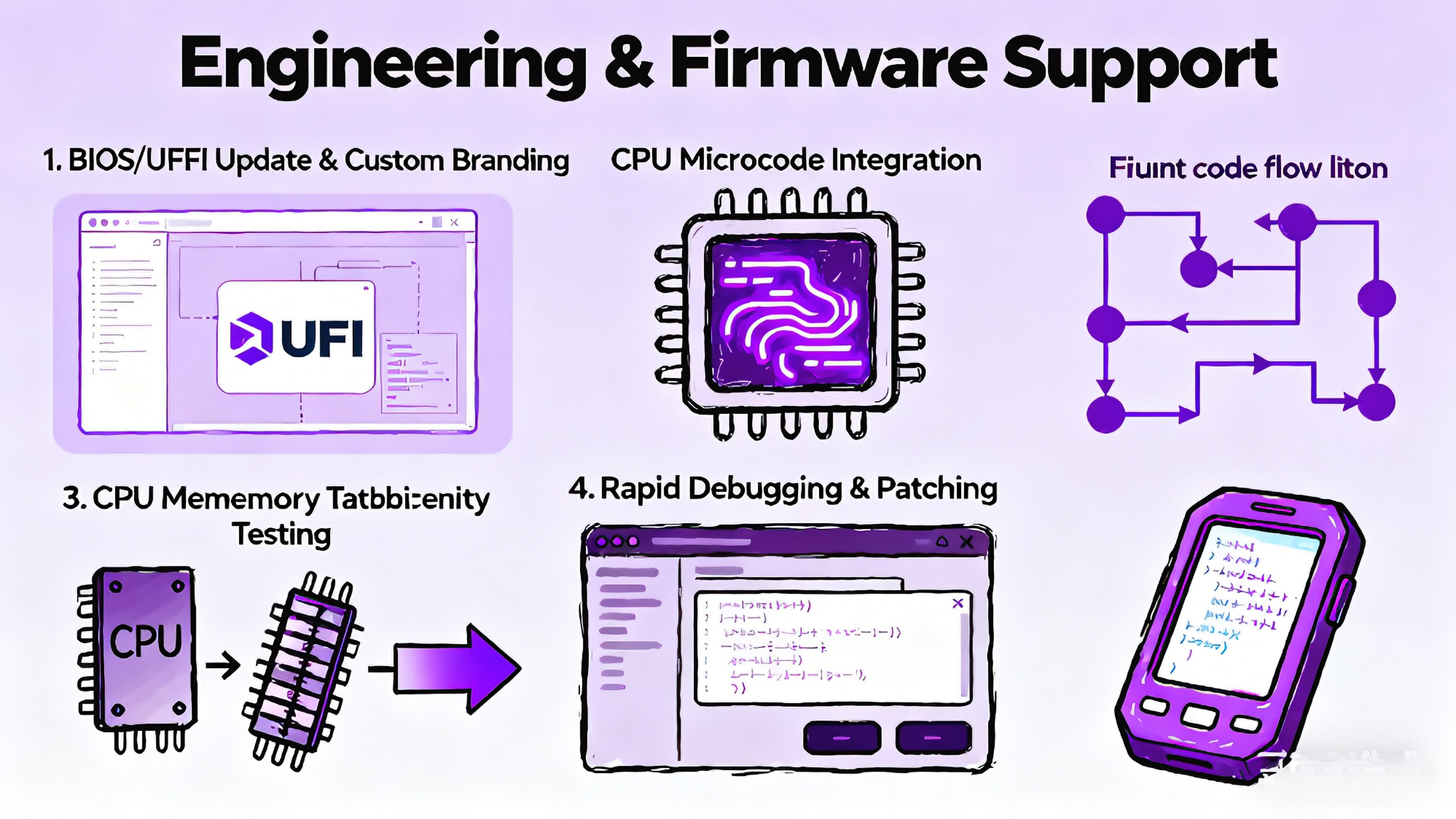

4. Engineering Support & BIOS / Firmware Capabilities

Evaluate:

Does the factory have in-house firmware engineers capable of maintaining and updating BIOS/UEFI?

