That mysterious crash that cost your factory $18,000 in downtime? It wasn't the software. It was dust you could barely see.

We learned this lesson the hard way when a automotive manufacturing client called us in a panic. Their quality control system kept crashing randomly, and they'd already replaced everything from memory to storage. The culprit? Dust accumulation on the PCIe slots that no one had considered.

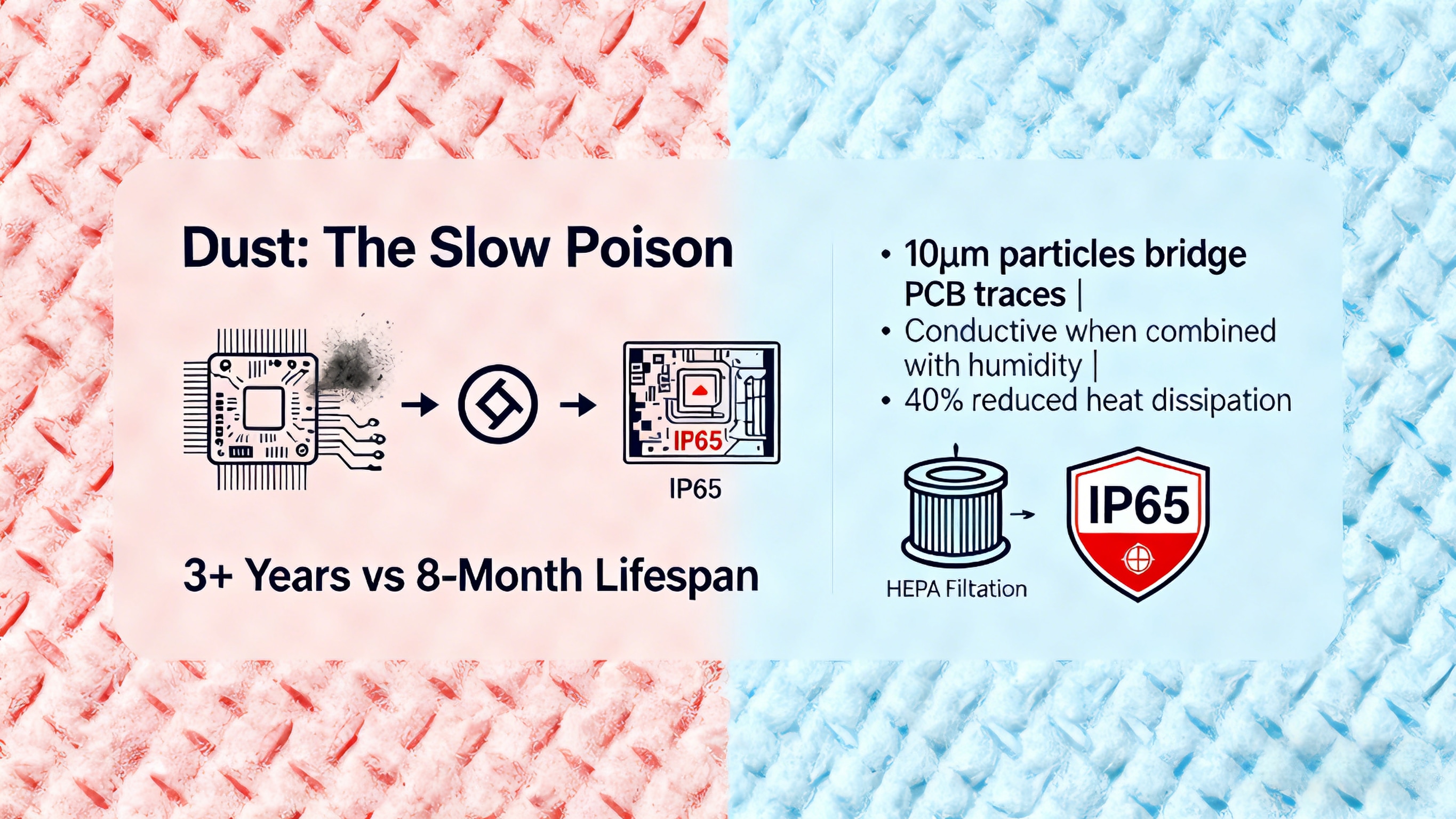

Dust: The Slow Poison

Most IT departments think dust is just a cleaning issue. In industrial environments, it's a system killer.