Can they perform custom BIOS branding and integrate new CPU microcode?

What is their process for CPU and memory compatibility testing?

Are they capable of rapid debugging and issuing firmware patches?

Why It Matters:

Motherboard performance is heavily dependent on BIOS quality. Perfect hardware will fail with poor firmware support.

5. Cost, MOQ, and Production Scalability

Ask About:

MOQ (Minimum Order Quantity) – Typically ranges from 100 to 1,000 units for mid-tier OEMs.

Detailed Cost Breakdown – PCB fabrication, assembly, testing, packaging, firmware, and logistics.

Production Scalability – Can they scale seamlessly from prototype runs (100-500 pcs) to mass production (10,000+ pcs) without significant lead time increases?

Payment Terms – Standard terms (e.g., 30% deposit, 70% before shipment), Letter of Credit, or escrow options.

Why It Matters:

Balancing cost and quality is essential. The lowest bid is often the most expensive choice for high-complexity products due to reliability issues.

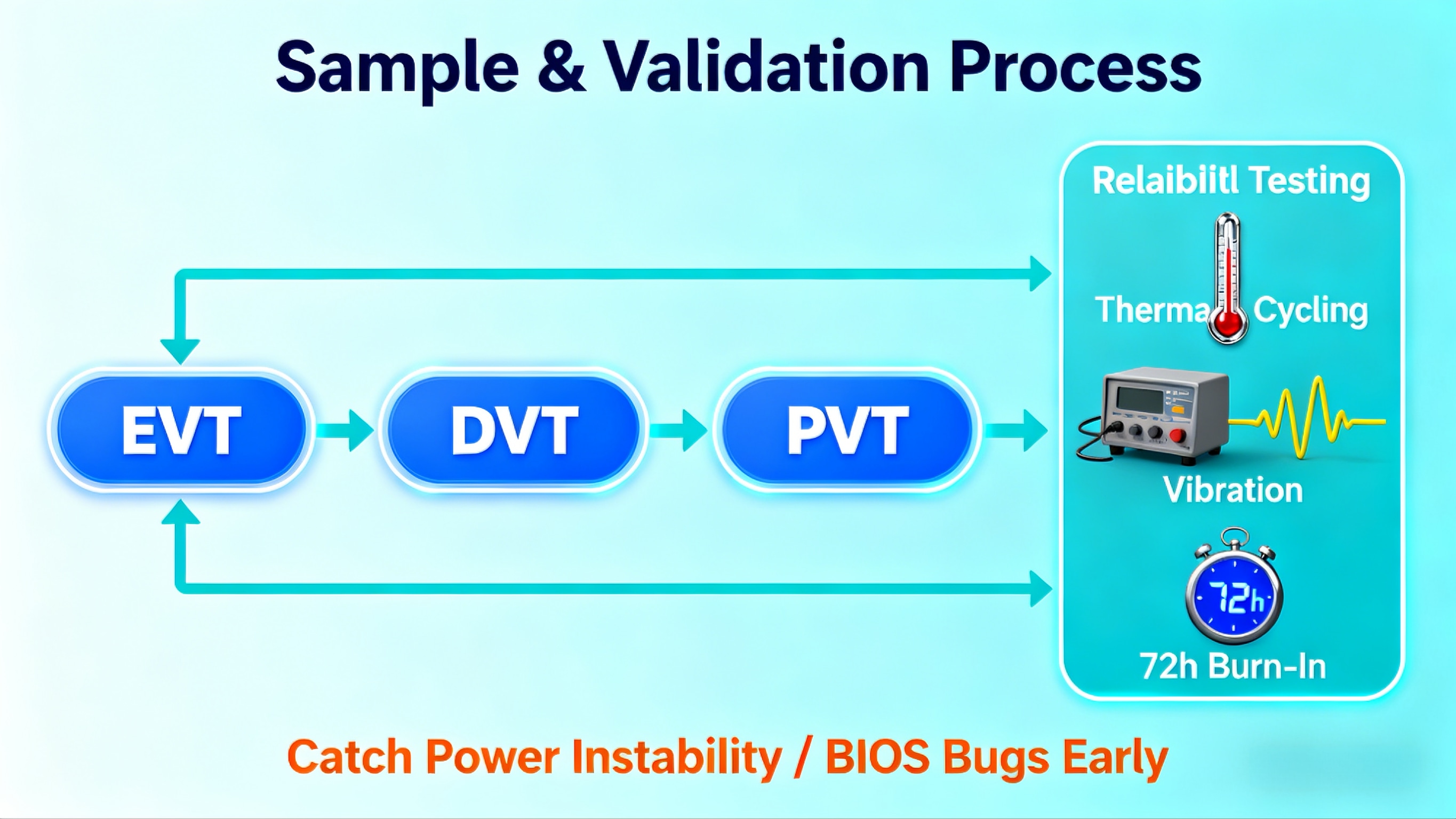

6. Sample & Validation Process

Before signing any contract, insist on a rigorous validation process:

EVT (Engineering Validation Test) – Verifies basic design functionality.

DVT (Design Validation Test) – Tests performance under various loads and environmental conditions.

PVT (Production Validation Test) – Confirms the manufacturing process is reproducible and stable.

Reliability Testing – Including thermal cycling, vibration, and extended burn-in (e.g., 72 hours).

This process is critical for catching power instability, component mismatches, or BIOS bugs before full-scale production begins.