The Microscopic Reality:

Dust particles as small as 10μm can bridge PCB traces

Combined with humidity, dust becomes conductive

Thermal insulation effect reduces heat dissipation by up to 40%

Our Defense Strategy:

IP65-rated enclosures across our industrial panel PC line

Positive pressure cooling systems with HEPA filtration

Conformal coating on all critical motherboard components

Sealed connectors with silicone gaskets and corrosion-resistant coatings

Real-world example: Our AMD Ryzen Embedded-based industrial PCs running in a cement plant have operated for 3+ years without a single dust-related failure, while competitors' systems average 8-month lifespans.

Vibration: The Invisible Destroyer

Vibration doesn't just loosen connections—it fatigues materials at the molecular level.

The Physics of Failure:

Solder joints crack under repeated stress

PCB traces develop microfractures

Components literally shake themselves loose

Engineering Solutions:

Structural reinforcement with 2.0mm thick PCBs vs standard 1.6mm

Underfill application on BGA components for automotive-grade reliability

Vibration-dampening mounts that absorb 85% of harmonic vibrations

Locking connectors that require positive engagement and audible clicks

We test all our industrial motherboards to MIL-STD-810G standards, including:

5-500Hz vibration sweeps

50G shock testing

3-axis simultaneous vibration exposure

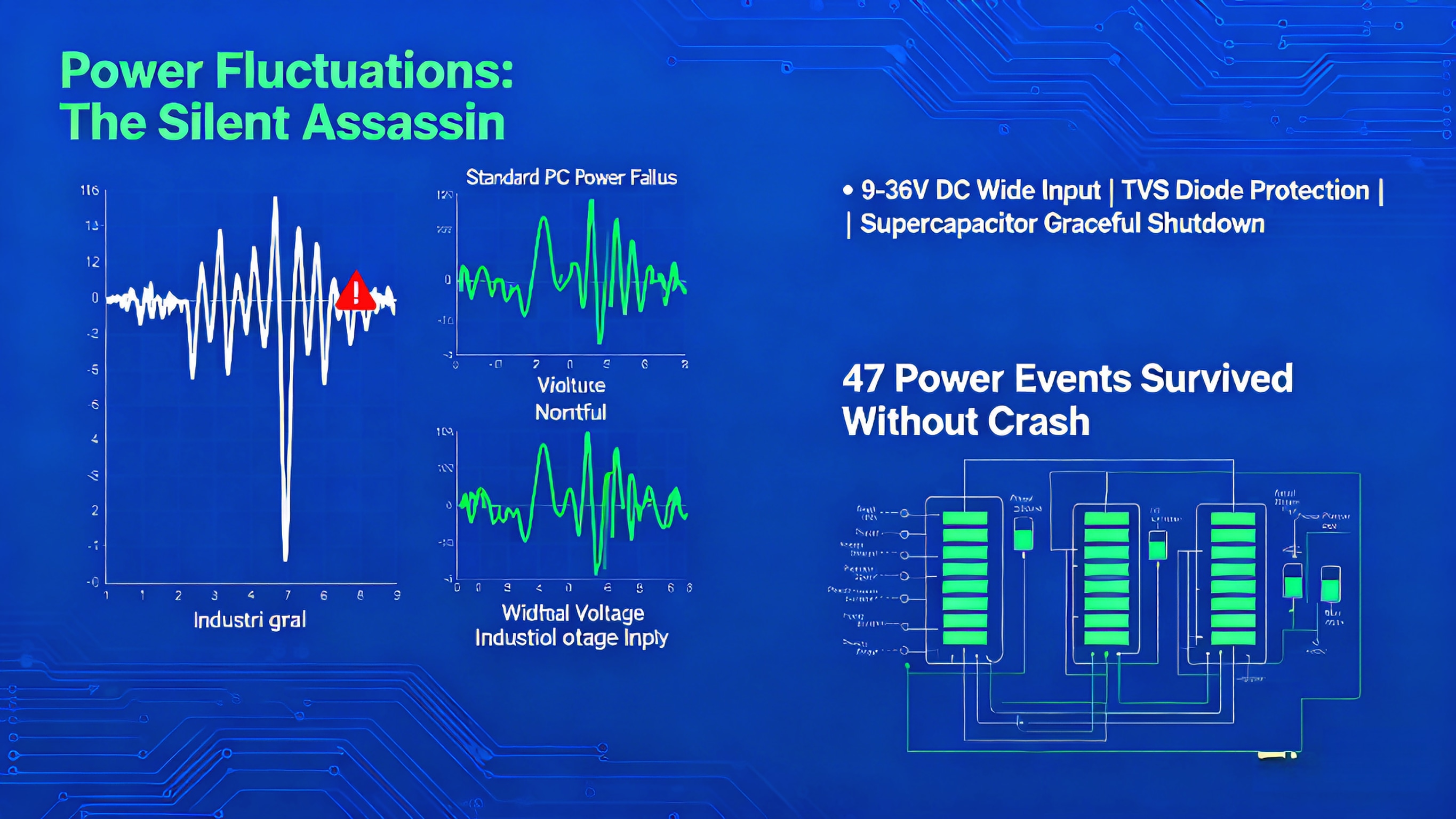

Power Fluctuations: The Silent Assassin

Industrial power is dirty. Really dirty.

The Power Quality Nightmare:

Voltage sags during heavy equipment startup

Harmonic distortion from VFDs and motors

Transient spikes from switching operations

Our Power Protection Arsenal:

Wide voltage input (9-36V DC) on all industrial boards

TVS diodes on all external interfaces

Multi-stage filtering with X/Y capacitors and common-mode chokes

Super capacitors for graceful shutdown during power loss

Case study: A food processing plant using our industrial motherboards survived 47 power quality events in one month without a single system crash.

The Manufacturing Difference: ODM/OEM Perspective

As a motherboard manufacturer, we build protection into the design phase:

Component Selection:

Automotive-grade MOSFETs and capacitors

Industrial-temperature range DDR5 memory

Thicker gold plating (30μ") on connectors

Design Philosophy:

Conservative derating: Components operate at 60% of rated capacity

Redundant power inputs on server-grade boards

Isolated power domains to contain failures

Validation Testing:

1,000+ thermal cycles (-40°C to 85°C)

72-hour power cycling under load

Vibration testing simulating 5 years of operation

Cost of Getting It Wrong

The math is brutal:

Average industrial PC downtime: $5,000/hour

Emergency service call: $2,500+

Production losses: Variable but often 5-10x hardware cost

A $300 "industrial" motherboard that fails in 6 months often costs more than a $900 properly engineered solution that lasts 5+ years.

Your Industrial PC Survival Checklist

When evaluating industrial computing solutions:

Dust Protection

IP54 minimum rating for industrial environments

Positive pressure or fully sealed cooling

Regular maintenance schedule for filters

Vibration Resistance

MIL-STD-810G compliance

Locking connectors on all external interfaces

Vibration-dampened storage mounting

Power Integrity

Wide voltage input range (at least 9-30V DC)

Transient voltage suppression

Power loss protection for graceful shutdown

Manufacturing Quality

Industrial-temperature components

Conformal coating on PCBs

Proven reliability data from manufacturer

The Bottom Line

Industrial environments don't just need "ruggedized" computers—they need systems engineered specifically for their unique challenges. The companies that understand this build protection into every layer, from component selection to final assembly.

Your industrial PC should be the most reliable component in your facility, not the most frequent source of downtime.

We manufacture industrial computing solutions designed to survive real-world industrial environments. Our AMD-based motherboards, industrial PCs, and embedded systems are built with the protection features discussed here. Contact us to discuss your ODM/OEM requirements.

Contact: Tom

Phone: +86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:+86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No. 63, Zhangqi Road, Guixiang Community, Guanlan Street,Shenzhen,Guangdong,China

We chat