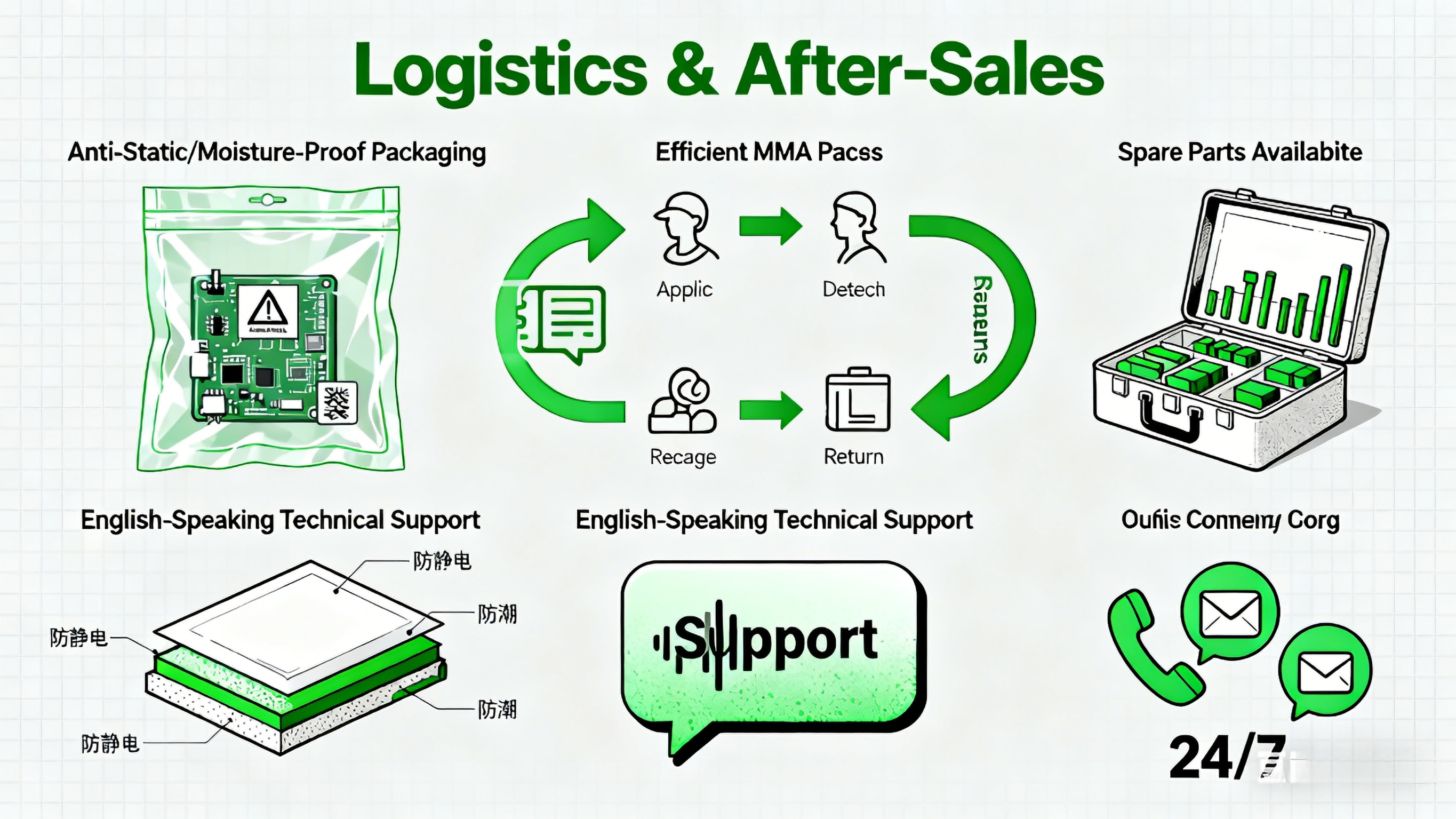

7. Logistics, After-Sales, and Warranty Handling

Key Considerations:

Packaging Quality – Anti-static, moisture-proof, and sufficient cushioning.

RMA (Return Merchandise Authorization) Process – Efficiency in handling returns and repairs.

Spare Parts Availability – For components like BIOS chips and power MOSFETs.

Local Support – Availability of English-speaking technical staff or overseas service partners.

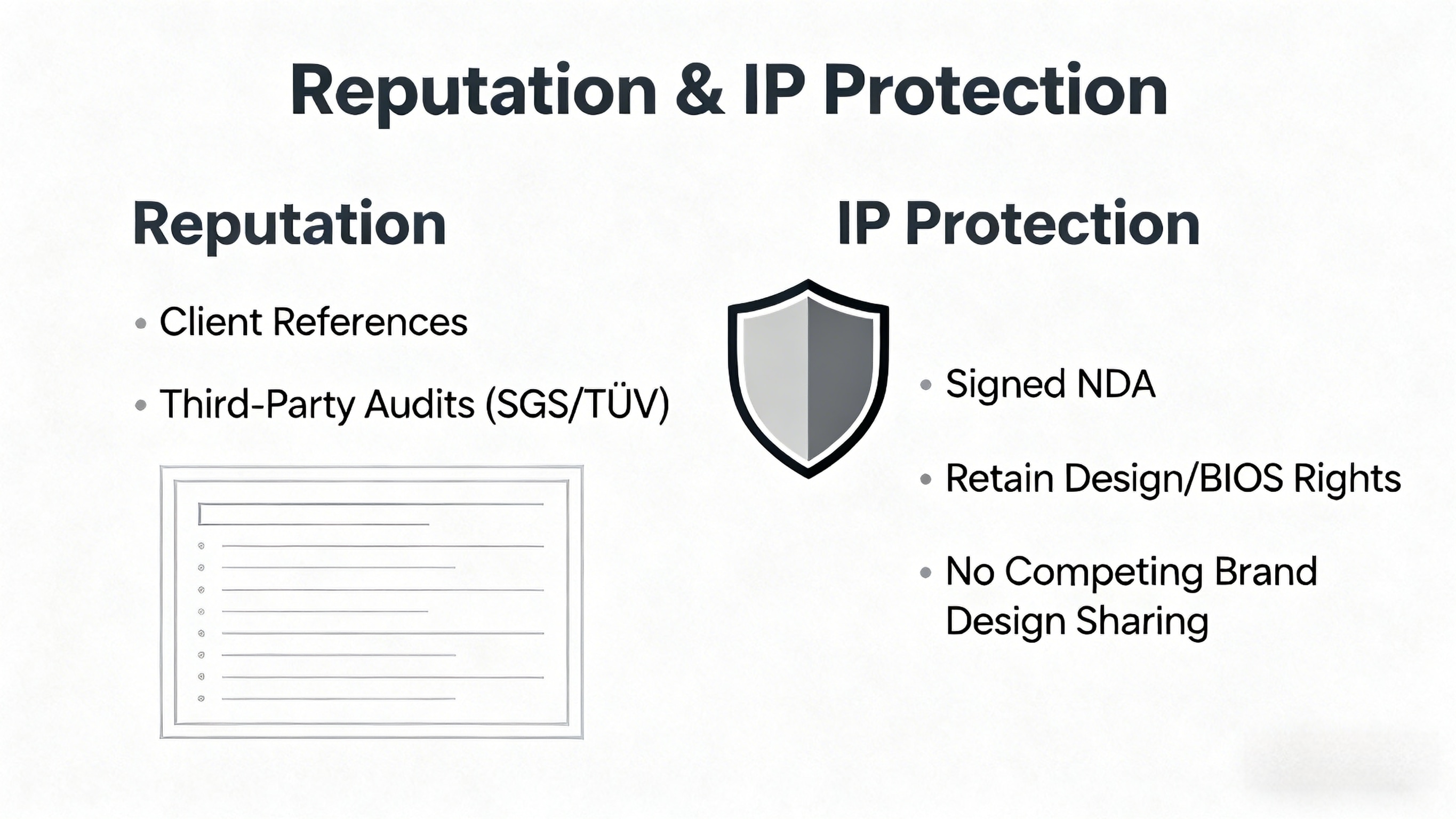

8. Reputation & References

Due Diligence Steps:

Ask for client references, especially from known brands.

Research online feedback on platforms like Reddit, Baidu, or Alibaba.

If possible, conduct a factory audit—either by visiting yourself or hiring a third-party quality control firm (e.g., SGS, TÜV, AsiaInspection).

9. Location Advantage

Primary Manufacturing Hubs:

Shenzhen / Dongguan (Guangdong) – The heart of consumer electronics and OEM/ODM manufacturing.

Suzhou / Kunshan (Jiangsu) – Hosts many large-tier factories supplying global brands.

Chengdu / Chongqing – A growing hub for some industrial board production.

Selecting a factory near your component suppliers or a major port reduces lead times and lowers logistics risks.

10. Intellectual Property (IP) Protection

Critical Actions:

Ensure a robust NDA is signed before sharing any schematics or firmware.

Clarify and contractually define ownership of all design files—you must retain rights to PCB layouts, BIOS, and other IP.

Inquire if they manufacture for competing brands using similar base designs to assess potential conflict.

Summary Evaluation Table

Factor Why It Matters What to Verify Factory Capability Ensures technical ability SMT line specs, PCB layer capacity QA System Prevents defects ISO9001, AOI, burn-in, traceability Component Sourcing Reliability & legality Authorized distributors Firmware Support Compatibility & stability BIOS engineering team Cost & MOQ Budget planning Prototype-to-mass-production flexibility Testing Ensures consistency EVT/DVT/PVT reports Logistics Smooth delivery Packaging & RMA policy Reputation Risk management Client references, factory audit Location Efficiency Access to suppliers & shipping IP Protection Protect your brand NDA, design file ownership

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat